- Page 1 and 2:

TM Food Lipids Chemistry, Nutrition

- Page 3 and 4:

FOOD SCIENCE AND TECHNOLOGY A Serie

- Page 5 and 6:

37. Omega-3 Fatty Acids in Health a

- Page 7 and 8:

90. Dairy Technology: Principles of

- Page 9 and 10:

Preface to the Second Edition Reade

- Page 11 and 12:

Preface to the First Edition There

- Page 13 and 14:

Contents Preface to the Second Edit

- Page 15 and 16:

20. Dietary Fats and Coronary Heart

- Page 17 and 18:

J. Bruce German Department of Food

- Page 19 and 20:

1 Nomenclature and Classification o

- Page 21 and 22:

described as 2-methyl-3-phytyl-1,4-

- Page 23 and 24:

Table 3 A Summary of Sequence Prior

- Page 25 and 26:

Table 5 Systematic, Common, and Sho

- Page 27 and 28:

saturation of EFA occurs (primarily

- Page 29 and 30:

Figure 5 Prostaglandin metabolites

- Page 31 and 32:

Figure 7 Prostanoic acid and prosta

- Page 33 and 34:

Figure 9 Eicosenoid isomers in part

- Page 35 and 36:

Figure 10 Nomenclature of cyclic fa

- Page 37 and 38:

Figure 13 Hydroxy fatty acid struct

- Page 39 and 40:

Figure 15 Furanoid fatty acid struc

- Page 41 and 42:

Table 7 Short Abbreviations for Som

- Page 43 and 44:

Figure 20 Steroid nomenclature. rep

- Page 45 and 46:

Figure 22 Cholesterol oxidation pro

- Page 47 and 48:

E. Phosphoglycerides (Phospholipids

- Page 49 and 50:

Figure 26 Glyceroglycolipid structu

- Page 51 and 52:

Figure 28 Structures of some vitami

- Page 53 and 54:

Figure 29 Structures of some vitami

- Page 55 and 56:

Figure 32 Structures of some vitami

- Page 57 and 58:

6. IUPAC. Nomenclature of Organic C

- Page 59 and 60:

2 Chemistry and Function of Phospho

- Page 61 and 62:

variant [1]. Phosphonolipids are ma

- Page 63 and 64:

nonelectrolytes, however, the perme

- Page 65 and 66:

pensations in that enthalpy lost by

- Page 67 and 68:

Table 3 Membrane Deterioration in A

- Page 69 and 70:

erols to generate semisolid or plas

- Page 71 and 72:

The interaction of phospholipids wi

- Page 73 and 74:

fatty acid occurs when Fe 3� at t

- Page 75 and 76:

4. M. C. Blok, L. L. M. van Deenen,

- Page 77 and 78:

47. N. Markova, E. Sparr, L. Wadso,

- Page 79 and 80:

87. R. J. Hsieh. Contribution of li

- Page 81 and 82:

3 Lipid-Based Emulsions and Emulsif

- Page 83 and 84:

may be composed of surface-active c

- Page 85 and 86:

2. Cloud Point When a surfactant so

- Page 87 and 88:

HLB=7� � (hydrophilic group num

- Page 89 and 90:

sion is known as the phase inversio

- Page 91 and 92:

strongly with each other rather tha

- Page 93 and 94:

� = � (1 � 2.5�) (3) 0 wher

- Page 95 and 96:

Figure 8 Biopolymer molecules or ag

- Page 97 and 98:

divide homogenization into two cate

- Page 99 and 100:

2� �P 1 = (4) r where � is th

- Page 101 and 102:

flow rate, decreasing the size of t

- Page 103 and 104:

sion be particularly small, it is u

- Page 105 and 106:

2. Electrostatic Interactions Elect

- Page 107 and 108:

profile of interdroplet pair potent

- Page 109 and 110:

Figure 12 Mechanisms of emulsion in

- Page 111 and 112:

[Eq. (9)], but at high droplet conc

- Page 113 and 114:

alteration in the system’s compos

- Page 115 and 116:

Food emulsions always contain dropl

- Page 117 and 118:

creaming and sedimentation in emuls

- Page 119 and 120:

Foams (E. Dickinson and G. Stainsby

- Page 121 and 122:

4 The Chemistry of Waxes and Sterol

- Page 123 and 124:

Shrinkage and flash point are two f

- Page 125 and 126:

lowing discussion on chemical analy

- Page 127 and 128:

violet chromophore. Application of

- Page 129 and 130:

Figure 1 Examples of naturally occu

- Page 131 and 132:

Scheme 1 Synthesis of mevalonic aci

- Page 133 and 134:

Scheme 3 Synthesis of farnesyl pyro

- Page 135 and 136:

Scheme 6 Biosynthesis of cholestero

- Page 137 and 138:

educe the risk of coronary heart di

- Page 139 and 140:

of cholesterol to bile acids (Schem

- Page 141 and 142:

Scheme 10 Metabolic alterations of

- Page 143 and 144:

sample preparation is usually emplo

- Page 145 and 146:

at levels of 1-100 �g per compone

- Page 147 and 148:

30. H. W. Chen, A. A. Kandutsch, an

- Page 149 and 150:

Biologically Significant Steroids (

- Page 151 and 152:

5 Extraction and Analysis of Lipids

- Page 153 and 154:

preparing nutritional labeling mate

- Page 155 and 156:

polar solvents, such as alkanols, f

- Page 157 and 158:

a ternary system consisting of chlo

- Page 159 and 160:

lipids from meat or hydrolytic prod

- Page 161 and 162:

perature under vacuum. Acid hydroly

- Page 163 and 164:

IV. ANALYSIS OF LIPID EXTRACTS Lipi

- Page 165 and 166:

ments, etc.) primarily involves chr

- Page 167 and 168:

2. Gas Chromatography The GC (or GL

- Page 169 and 170:

4. Supercritical Fluid Chromatograp

- Page 171 and 172:

Table 3 Solvent Systems that Could

- Page 173 and 174:

sibility of determining all compone

- Page 175 and 176:

the isolated trans band is another

- Page 177 and 178:

ionized molecule has the highest m/

- Page 179 and 180:

3. W. R. Bloor. Outline of a classi

- Page 181 and 182:

45. Association of Official Analyti

- Page 183 and 184:

90. M. N. Vaghela and A. Kilara. A

- Page 185 and 186:

132. C. G. Walton, W. M. N. Ratnaya

- Page 187 and 188:

6 Methods for trans Fatty Acid Anal

- Page 189 and 190:

where A = abc (1) 1 A = absorbance

- Page 191 and 192:

methyl elaidate weight equivalents

- Page 193 and 194:

method was modified by inclusion of

- Page 195 and 196:

may be packed or bound to a column,

- Page 197 and 198:

Figure 4 The C-18 region of the gas

- Page 199 and 200:

Table 2 Response Factors of Unsatur

- Page 201 and 202:

Figure 5 Separation of the phenacyl

- Page 203 and 204:

B. Gas Chromatography/IR Spectrosco

- Page 205 and 206:

Figure 7 Expanded IR spectral range

- Page 207 and 208:

CFAMs before converting them to the

- Page 209 and 210:

Figure 8 GC-EIMS chromatographic da

- Page 211 and 212:

flame ionization detection. The fat

- Page 213 and 214:

levels in excess of 50% of the tota

- Page 215 and 216:

22. A. Huang and D. Firestone. Dete

- Page 217 and 218:

59. E. G. Perkins and C. Smick. Oct

- Page 219 and 220:

97. Association of Official Analyti

- Page 221 and 222:

136. J. J. Myer and A. Kukis. Elect

- Page 223 and 224:

7 Chemistry of Frying Oils KATHLEEN

- Page 225 and 226:

Table 1 Effects of Physical and Che

- Page 227 and 228:

Figure 3 Oxidation reactions in fry

- Page 229 and 230:

or intermittent frying, oil filtrat

- Page 231 and 232:

for the ultimate criteria to evalua

- Page 233 and 234:

triacylglycerol polymers, and triac

- Page 235 and 236:

100 compounds identified in hydroge

- Page 237 and 238:

5. J. Pokorny. Flavor chemistry of

- Page 239 and 240:

50. Anonymous. Recommendations of t

- Page 241 and 242:

8 Recovery, Refining, Converting, a

- Page 243 and 244:

Figure 1 Depiction of hard screw pr

- Page 245 and 246:

Figure 2 Depiction of prepress solv

- Page 247 and 248:

Seed containing more than the criti

- Page 249 and 250:

Figure 5 Steps in processing soybea

- Page 251 and 252:

specification of 50% protein is met

- Page 253 and 254:

tent of prepress cake is 15-18%, an

- Page 255 and 256:

in successive passes through the be

- Page 257 and 258:

Figure 10 Additional commonly used

- Page 259 and 260:

that follow the DT. Drying at norma

- Page 261 and 262:

B. Extraction of Oil-Bearing Fruits

- Page 263 and 264:

1. Wet Rendering Wet rendering is t

- Page 265 and 266:

Figure 15 Process flow sheet for de

- Page 267 and 268:

Table 2 Properties of Some Crude an

- Page 269 and 270:

Figure 16 Process flow sheet for al

- Page 271 and 272:

Figure 17 Process flow sheet for va

- Page 273 and 274:

for problematic high wax contents (

- Page 275 and 276:

Figure 19 Oil processing facilities

- Page 277 and 278:

Figure 20 Depiction of physical ref

- Page 279 and 280:

4-7�C, and then to tanks with slo

- Page 281 and 282:

Figure 21 Hydrogenation reaction me

- Page 283 and 284:

ond, which may form in its original

- Page 285 and 286:

Figure 24 Plasticization of margari

- Page 287 and 288:

Figure 25 Equipment used in expande

- Page 289 and 290:

selectivity, others claim success i

- Page 291 and 292:

48. E. J. Campbell. Sunflower oil.

- Page 293 and 294:

9 Crystallization and Polymorphism

- Page 295 and 296:

Generally, it is accepted that both

- Page 297 and 298:

Figure 2 A point lattice. (Adapted

- Page 299 and 300:

structure.... The term ‘fat’ us

- Page 301 and 302:

Figure 6 Schematic representation o

- Page 303 and 304:

Figure 8 Polymorphic transitions of

- Page 305 and 306:

where A = B = C and all are saturat

- Page 307 and 308:

LMF was found to facilitate the tra

- Page 309 and 310:

Table 3 Nomenclature and Melting Po

- Page 311 and 312:

Other mixed-fat systems have been s

- Page 313 and 314:

Figure 12 Proposed intermediate str

- Page 315 and 316:

17. K. Larsson. The crystal structu

- Page 317 and 318:

59. G. G. Jewell. Vegetable fats. I

- Page 319 and 320:

10 Chemical Interesterification of

- Page 321 and 322:

however, since monoacylglycerols an

- Page 323 and 324:

D. The ‘‘Real’’ Catalyst Th

- Page 325 and 326:

Figure 3 Proposed reaction mechanis

- Page 327 and 328:

Figure 5 Kinetics of interesterific

- Page 329 and 330:

Table 1 Theoretical Triacylglycerol

- Page 331 and 332:

Cast et al. [55] demonstrated the r

- Page 333 and 334:

Solid: Liquid: SSS, 33.3% OOO, 8.3%

- Page 335 and 336:

Figure 11 Changes in the fatty acid

- Page 337 and 338:

fication and blending on butterfat-

- Page 339 and 340:

influence of interesterification on

- Page 341 and 342:

B. Margarines In the manufacture of

- Page 343 and 344:

Figure 16 Proportion of soild fat o

- Page 345 and 346:

Tautorus and McCurdy [102] demonstr

- Page 347 and 348:

ACKNOWLEDGMENTS The authors acknowl

- Page 349 and 350:

54. A. Kuksis, M. J. McCarthy, and

- Page 351 and 352:

101. S. Zalewski and A. M. Gaddis.

- Page 353 and 354:

11 Lipid Oxidation of Edible Oil DA

- Page 355 and 356:

Figure 1 Molecular orbital of tripl

- Page 357 and 358:

Figure 3 Singlet oxygen formation b

- Page 359 and 360:

tween substrate and triplet oxygen

- Page 361 and 362:

Figure 8 Conjugated and nonconjugat

- Page 363 and 364:

Figure 11 Conjugated hydroperoxide

- Page 365 and 366:

etween the oxygen and the oxygen of

- Page 367 and 368:

cadienal, trans,trans-2,4-decadiena

- Page 369 and 370:

Figure 14 Mechanism for the formati

- Page 371 and 372:

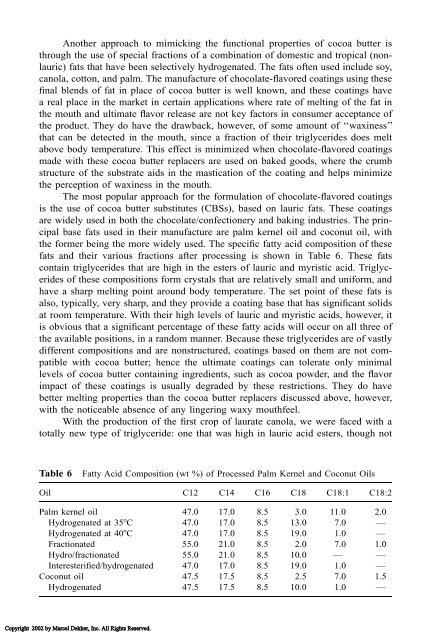

Copyright 2002 by Marcel Dekker, In

- Page 373 and 374:

