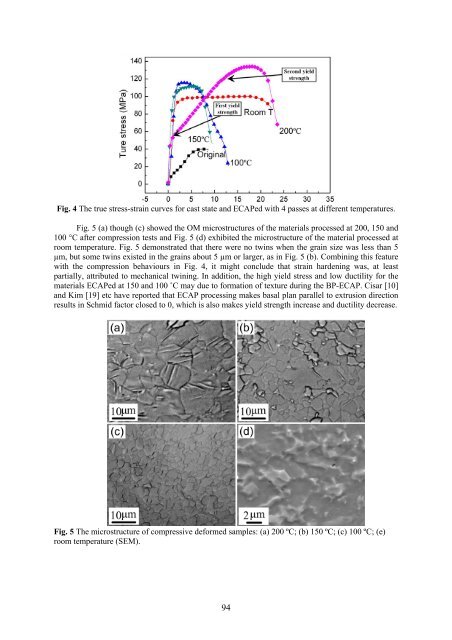

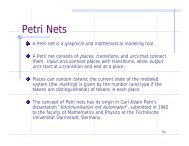

Fig. 4 The true stress-strain curves for cast state <strong>and</strong> ECAPed with 4 passes at different temperatures. Fig. 5 (a) though (c) showed the OM microstructures <strong>of</strong> the materials processed at 200, 150 <strong>and</strong> 100 °C after compression tests <strong>and</strong> Fig. 5 (d) exhibited the microstructure <strong>of</strong> the material processed at room temperature. Fig. 5 demonstrated that there were no twins when the grain size was less than 5 µm, but some twins existed in the grains about 5 µm or larger, as in Fig. 5 (b). Combining this feature with the compression behaviours in Fig. 4, it might conclude that strain hardening was, at least partially, attributed to mechanical twining. In addition, the high yield stress <strong>and</strong> low ductility for the materials ECAPed at 150 <strong>and</strong> 100 ˚C may due to formation <strong>of</strong> texture during the BP-ECAP. Cisar [10] <strong>and</strong> Kim [19] etc have reported that ECAP processing makes basal plan parallel to extrusion direction results in Schmid factor closed to 0, which is also makes yield strength increase <strong>and</strong> ductility decrease. Fig. 5 The microstructure <strong>of</strong> compressive deformed samples: (a) 200 ºC; (b) 150 ºC; (c) 100 ºC; (e) room temperature (SEM). 94

Conclusions (1) The large grains in the as-cast pure Mg were successfully refined into submicron sized grains using BP-ECAP at room temperature without cracks. (2) The compressive tests at room temperature showed that the yield strength might decrease as the grain size was reduced into submicron level. However, the ductility was significantly enhanced due to submicron grain size. (3) Strong strain hardening was attributed to large grain sizes, which was larger than 10 µm. Deformation twining, might contribute to the yield strength for the pure Mg materials having grains larger than 5 µm. References: [1] Y.T. Zhu, J.Y. Huang, J. Gubicza, T. Ungár, Y.M. Wang, E. Ma, R.Z. Valiev, J. Mater. Res. 18 (2003) 1908. [2] D. Jia, Y.M. Wang, K.T. Ramesh, E. Ma, Y.T. Zhu, R.Z. Valiev, Appl. Phys. Lett. 79 (2001) 611. [3] R. Valiev, Nature Mater. 3 (2004) 511. [4] Z. Horita, K. Ohashi, T. Fujita, K. Kaneko, T.G. Langdon, Adv. Mater. 17 (2005) 1599. [5] K. Matsubara, Y. Miyahara, Z. Horita, T. G. Langdon. Acta Mater. 51 (2003) 3073. [6] K. Xia , J. T. Wang, X. Wu, G. Chen, M. Gurvan. Mater. Sci. Eng. A 410-411 (2005)324. [7] C. Mallikarjuna, S. M. Shashidhara, U. S. Mallik. Mater. Design. 30 (2009) 1638. [8] P. L. Sun, P. W. Kao, C. P. Chang. Mater. Sci. Eng. A. 283 (2000) 82. [9] M. Furukawa, Y. Ma, Z. Horita, M. Nemoto, R. Z. Valiev, T. G. Langdon. Mater. Sci. Eng. A. 241 (1998) 122. [10] L. Cisar, Y. Yoshida, S. Kamado, Y. Kojima, F. Watanabe. Mater. Sci. Forum. 419-4 (2003) 249. [11] E. J. Kwak, C. H. Bok, M. H. Seo, H. S. Kim. Mater. Trans. 49 (2008) 1006. [12] X. Zhao, W. Fu, X. Yang, T. G. Langdon. Scripta Mater. 59 (2008) 542. [13] J. Koike, R. Ohyama. Acta Mater. 53 (2005) l963. [14] N. Ogawa, M. Shiomi, K. Osakada. Int J Mach Tool Manu. 42 (2002) 607. [15] W. M. Gan, M. Y. Zheng, H. Chang, B. Schwebke. J. Alloys. Comp. 470 (2009) 256. [16] A. Yamashita, Z. Horita, T. G. Langdon. Mater. Sci. Eng. A 300 (2001) 142. [17] K. Matsubara, Y. Miyahara, Z. Horita, T. G. Langdon. Metall. Mater. Trans. A 35 (2004) 1735. [18] S. Y. Chang, S. W. Lee, K. M. Kang, S. Kamado, Y. Kojima. Mater. Trans. 45 (2004) 488. [19] W. J. Kim, S. I. Hong, Y. S. Kim, S. H. Mind, H. T. Jeong, J. D. Lee. Acta Mater. 51 (2003) 3293. 95

