Workshop proceeding - final.pdf - Faculty of Information and ...

Workshop proceeding - final.pdf - Faculty of Information and ...

Workshop proceeding - final.pdf - Faculty of Information and ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

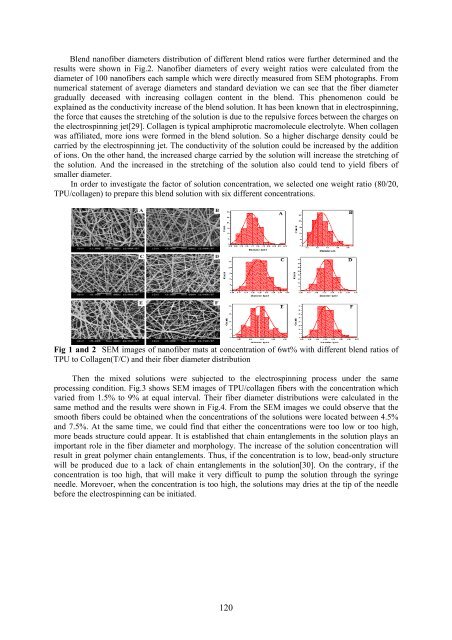

Blend nan<strong>of</strong>iber diameters distribution <strong>of</strong> different blend ratios were further determined <strong>and</strong> the<br />

results were shown in Fig.2. Nan<strong>of</strong>iber diameters <strong>of</strong> every weight ratios were calculated from the<br />

diameter <strong>of</strong> 100 nan<strong>of</strong>ibers each sample which were directly measured from SEM photographs. From<br />

numerical statement <strong>of</strong> average diameters <strong>and</strong> st<strong>and</strong>ard deviation we can see that the fiber diameter<br />

gradually deceased with increasing collagen content in the blend. This phenomenon could be<br />

explained as the conductivity increase <strong>of</strong> the blend solution. It has been known that in electrospinning,<br />

the force that causes the stretching <strong>of</strong> the solution is due to the repulsive forces between the charges on<br />

the electrospinning jet[29]. Collagen is typical amphiprotic macromolecule electrolyte. When collagen<br />

was affiliated, more ions were formed in the blend solution. So a higher discharge density could be<br />

carried by the electrospinning jet. The conductivity <strong>of</strong> the solution could be increased by the addition<br />

<strong>of</strong> ions. On the other h<strong>and</strong>, the increased charge carried by the solution will increase the stretching <strong>of</strong><br />

the solution. And the increased in the stretching <strong>of</strong> the solution also could tend to yield fibers <strong>of</strong><br />

smaller diameter.<br />

In order to investigate the factor <strong>of</strong> solution concentration, we selected one weight ratio (80/20,<br />

TPU/collagen) to prepare this blend solution with six different concentrations.<br />

Fig 1 <strong>and</strong> 2 SEM images <strong>of</strong> nan<strong>of</strong>iber mats at concentration <strong>of</strong> 6wt% with different blend ratios <strong>of</strong><br />

TPU to Collagen(T/C) <strong>and</strong> their fiber diameter distribution<br />

Then the mixed solutions were subjected to the electrospinning process under the same<br />

processing condition. Fig.3 shows SEM images <strong>of</strong> TPU/collagen fibers with the concentration which<br />

varied from 1.5% to 9% at equal interval. Their fiber diameter distributions were calculated in the<br />

same method <strong>and</strong> the results were shown in Fig.4. From the SEM images we could observe that the<br />

smooth fibers could be obtained when the concentrations <strong>of</strong> the solutions were located between 4.5%<br />

<strong>and</strong> 7.5%. At the same time, we could find that either the concentrations were too low or too high,<br />

more beads structure could appear. It is established that chain entanglements in the solution plays an<br />

important role in the fiber diameter <strong>and</strong> morphology. The increase <strong>of</strong> the solution concentration will<br />

result in great polymer chain entanglements. Thus, if the concentration is to low, bead-only structure<br />

will be produced due to a lack <strong>of</strong> chain entanglements in the solution[30]. On the contrary, if the<br />

concentration is too high, that will make it very difficult to pump the solution through the syringe<br />

needle. Morevoer, when the concentration is too high, the solutions may dries at the tip <strong>of</strong> the needle<br />

before the electrospinning can be initiated.<br />

120