Workshop proceeding - final.pdf - Faculty of Information and ...

Workshop proceeding - final.pdf - Faculty of Information and ...

Workshop proceeding - final.pdf - Faculty of Information and ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

studies have indicated that surface properties such as surface hydrophilicity <strong>and</strong> charge could affect<br />

cell attachment by influencing the ability <strong>of</strong> the substratum to absorb protein <strong>and</strong>/or by altering the<br />

conformation <strong>of</strong> the absorbed protein[32, 33].<br />

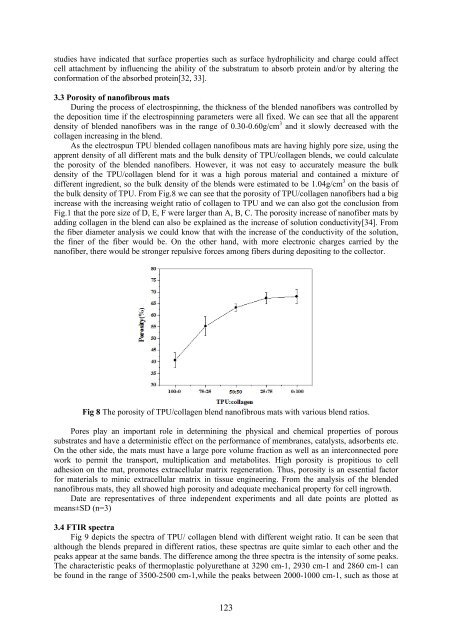

3.3 Porosity <strong>of</strong> nan<strong>of</strong>ibrous mats<br />

During the process <strong>of</strong> electrospinning, the thickness <strong>of</strong> the blended nan<strong>of</strong>ibers was controlled by<br />

the deposition time if the electrospinning parameters were all fixed. We can see that all the apparent<br />

density <strong>of</strong> blended nan<strong>of</strong>ibers was in the range <strong>of</strong> 0.30-0.60g/cm 3 <strong>and</strong> it slowly decreased with the<br />

collagen increasing in the blend.<br />

As the electrospun TPU blended collagen nan<strong>of</strong>ibous mats are having highly pore size, using the<br />

apprent density <strong>of</strong> all different mats <strong>and</strong> the bulk density <strong>of</strong> TPU/collagen blends, we could calculate<br />

the porosity <strong>of</strong> the blended nan<strong>of</strong>ibers. However, it was not easy to accurately measure the bulk<br />

density <strong>of</strong> the TPU/collagen blend for it was a high porous material <strong>and</strong> contained a mixture <strong>of</strong><br />

different ingredient, so the bulk density <strong>of</strong> the blends were estimated to be 1.04g/cm 3 on the basis <strong>of</strong><br />

the bulk density <strong>of</strong> TPU. From Fig.8 we can see that the porosity <strong>of</strong> TPU/collagen nan<strong>of</strong>ibers had a big<br />

increase with the increasing weight ratio <strong>of</strong> collagen to TPU <strong>and</strong> we can also got the conclusion from<br />

Fig.1 that the pore size <strong>of</strong> D, E, F were larger than A, B, C. The porosity increase <strong>of</strong> nan<strong>of</strong>iber mats by<br />

adding collagen in the blend can also be explained as the increase <strong>of</strong> solution conductivity[34]. From<br />

the fiber diameter analysis we could know that with the increase <strong>of</strong> the conductivity <strong>of</strong> the solution,<br />

the finer <strong>of</strong> the fiber would be. On the other h<strong>and</strong>, with more electronic charges carried by the<br />

nan<strong>of</strong>iber, there would be stronger repulsive forces among fibers during depositing to the collector.<br />

Fig 8 The porosity <strong>of</strong> TPU/collagen blend nan<strong>of</strong>ibrous mats with various blend ratios.<br />

Pores play an important role in determining the physical <strong>and</strong> chemical properties <strong>of</strong> porous<br />

substrates <strong>and</strong> have a deterministic effect on the performance <strong>of</strong> membranes, catalysts, adsorbents etc.<br />

On the other side, the mats must have a large pore volume fraction as well as an interconnected pore<br />

work to permit the transport, multiplication <strong>and</strong> metabolites. High porosity is propitious to cell<br />

adhesion on the mat, promotes extracellular matrix regeneration. Thus, porosity is an essential factor<br />

for materials to minic extracellular matrix in tissue engineering. From the analysis <strong>of</strong> the blended<br />

nan<strong>of</strong>ibrous mats, they all showed high porosity <strong>and</strong> adequate mechanical property for cell ingrowth.<br />

Date are representatives <strong>of</strong> three independent experiments <strong>and</strong> all date points are plotted as<br />

means±SD (n=3)<br />

3.4 FTIR spectra<br />

Fig 9 depicts the spectra <strong>of</strong> TPU/ collagen blend with different weight ratio. It can be seen that<br />

although the blends prepared in different ratios, these spectras are quite simlar to each other <strong>and</strong> the<br />

peaks appear at the same b<strong>and</strong>s. The difference among the three spectra is the intensity <strong>of</strong> some peaks.<br />

The characteristic peaks <strong>of</strong> thermoplastic polyurethane at 3290 cm-1, 2930 cm-1 <strong>and</strong> 2860 cm-1 can<br />

be found in the range <strong>of</strong> 3500-2500 cm-1,while the peaks between 2000-1000 cm-1, such as those at<br />

123