- Page 2 and 3:

The 3 rd VACPS Research Workshop Pr

- Page 4 and 5:

Organizing Committee Victorian Asso

- Page 6 and 7:

Preface On the occasion of the publ

- Page 8 and 9:

Paper as a low-cost base material f

- Page 10 and 11:

Acknowledgements We gratefully ackn

- Page 13 and 14:

Career planning and Job Interview i

- Page 15 and 16:

The role of mitochondria in atrial

- Page 18 and 19:

Track-Before-Detect Procedures for

- Page 20 and 21:

3. Dynamic model for approaching ta

- Page 22 and 23:

⎧π0 if j = i and Cx ij k > δij

- Page 24 and 25:

k k k k ( ) p( p Ζ | X , B = ∏ z

- Page 26 and 27:

As illustrated in Fig.4, the struct

- Page 28 and 29:

( xˆ , m ˆ ) = argmax Γ ( x , m

- Page 30 and 31:

(a) (b) Fig. 7. mesh plot of the re

- Page 32 and 33:

Definition 2 The probability of tar

- Page 34 and 35:

Acknowledgments Xiaobo Deng would l

- Page 36 and 37:

speed, several methods can be utili

- Page 38 and 39:

Where u ′ , v′ ) is the point p

- Page 40 and 41:

ase on SIFT are also unsuitable to

- Page 42 and 43:

Demonstration and Performance Analy

- Page 45 and 46:

Effect of mini-tyrosl-tRNA syntheta

- Page 47 and 48:

2.1 Materials Sprague-Dauley(SD) ma

- Page 49 and 50:

Fig. 2. The representative photomic

- Page 51 and 52: mount/0.1mm 2 , as for mini-TrpRS g

- Page 53 and 54: 3.4.The mRNA expression of mini-Tyr

- Page 55 and 56: 9.Du XJ, Gao X, Ramsey D. Surgical

- Page 57 and 58: Distribution of three forms alpha-m

- Page 59 and 60: Materials and Methods Ethics All an

- Page 61 and 62: Fig.1 (A) Mass Spectrometry results

- Page 63 and 64: indicated that there is more des-α

- Page 65 and 66: Fig.6 (A) Mass Spectrometry results

- Page 67 and 68: transcription-polymerase chain reac

- Page 69 and 70: Investigation of the mechanism of t

- Page 71 and 72: Dual mode roll-up effect in a multi

- Page 73: Paper as a low-cost base material f

- Page 76 and 77: cloud computing offers a cost-effec

- Page 78 and 79: workflows. By comparing the generat

- Page 80 and 81: [10] E. Deelman, G. Singh, M. Livny

- Page 82 and 83: Web Page Prediction Based on Condit

- Page 84 and 85: A Multi-modal Gesture Recognition S

- Page 86: Searching for Fair Joint Gains in A

- Page 89 and 90: environments. However, challenges a

- Page 91 and 92: conclude that the hydrophobic PHB c

- Page 93 and 94: Figure 4. (a) Energy transfer model

- Page 95 and 96: 20 Intensity (/10 6 ) / a.u. 15 10

- Page 97 and 98: (22) (a) Cho, J.; Quinn, J. F.; Car

- Page 99 and 100: Grain refinement of pure magnesium

- Page 101: Fig. 3 The optical and SEM microstr

- Page 105 and 106: [22-25]. Sorting of normal and Babe

- Page 107 and 108: Figure 1. Г×Re[fCM] vs. frequency

- Page 109 and 110: Figure 3. The DEP spectrum of cylin

- Page 111 and 112: A B C Figure 5. The gradient of the

- Page 113 and 114: Figure 7. SEM image of damaged elec

- Page 115 and 116: Figure 9. Particle separation progr

- Page 117 and 118: The separation efficiency can be im

- Page 119 and 120: [37] A. Motayed, M. Q. He, A. V. Da

- Page 121 and 122: Fig. 1. The transverse and longitud

- Page 123 and 124: References: [1] Xiong Liu, Mark C.

- Page 125 and 126: new tissue[10]. Most of these human

- Page 127 and 128: 2.8 Viability and morphology study

- Page 129 and 130: Fig 3 and 4 SEM images of electrosp

- Page 131 and 132: studies have indicated that surface

- Page 133 and 134: Fig 10 Tensile Stress curve of elec

- Page 135 and 136: well as on a usual nanofibrous scaf

- Page 137 and 138: Uniform Coating of WO x on TiO 2 Na

- Page 140 and 141: Union as a Social Regulator of Mark

- Page 142 and 143: associated with a reinvention of in

- Page 144 and 145: enterprises…There obviously is no

- Page 146 and 147: Union assistants participate in org

- Page 148 and 149: [5] Deyo, Frederic C and Ağartan,

- Page 150 and 151: Organizational Capabilities • Lea

- Page 152 and 153:

Table 1. Correlations, Reliabilitie

- Page 154 and 155:

[18]. Jap, S. D. (1999). Pie-expans

- Page 156 and 157:

Early Childhood Education Matters:

- Page 158 and 159:

decisions on selection of child car

- Page 160 and 161:

Noble, K. (2007). Parent choice of

- Page 162:

An Exploration of Country of Origin

- Page 165 and 166:

Supercontinuum generation for fiber

- Page 167 and 168:

Gas chromatographic retention indic

- Page 169 and 170:

Outward Foreign Direct Investment f

- Page 171 and 172:

Fiber Nonlinearity Precompensation

- Page 173 and 174:

Improved Nonlinearity precompensati