Salt Lake City: Livability in the 21st Century

A full-color, photography book showcasing Salt Lake City, Utah, paired with the histories of companies, institutions, and organizations that have made the city great.

A full-color, photography book showcasing Salt Lake City, Utah, paired with the histories of companies, institutions, and organizations that have made the city great.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

US MAGNESIUM, LLC<br />

❖<br />

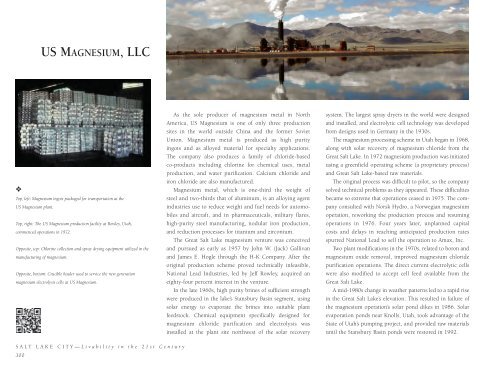

Top, left: Magnesium <strong>in</strong>gots packaged for transportation at <strong>the</strong><br />

US Magnesium plant.<br />

Top, right: The US Magnesium production facility at Rowley, Utah,<br />

commenced operations <strong>in</strong> 1972.<br />

Opposite, top: Chlor<strong>in</strong>e collection and spray dry<strong>in</strong>g equipment utilized <strong>in</strong> <strong>the</strong><br />

manufactur<strong>in</strong>g of magnesium.<br />

Opposite, bottom: Crucible hauler used to service <strong>the</strong> new generation<br />

magnesium electrolysis cells at US Magnesium.<br />

As <strong>the</strong> sole producer of magnesium metal <strong>in</strong> North<br />

America, US Magnesium is one of only three production<br />

sites <strong>in</strong> <strong>the</strong> world outside Ch<strong>in</strong>a and <strong>the</strong> former Soviet<br />

Union. Magnesium metal is produced as high purity<br />

<strong>in</strong>gots and as alloyed material for specialty applications.<br />

The company also produces a family of chloride-based<br />

co-products <strong>in</strong>clud<strong>in</strong>g chlor<strong>in</strong>e for chemical uses, metal<br />

production, and water purification. Calcium chloride and<br />

iron chloride are also manufactured.<br />

Magnesium metal, which is one-third <strong>the</strong> weight of<br />

steel and two-thirds that of alum<strong>in</strong>um, is an alloy<strong>in</strong>g agent<br />

<strong>in</strong>dustries use to reduce weight and fuel needs for automobiles<br />

and aircraft, and <strong>in</strong> pharmaceuticals, military flares,<br />

high-purity steel manufactur<strong>in</strong>g, nodular iron production,<br />

and reduction processes for titanium and zirconium.<br />

The Great <strong>Salt</strong> <strong>Lake</strong> magnesium venture was conceived<br />

and pursued as early as 1957 by John W. (Jack) Gallivan<br />

and James E. Hogle through <strong>the</strong> H-K Company. After <strong>the</strong><br />

orig<strong>in</strong>al production scheme proved technically <strong>in</strong>feasible,<br />

National Lead Industries, led by Jeff Rowley, acquired an<br />

eighty-four percent <strong>in</strong>terest <strong>in</strong> <strong>the</strong> venture.<br />

In <strong>the</strong> late 1960s, high purity br<strong>in</strong>es of sufficient strength<br />

were produced <strong>in</strong> <strong>the</strong> lake’s Stansbury Bas<strong>in</strong> segment, us<strong>in</strong>g<br />

solar energy to evaporate <strong>the</strong> br<strong>in</strong>es <strong>in</strong>to suitable plant<br />

feedstock. Chemical equipment specifically designed for<br />

magnesium chloride purification and electrolysis was<br />

<strong>in</strong>stalled at <strong>the</strong> plant site northwest of <strong>the</strong> solar recovery<br />

system. The largest spray dryers <strong>in</strong> <strong>the</strong> world were designed<br />

and <strong>in</strong>stalled, and electrolytic cell technology was developed<br />

from designs used <strong>in</strong> Germany <strong>in</strong> <strong>the</strong> 1930s.<br />

The magnesium process<strong>in</strong>g scheme <strong>in</strong> Utah began <strong>in</strong> 1968,<br />

along with solar recovery of magnesium chloride from <strong>the</strong><br />

Great <strong>Salt</strong> <strong>Lake</strong>. In 1972 magnesium production was <strong>in</strong>itiated<br />

us<strong>in</strong>g a greenfield operat<strong>in</strong>g scheme (a proprietary process)<br />

and Great <strong>Salt</strong> <strong>Lake</strong>-based raw materials.<br />

The orig<strong>in</strong>al process was difficult to pilot, so <strong>the</strong> company<br />

solved technical problems as <strong>the</strong>y appeared. These difficulties<br />

became so extreme that operations ceased <strong>in</strong> 1975. The company<br />

consulted with Norsk Hydro, a Norwegian magnesium<br />

operation, rework<strong>in</strong>g <strong>the</strong> production process and resum<strong>in</strong>g<br />

operations <strong>in</strong> 1976. Four years later, unplanned capital<br />

costs and delays <strong>in</strong> reach<strong>in</strong>g anticipated production rates<br />

spurred National Lead to sell <strong>the</strong> operation to Amax, Inc.<br />

Two plant modifications <strong>in</strong> <strong>the</strong> 1970s, related to boron and<br />

magnesium oxide removal, improved magnesium chloride<br />

purification operations. The direct current electrolytic cells<br />

were also modified to accept cell feed available from <strong>the</strong><br />

Great <strong>Salt</strong> <strong>Lake</strong>.<br />

A mid-1980s change <strong>in</strong> wea<strong>the</strong>r patterns led to a rapid rise<br />

<strong>in</strong> <strong>the</strong> Great <strong>Salt</strong> <strong>Lake</strong>’s elevation. This resulted <strong>in</strong> failure of<br />

<strong>the</strong> magnesium operation’s solar pond dikes <strong>in</strong> 1986. Solar<br />

evaporation ponds near Knolls, Utah, took advantage of <strong>the</strong><br />

State of Utah’s pump<strong>in</strong>g project, and provided raw materials<br />

until <strong>the</strong> Stansbury Bas<strong>in</strong> ponds were restored <strong>in</strong> 1992.<br />

S A L T L A K E C I T Y — L i v a b i l i t y i n t h e 2 1 s t C e n t u r y<br />

300