Figure 18 Formation and reactions o

- Page 375 and 376:

Figure 19 Effect of 0, 0.25, 0.5, a

- Page 377 and 378:

Figure 21 Singlet oxygen quenching

- Page 379 and 380:

10. E. N. Frankel. Chemistry of aut

- Page 381 and 382:

52. A. L. Callison. Singlet oxygen

- Page 383 and 384:

12 Lipid Oxidation of Muscle Foods

- Page 385 and 386:

A. Initiation The direct reaction o

- Page 387 and 388:

undles), and endomysia (sheaths of

- Page 389 and 390:

sosomes, etc. A comparison of the l

- Page 391 and 392:

dative stability, comparisons betwe

- Page 393 and 394:

5. Hydrolysis of Lipids and Associa

- Page 395 and 396:

of iron from the heme pocket by coo

- Page 397 and 398:

Membrane systems that reduce iron c

- Page 399 and 400:

phases of storage [51,187,188]. In

- Page 401 and 402:

4. Glutathione While the traditiona

- Page 403 and 404:

G. Mathematical Modeling The pathwa

- Page 405 and 406:

with this chemical, treated salmon

- Page 407 and 408:

multicomponent alternatives [304,30

- Page 409 and 410:

and its extent was related to inten

- Page 411 and 412:

esponded similarly to vacuum packag

- Page 413 and 414:

31. M. L. Greaser, R. G. Cassens, W

- Page 415 and 416:

72. J. S. Elmore, D. S. Mottram, M.

- Page 417 and 418:

112. J. Kanner, H. Mendel, and P. B

- Page 419 and 420:

154. M. B. Korycka-Dahl and T. Rich

- Page 421 and 422:

193. P. Akhtar, J. I. Gray, T. H. C

- Page 423 and 424:

230. B. Bjerkeng and G. Johnsen. Fr

- Page 425 and 426:

271. C.-J. Huang, and M.-L. Fwu. De

- Page 427 and 428:

313. M. G. Mast and J. H. MacNeil.

- Page 429 and 430:

353. H. A. Ghanbari, W. B. Wheeler,

- Page 431 and 432:

13 Fatty Acid Oxidation in Plant Ti

- Page 433 and 434:

1. Fatty Acid Activation Prior to d

- Page 435 and 436:

L.) leaf peroxisomes exhibits highe

- Page 437 and 438:

Figure 2 The glyoxylate cycle in gl

- Page 439 and 440:

C. �-Oxidation of Specific Fatty

- Page 441 and 442:

cotyledons and partially purified.

- Page 443 and 444:

Catabolism of heptanoyl CoA as well

- Page 445 and 446:

Figure 6 Peroxisome catabolism of m

- Page 447 and 448:

onstrated that �-oxidations requi

- Page 449 and 450:

that the member of the enzyme famil

- Page 451 and 452:

Plant oxylipin pathway, also named

- Page 453 and 454:

Figure 9 Proposed scheme for lipoxy

- Page 455 and 456:

oleic acid. These results suggest t

- Page 457 and 458:

of the seed pod reversed senescnece

- Page 459 and 460:

Figure 11 ‘‘Heterolytic’’-t

- Page 461 and 462:

Since 1971, when this physiologic r

- Page 463 and 464:

Table 1 Physiological Effects of Ja

- Page 465 and 466:

erides, although PUFAs in both form

- Page 467 and 468:

9-hydroperoxides and did not attack

- Page 469 and 470:

aerial parts of plants, constitutes

- Page 471 and 472:

32. J. B. Ohlrogge and V. S. Eccles

- Page 473 and 474:

74. L. J. Morris. The mechanism of

- Page 475 and 476:

115. B. A. Vick. Oxygenated fatty a

- Page 477 and 478:

153. T. K. Peterman and J. N. Siedo

- Page 479 and 480:

193. B. A. Stelmach, A. Müller, P.

- Page 481 and 482:

230. M. Hamberg, C. A. Herman, and

- Page 483 and 484:

14 Methods for Measuring Oxidative

- Page 485 and 486:

ated fatty acids during oxidation (

- Page 487 and 488:

Several other chemical methods have

- Page 489 and 490:

Figure 3 Relationship between perox

- Page 491 and 492:

distillate. In case of the distilla

- Page 493 and 494:

and ketones. This ion is formed fro

- Page 495 and 496:

(Fig. 9), foaming, color, viscosity

- Page 497 and 498:

Yen and Duh [69] and Chen and Ho [7

- Page 499 and 500:

Figure 10 1 H Nuclear magnetic reso

- Page 501 and 502:

to Marquez-Ruiz et al. [93], who us

- Page 503 and 504:

35. F. Shahidi, J. Yun, L.J. Rubin,

- Page 505 and 506:

77. H. Saito and K. Nakamura. Appli

- Page 507 and 508:

15 Antioxidants DAVID W. REISCHE Th

- Page 509 and 510:

Hydroperoxide degradation leads to

- Page 511 and 512:

e cyclical, with regeneration of th

- Page 513 and 514:

A. Synthetic Antioxidants Synthetic

- Page 515 and 516:

Propyl gallate (PG) 212.20 White cr

- Page 517 and 518:

4. 6-Ethoxy-1,2-dihydro-2,2,4-trime

- Page 519 and 520:

Figure 3 Structures of tocopherols

- Page 521 and 522:

Figure 4 Structures of ascorbic aci

- Page 523 and 524:

4. Enzymatic Antioxidants Glucose o

- Page 525 and 526:

would be imprudent to discount any

- Page 527 and 528:

droxycoumarin (scopoletin), and hyd

- Page 529 and 530:

Figure 7 Structures of sesame antio

- Page 531 and 532:

8. G. Minotti. Sources and role of

- Page 533 and 534:

50. K. Shimada, H. Muta, Y. Nakamur

- Page 535 and 536:

16 Antioxidant Mechanisms ERIC A. D

- Page 537 and 538:

For instance, the hydrogen of the h

- Page 539 and 540:

Figure 2 Mechanism by which one phe

- Page 541 and 542:

Figure 4 Formation of �-tocophero

- Page 543 and 544:

Figure 6 Formation of an epoxyquino

- Page 545 and 546:

gallate. The antioxidant mechanism

- Page 547 and 548:

Figure 8 Products formed from the o

- Page 549 and 550:

in food systems, transition metals

- Page 551 and 552:

An intersystem energy transfer occu

- Page 553 and 554:

V. ALTERATIONS IN LIPID OXIDATION B

- Page 555 and 556:

VII. ANTIOXIDANT INTERACTIONS Biolo

- Page 557 and 558:

26. J. Kanner, J. B. German, and J.

- Page 559 and 560:

68. J. Kanner, F. Sofer, S. Harel,

- Page 561 and 562:

17 Fats and Oils in Human Health DA

- Page 563 and 564:

Table 1 Classification of LDL Parti

- Page 565 and 566:

stearic) had been incorporated by i

- Page 567 and 568:

studies contains equal amounts (40-

- Page 569 and 570:

Table 5 Influence of 25% Caloric Re

- Page 571 and 572:

26. L. D. Cowan, D. L. O’Connell,

- Page 573 and 574:

fatty acid margarine on serum lipid

- Page 575 and 576:

nutrition examination survey. I. Ep

- Page 577 and 578:

18 Unsaturated Fatty Acids STEVEN M

- Page 579 and 580:

Figure 1 A generalized scheme for h

- Page 581 and 582:

Plant fatty acids provide a seminal

- Page 583 and 584:

plants [27]. However, the requireme

- Page 585 and 586:

The reciprocal response of the �6

- Page 587 and 588:

fatty acids and a dynamic system fo

- Page 589 and 590:

production of commercially viable o

- Page 591 and 592:

acids synthesized de novo, primaril

- Page 593 and 594:

Figure 4 The cis and trans configur

- Page 595 and 596:

VI. SYNTHESIS AND ABUNDANCE OF PUFA

- Page 597 and 598:

of eicosanoids. It is present in al

- Page 599 and 600:

usual NMIFA structures with potenti

- Page 601 and 602:

10. S. P. Baykousheva, D. L. Luthri

- Page 603 and 604:

47. M. J. T. Alaniz, I. N. T. d. Go

- Page 605 and 606:

86. R. J. Henderson and D. R. Toche

- Page 607 and 608:

19 Dietary Fats, Eicosanoids, and t

- Page 609 and 610:

synthesize EPA from linolenic acid

- Page 611 and 612:

Figure 2 Immune responses as a func

- Page 613 and 614:

done predominantly in rodent specie

- Page 615 and 616:

guinea pigs showed increased immune

- Page 617 and 618:

of energy from fat. Feeding the low

- Page 619 and 620:

14. P. Purasiri, A. Murray, S. Rich

- Page 621 and 622:

20 Dietary Fats and Coronary Heart

- Page 623 and 624:

(HDLs). Each class has its own char

- Page 625 and 626:

70% of the total amount of choleste

- Page 627 and 628:

McGandy and coworkers [8] have care

- Page 629 and 630:

Figure 4 Effects of myristic and pa

- Page 631 and 632:

3. Polyunsaturated Fatty Acids Poly

- Page 633 and 634:

Figure 8 Effects of a mixture of sa

- Page 635 and 636:

chemoattractant protein-1 (MCP-1),

- Page 637 and 638:

Figure 11 In vitro LDL oxidation. F

- Page 639 and 640:

Table 4 Fatty Acid Composition of a

- Page 641 and 642:

Figure 12 Processes involved in thr

- Page 643 and 644:

as compared with a diet rich in but

- Page 645 and 646:

from cardiovascular disease [73,74]

- Page 647 and 648:

Figure 16 Schematic representation

- Page 649 and 650:

aggregation tendency induced by som

- Page 651 and 652:

35. D. R. Janero. Malondialdehyde a

- Page 653 and 654:

68. B. J. Burrl, R. M. Dougherty, D

- Page 655 and 656:

21 Conjugated Linoleic Acids: Nutri

- Page 657 and 658:

method that works optimally in all

- Page 659 and 660:

adipose tissue contained two major

- Page 661 and 662:

providing rats with 0.5% and 1% CLA

- Page 663 and 664:

with the control group. Interesting

- Page 665 and 666:

feeding. These findings suggest tha

- Page 667 and 668:

In contrast to the antioxidative pr

- Page 669 and 670:

esponsible, at least in part, for t

- Page 671 and 672:

Yamasaki et al. studied CLA and ant

- Page 673 and 674:

17. J. K. G. Kramer, P. W. Parodi,

- Page 675 and 676:

55. C. Ip, S. F. Chin, J. A. Scimec

- Page 677 and 678:

90. J. S. Munday, K. G. Thompson, a

- Page 679 and 680:

126. J. Singh, R. Hamid, and B. S.

- Page 681 and 682:

22 Dietary Fats and Obesity DOROTHY

- Page 683 and 684:

For example, some have reported tha

- Page 685 and 686:

the fat component and the other hal

- Page 687 and 688:

shows that there is a negative corr

- Page 689 and 690:

C. Influence of Dietary Fat on Fatt

- Page 691 and 692:

Figure 1 Signal transduction cascad

- Page 693 and 694:

mals indicate that high-fat feeding

- Page 695 and 696:

processes. Numerous studies provide

- Page 697 and 698:

monier (252) suggested that in cert

- Page 699 and 700:

4. National Task Force on Obesity.

- Page 701 and 702:

46. F. Lucas, K. Ackroff, and A. Sc

- Page 703 and 704:

90. D. Mela. Sensory preference for

- Page 705 and 706:

133. D. R. Romsos and G. A. Leveill

- Page 707 and 708:

169. T. Ide, H. Kobayashi, L. Ashak

- Page 709 and 710:

207. A. B. Awad and E. A. Zepp. Alt

- Page 711 and 712:

246. Y. B. Kim, R. Nakajima, T. Mat

- Page 713 and 714:

23 Lipid-Based Synthetic Fat Substi

- Page 715 and 716:

operations, and in theory, can repl

- Page 717 and 718:

Table 3 Types of Lipid-Based Fat Su

- Page 719 and 720:

Figure 1 Structure of sucrose polye

- Page 721 and 722:

Figure 3 Synthetic scheme for olest

- Page 723 and 724:

Figure 5 Structure of sorbitol poly

- Page 725 and 726:

Figure 8 Structure of raffinose pol

- Page 727 and 728:

Figure 11 Structure of methyl galac

- Page 729 and 730:

Table 4 Some Properties of Sucrose

- Page 731 and 732:

Figure 15 Structure of trialkoxytri

- Page 733 and 734:

Figure 19 Structure of polysiloxane

- Page 735 and 736:

inversely related to the degree of

- Page 737 and 738:

Table 8 Some Nutritional Uses of No

- Page 739 and 740:

genetic assay in Chinese hamster ov

- Page 741 and 742:

IX. PERSPECTIVES With the approval

- Page 743 and 744:

30. L. Osipow, F. D. Snell, D. Marr

- Page 745 and 746:

72. K. W. Miller and P. H. Long. A

- Page 747 and 748:

24 Food Applications of Lipids FRAN

- Page 749 and 750:

Table 3 Typical Fatty Acid Composit

- Page 751 and 752:

are significant differences in oil

- Page 753 and 754:

Table 6 Production and Disappearanc

- Page 755 and 756:

and margarine should be pronounced

- Page 757 and 758:

Table 8 Approximate Fatty Acid Comp

- Page 759 and 760:

egions of the world. In addition to

- Page 761 and 762:

50-55% fat. Production figures for

- Page 763 and 764:

utter with up to 5% of another fat

- Page 765 and 766:

market with high overrun and good s

- Page 767 and 768:

11. D. Hettinga. Butter. In: Bailey

- Page 769 and 770:

25 Lipid Biotechnology KUMAR D. MUK

- Page 771 and 772:

Table 1 Lipid Content and Levels of

- Page 773 and 774:

as 80% lipids of which about 90% ar

- Page 775 and 776:

Table 6 Wax Esters Formed by Acinet

- Page 777 and 778:

Some other biosurfactants include e

- Page 779 and 780:

Figure 6 Microbial production of hy

- Page 781 and 782:

Figure 9 Microbial production of ke

- Page 783 and 784:

Figure 12 Microbial production of k

- Page 785 and 786:

Table 8 Specificity of Triacylglyce

- Page 787 and 788:

Figure 16 Lipase-catalyzed transest

- Page 789 and 790:

Figure 20 Preparation of structured

- Page 791 and 792:

Figure 24 Preparation of monoacylgl

- Page 793 and 794:

Fatty acid esters of polyols are us

- Page 795 and 796:

Figure 29 Specificity constants in

- Page 797 and 798:

Figure 31 Preparation of concentrat

- Page 799 and 800:

Figure 35 Enrichment of very long c

- Page 801 and 802:

B. Phospholipases Figure 38 shows t

- Page 803 and 804:

Lysophosphatidic acid has been prep

- Page 805 and 806:

Figure 41 Transesterification of ph

- Page 807 and 808:

Figure 46 Enzymatic production of h

- Page 809 and 810:

Figure 50 Hydration of linoleic aci

- Page 811 and 812:

Figure 51 Principle of enzymatic de

- Page 813 and 814:

13. E. Molina Grima, J. A. Sánchez

- Page 815 and 816:

53. M. Powalla, S. Lang, and V. Wra

- Page 817 and 818:

96. R. Schuch and K. D. Mukherjee.

- Page 819 and 820:

138. K. D. Mukherjee and I. Kiewitt

- Page 821 and 822:

179. U. T. Bornscheuer, H. Stamatis

- Page 823 and 824:

222. H. Stamatis, V. Sereti, and F.

- Page 825 and 826:

265. S. R. Moore and G. P. McNeill.

- Page 827 and 828:

303. C. Virto, I. Svensson, and P.

- Page 829 and 830:

343. E. Blee and F. Schuber. Regio-

- Page 831 and 832:

26 Microbial Lipases JOHN D. WEETE

- Page 833 and 834:

ation. Fungal lipases typically exi

- Page 835 and 836:

of buffer A containing 1 M ammonium

- Page 837 and 838:

without shaking for 30 minutes, whe

- Page 839 and 840:

the C domain of the protein through

- Page 841 and 842:

Figure 2 (Continued) Figure 3 Schem

- Page 843 and 844:

on the substrate and presence or ab

- Page 845 and 846:

Table 3 Selectivities of Multiple E

- Page 847 and 848:

lanuginosa, C. antarctica B, Rhizop

- Page 849 and 850:

10. C. T. Hou and T. M. Johnston. S

- Page 851 and 852:

53. C. C. Akoh. Enzymatic synthesis

- Page 853 and 854:

94. D. M. Lawson, A. M. Brzozowski,

- Page 855 and 856:

135. B. K. Yang and J. P. Chen. Gel

- Page 857 and 858:

27 Enzymatic Interesterification WE

- Page 859 and 860:

esterification of butterfat at 40

- Page 861 and 862:

also found to decrease the crystall

- Page 863 and 864:

T c than animal fats. The T c for v

- Page 865 and 866:

in the oxyanion hole is the amino a

- Page 867 and 868:

of the interface as a measure of su

- Page 869 and 870:

Figure 11 Catalytic mechanism for l

- Page 871 and 872:

Figure 13 Triacylglycerol products

- Page 873 and 874:

imization of interesterification, a

- Page 875 and 876:

supports include high losses of act

- Page 877 and 878:

is a thin layer located directly ne

- Page 879 and 880:

volume per year. The volumetric act

- Page 881 and 882:

and removal of reactants and produc

- Page 883 and 884:

vinyl chloride. In a membrane such

- Page 885 and 886:

of the enzyme. Animal and plant lip

- Page 887 and 888:

esters as surface active agents dur

- Page 889 and 890:

14. P. Kalo, H. Huotari, and M. Ant

- Page 891 and 892:

57. F. Pabai, S. Kermasha, and A. M

- Page 893 and 894:

94. J. Kurashige. Enzymatic convers

- Page 895 and 896:

28 Structured Lipids CASIMIR C. AKO

- Page 897 and 898:

Figure 2 Structure of a physical mi

- Page 899 and 900:

2. Medium Chain Fatty Acids and Tri

- Page 901 and 902:

Figure 4 Pathway for eicosanoid bio

- Page 903 and 904:

leukotrienes (hydroxy fatty acids a

- Page 905 and 906:

Figure 7 Structure of Benefat (bran

- Page 907 and 908:

cause of the huge capital investmen

- Page 909 and 910:

Figure 8 Reaction scheme showing ac

- Page 911 and 912:

alters the native conformation of t

- Page 913 and 914:

Table 6 Advantages of Enzymatic App

- Page 915 and 916:

Figure 13 Stereochemical configurat

- Page 917 and 918:

IV. NUTRITIONAL AND MEDICAL APPLICA

- Page 919 and 920:

Table 9 Factors That Affect Outlook

- Page 921 and 922:

27. G. O. Burr and M. D. Burr. A ne

- Page 923 and 924:

69. M. Reslow, P. Aldercreutz, and

- Page 925 and 926:

113. C. J. Gollaher, E. S. Swenson,

- Page 927 and 928:

29 Biosynthesis of Fatty Acids and

- Page 929 and 930:

olive (Olea europea), and avocado (

- Page 931 and 932:

Table 2 (Continued) Fatty acid a Sp

- Page 933 and 934:

2. Basic Features The functional un

- Page 935 and 936:

Hydroxy-Acyl ACP dehydrase (Crotony

- Page 937 and 938:

Figure 1 Steps of fatty acid biosyn

- Page 939 and 940:

The three KAS isoforms are assigned

- Page 941 and 942:

chain length acyl-ACP residues, and

- Page 943 and 944:

10-carbon and 14- to 16-carbon acyl

- Page 945 and 946:

In developing castor seed, BC and A

- Page 947 and 948:

(viz., seed, fruit) genes, and this

- Page 949 and 950:

Figure 4 Fatty acid modification re

- Page 951 and 952:

12-MO, the cDNA for the enzyme has

- Page 953 and 954:

Table 5 Enzyme Activities Involved

- Page 955 and 956: of reactivity is also supported by

- Page 957 and 958: tems, PTAP is a likely candidate fo

- Page 959 and 960: ifying 18:1 �9 and deacylating 18

- Page 961 and 962: oils (rich in 18:3 �6,9,12), and

- Page 963 and 964: eticulum subpopulations also finds

- Page 965 and 966: CPT (DAG ↔ PC) Extensive involvem

- Page 967 and 968: available (cf. Sec. V.C.4 and Ref.

- Page 969 and 970: erol backbone of triacylglycerols c

- Page 971 and 972: 14. E. Heinz. Biosynthesis of polyu

- Page 973 and 974: 56. R. C. Clough, A. L. Matthis, S.

- Page 975 and 976: 91. R. J. Heath and C. O. Rock. Eno

- Page 977 and 978: 124. R. Schuch, F. M. Brück, M. Br

- Page 979 and 980: Kader and P. Mazliak, eds.). Kluwer

- Page 981 and 982: 197. Y. Cao, K. Oo, and A. H. C. Hu

- Page 983 and 984: 241. M. C. Dobarganes, G. Márquez-

- Page 985 and 986: 30 Genetic Engineering of Crops Tha

- Page 987 and 988: existing genes in the host plant ge

- Page 989 and 990: It becomes the plant breeder’s jo

- Page 991 and 992: previously mentioned low-linolenic

- Page 993 and 994: develop and apply methods, evaluate

- Page 995 and 996: enzyme with high activity for placi

- Page 997 and 998: activity in the oil palm mesocarp s

- Page 999 and 1000: Figure 4 Commercial applications of

- Page 1001 and 1002: and mildness. Because the perennial

- Page 1003 and 1004: In the context of developing increa

- Page 1005: occurs esterified at the sn-2 posit

- Page 1009 and 1010: systems. Key to assessing the oppor

- Page 1011 and 1012: property encouraged us to look for

- Page 1013 and 1014: mercial lauric fats based on both P