- Page 1 and 2:

User Guide Volume 3 MANUFACTURING P

- Page 3 and 4:

Contents ABOUT THIS GUIDE . . . . .

- Page 5 and 6:

CONTENTS V Defining Processes . . .

- Page 7 and 8:

CONTENTS VII Lead Time Calculations

- Page 9 and 10:

CONTENTS IX Common Transaction Data

- Page 11 and 12:

CONTENTS XI Maintaining Master Sche

- Page 13 and 14:

What Is in This Guide? 2 Windows Ke

- Page 15 and 16:

QAD Web Site or MFG/PRO users with

- Page 17 and 18:

Navigation Commands User Menu F6 Ct

- Page 19 and 20:

CHAPTER 1 Introduction to Manufactu

- Page 21 and 22:

Formula/Process The Formula/Process

- Page 23 and 24:

CHAPTER 2 Product Structures This c

- Page 25 and 26:

If a single company manufactures th

- Page 27 and 28:

Alternate Structures/Formulas An it

- Page 29 and 30:

Setting Up a Product Structure Defi

- Page 31 and 32:

equired, consider changing the comp

- Page 33 and 34:

Relationship with Configured Produc

- Page 35 and 36:

Assembly or Component Lead Time Sun

- Page 37 and 38:

CHAPTER 3 Routings/Work Centers Thi

- Page 39 and 40:

Some of these capabilities are espe

- Page 41 and 42:

Account Type Use Burden Usage Var E

- Page 43 and 44:

Machines. Enter the number of machi

- Page 45 and 46:

Yield %. Enter the order percentage

- Page 47 and 48:

Planning Maintenance (1.4.7) or Ite

- Page 49 and 50:

Work Center Routing Standards Somet

- Page 51 and 52:

If you examine this formula, severa

- Page 53 and 54:

Set the work center labor and burde

- Page 55 and 56:

CHAPTER 4 Formula/Process The Formu

- Page 57 and 58:

The Formula/Process module works in

- Page 59 and 60:

BOM/Formula as an alternate using A

- Page 61 and 62:

Use this frame to specify which scr

- Page 63 and 64:

CHAPTER 5 Co-products/ By-products

- Page 65 and 66:

Overview A base process is a manufa

- Page 67 and 68:

More About Co-products and By-produ

- Page 69 and 70:

Setting Up Mix Variance Accounts If

- Page 71 and 72:

Order Policy. Enter POQ or FOQ. MRP

- Page 73 and 74:

Qty Type. Enter B for batch, P for

- Page 75 and 76:

To set up a structure for a recycla

- Page 77 and 78:

Only a base process can have altern

- Page 79 and 80:

Although prune juice is a significa

- Page 81 and 82:

Rolling Up Costs Roll up lower-leve

- Page 83 and 84:

Allocation by Price The percentage

- Page 85 and 86:

• Closed. Co-product costs are re

- Page 87 and 88:

ecord for its base process. This de

- Page 89 and 90:

When a planned purchase order is ap

- Page 91 and 92:

Accessing and Modifying Joint Order

- Page 93 and 94:

Mix Variance Acct. Enter the accoun

- Page 95 and 96:

Backflush Calculation Methods Speci

- Page 97 and 98:

Receiving Unplanned Items Use Unpla

- Page 99 and 100:

(Supplier) Schedule Update from MRP

- Page 101 and 102:

CHAPTER 6 Work Orders The Work Orde

- Page 103 and 104:

• Schedule operations with Capaci

- Page 105 and 106:

Creating Work Orders Work orders ar

- Page 107 and 108:

Table 6.2 lists work order type cod

- Page 109 and 110:

Scheduled Work Orders Scheduled wor

- Page 111 and 112:

Planned Bills Bill created Routings

- Page 113 and 114:

Released A released order is like a

- Page 115 and 116:

• The release date is the date wh

- Page 117 and 118:

the average order quantity, the les

- Page 119 and 120:

Modifying Work Order Routings Use W

- Page 121 and 122:

Creating Picklists After you releas

- Page 123 and 124:

Issues are not restricted to what t

- Page 125 and 126:

Subcontract Operations Work orders

- Page 127 and 128:

Receiving and Backflushing When you

- Page 129 and 130:

Example Ten phantoms are in stock.

- Page 131 and 132:

Generating Reports Many of the Work

- Page 133 and 134:

Closing Work Orders To close a work

- Page 135 and 136:

6 Print Work Order WIP Cost Report

- Page 137 and 138:

CHAPTER 7 Shop Floor Control The Sh

- Page 139 and 140:

You can calculate employee efficien

- Page 141 and 142:

Times You can enter setup times, ru

- Page 143 and 144:

You can review recorded downtime us

- Page 145 and 146:

Downtime Review recorded downtime b

- Page 147 and 148:

CHAPTER 8 Advanced Repetitive Repet

- Page 149 and 150:

• Batches can overlap and visibil

- Page 151 and 152:

Setting Up Advanced Repetitive Repe

- Page 153 and 154:

• PO Shipper Receipt (5.5.5.5) Wh

- Page 155 and 156:

production lines. To set up multipl

- Page 157 and 158:

is 700 units per shift. If a second

- Page 159 and 160:

Milestone and Non-Milestone Operati

- Page 161 and 162:

In the first, there is a primary st

- Page 163 and 164:

Whenever you create or modify a seq

- Page 165 and 166:

Creating Repetitive Schedules A rep

- Page 167 and 168:

The schedule explodes automatically

- Page 169 and 170:

The Net Available is the material a

- Page 171 and 172:

Transfer the Inventory Use Repetiti

- Page 173 and 174:

• Cumulative Order Close (18.22.1

- Page 175 and 176:

Processing Steps Cumulative Order C

- Page 177 and 178:

Common Transaction Data All repetit

- Page 179 and 180:

Rate Variance All transactions cons

- Page 181 and 182:

Repetitive Transaction Programs The

- Page 183 and 184:

The component backflush logic looks

- Page 185 and 186:

Scrap Transaction Use Backflush Tra

- Page 187 and 188:

cumulative order. The amounts to po

- Page 189 and 190:

Generating Repetitive Reports Table

- Page 191 and 192:

Using Scheduled Orders You can hand

- Page 193 and 194:

If there is no WIP item number ente

- Page 195 and 196:

CHAPTER 9 Repetitive The Repetitive

- Page 197 and 198:

Defining Control File Settings Sett

- Page 199 and 200:

Operation Reporting The reporting o

- Page 201 and 202:

• If the remainder is positive, t

- Page 203 and 204:

CHAPTER 10 Quality Management MFG/P

- Page 205 and 206: Setting Up Quality Management Befor

- Page 207 and 208: A comparative symbol (, =) and a nu

- Page 209 and 210: Defining Sampling Patterns Define s

- Page 211 and 212: Type. Specify the type of testing t

- Page 213 and 214: Conducting Process Inspections When

- Page 215 and 216: Use inventory sampling patterns to

- Page 217 and 218: CHAPTER 11 Forecasting/Master Sched

- Page 219 and 220: 6 Load the detail forecast records

- Page 221 and 222: FORECASTING/MASTER SCHEDULE PLANNIN

- Page 223 and 224: Forecast Methods FORECASTING/MASTER

- Page 225 and 226: FORECASTING/MASTER SCHEDULE PLANNIN

- Page 227 and 228: FORECASTING/MASTER SCHEDULE PLANNIN

- Page 229 and 230: Copying and Combining Forecasts FOR

- Page 231 and 232: FORECASTING/MASTER SCHEDULE PLANNIN

- Page 233 and 234: Generating Reports FORECASTING/MAST

- Page 235 and 236: FORECASTING/MASTER SCHEDULE PLANNIN

- Page 237 and 238: FORECASTING/MASTER SCHEDULE PLANNIN

- Page 239 and 240: FORECASTING/MASTER SCHEDULE PLANNIN

- Page 241 and 242: Fully Automatic Scheduling FORECAST

- Page 243 and 244: Available-to-Promise FORECASTING/MA

- Page 245 and 246: FORECASTING/MASTER SCHEDULE PLANNIN

- Page 247 and 248: FORECASTING/MASTER SCHEDULE PLANNIN

- Page 249 and 250: Generating Master Schedule Reports

- Page 251 and 252: CHAPTER 12 Material Requirements Pl

- Page 253 and 254: Sources of Demand MRP considers the

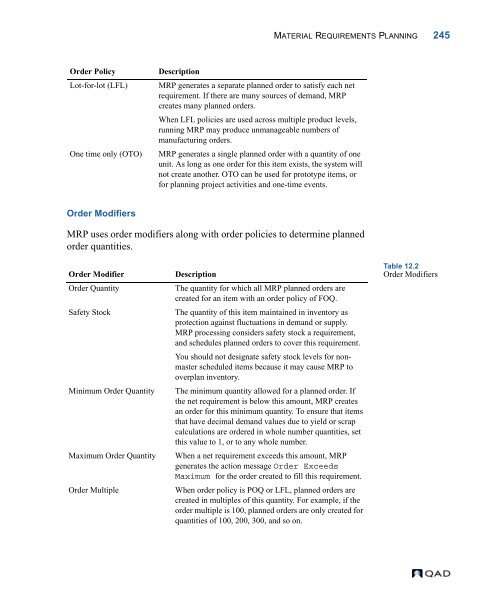

- Page 255: Item Planning Data MATERIAL REQUIRE

- Page 259 and 260: Time Fence MATERIAL REQUIREMENTS PL

- Page 261 and 262: Component Effective Dates MATERIAL

- Page 263 and 264: MRP Pegged Requirements MATERIAL RE

- Page 265 and 266: MATERIAL REQUIREMENTS PLANNING 253

- Page 267 and 268: Message Meaning Shipment Past Due I

- Page 269 and 270: CHAPTER 13 Capacity Requirements Pl

- Page 271 and 272: CAPACITY REQUIREMENTS PLANNING 259

- Page 273 and 274: Generating Load Reports You can gen

- Page 275 and 276: Adjusting Capacity and Load If a wo

- Page 277 and 278: Numerics 1.1.5 58 1.1.13 57 1.2.1 5

- Page 279 and 280: A Account Code Maintenance co-produ

- Page 281 and 282: defined 53 demand for 77 material r

- Page 283 and 284: Formula Maintenance 45 co-products/

- Page 285 and 286: MPS. See master production scheduli

- Page 287 and 288: epetitive 154, 183-189 completions

- Page 289 and 290: sources for MRP 241 System/Account