IGCAR : Annual Report - Indira Gandhi Centre for Atomic Research

IGCAR : Annual Report - Indira Gandhi Centre for Atomic Research

IGCAR : Annual Report - Indira Gandhi Centre for Atomic Research

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

IGC<br />

<strong>Annual</strong> <strong>Report</strong> 2007<br />

radiation in RCB was 0.3 mR/h,<br />

with a maximum of 1.0 mR/h at<br />

specific locations. A PVC<br />

cocoon was spread over the<br />

pile and hoses provided to<br />

direct the leaking argon to the<br />

exhaust to reduce the activity<br />

inside RCB.<br />

During this experiment the<br />

cover gas was also sampled<br />

and analyzed using Fail Fuel<br />

Localization System (FFLS). The<br />

system per<strong>for</strong>med as per the<br />

design intent and in actual<br />

failure of fuel pin it is expected<br />

to give the age of the failed fuel<br />

pin. Making use of DND<br />

signals, East and West DND<br />

signal ratios and the age of the<br />

failed pin obtained from the<br />

cover gas analysis, the<br />

suspected failed fuel<br />

subassemblies can be short<br />

listed. Actual failed<br />

subassembly can be identified<br />

from this list by limited trial and<br />

error fuel handling and reactor<br />

operations.<br />

I.5. Modification of Trailing Cable System of FBTR to<br />

Minimise Failure of Cores of the Cable<br />

Fuel handling operations in<br />

FBTR are carried out in the<br />

shutdown state of the reactor.<br />

Fuel handling is done through<br />

a single fuel handling canal<br />

which gets aligned over 745<br />

positions of the reactor by<br />

relative rotation of two<br />

eccentrically mounted rotating<br />

plugs, viz. Small Rotating Plug<br />

(SRP) and Large Rotating Plug<br />

(LRP). Prior to plug rotation, the<br />

cables carrying the signals<br />

which are required <strong>for</strong> reactor<br />

operation, but not <strong>for</strong> fuel<br />

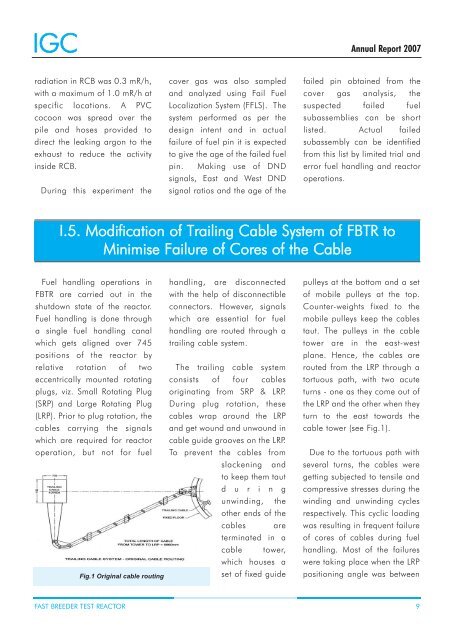

Fig.1 Original cable routing<br />

handling, are disconnected<br />

with the help of disconnectible<br />

connectors. However, signals<br />

which are essential <strong>for</strong> fuel<br />

handling are routed through a<br />

trailing cable system.<br />

The trailing cable system<br />

consists of four cables<br />

originating from SRP & LRP.<br />

During plug rotation, these<br />

cables wrap around the LRP<br />

and get wound and unwound in<br />

cable guide grooves on the LRP.<br />

To prevent the cables from<br />

slackening and<br />

to keep them taut<br />

d u r i n g<br />

unwinding, the<br />

other ends of the<br />

cables are<br />

terminated in a<br />

cable tower,<br />

which houses a<br />

set of fixed guide<br />

pulleys at the bottom and a set<br />

of mobile pulleys at the top.<br />

Counter-weights fixed to the<br />

mobile pulleys keep the cables<br />

taut. The pulleys in the cable<br />

tower are in the east-west<br />

plane. Hence, the cables are<br />

routed from the LRP through a<br />

tortuous path, with two acute<br />

turns - one as they come out of<br />

the LRP and the other when they<br />

turn to the east towards the<br />

cable tower (see Fig.1).<br />

Due to the tortuous path with<br />

several turns, the cables were<br />

getting subjected to tensile and<br />

compressive stresses during the<br />

winding and unwinding cycles<br />

respectively. This cyclic loading<br />

was resulting in frequent failure<br />

of cores of cables during fuel<br />

handling. Most of the failures<br />

were taking place when the LRP<br />

positioning angle was between<br />

FAST BREEDER TEST REACTOR 9