IGCAR : Annual Report - Indira Gandhi Centre for Atomic Research

IGCAR : Annual Report - Indira Gandhi Centre for Atomic Research

IGCAR : Annual Report - Indira Gandhi Centre for Atomic Research

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

IGC<br />

<strong>Annual</strong> <strong>Report</strong> 2007<br />

III.E.7. Characteristics of Debris Bed Formed by Woods<br />

Metal Melt Stream - Water Thermal Interaction<br />

Under a postulated, very low<br />

probability core meltdown<br />

scenario of a Fast Reactor, the<br />

physical status of debris<br />

generated during the molten<br />

fuel interaction with the<br />

coolant, plays a crucial role <strong>for</strong><br />

the post accidental decay heat<br />

removal. Towards this, simulant<br />

thermal interaction experiments<br />

with woods metal melt-water<br />

system under gravity driven<br />

stream mode are being carried<br />

out. The physical properties<br />

(such as density, surface tension<br />

and kinematic viscosity) of<br />

liquid woods metal (a fusible<br />

bismuth based low melting<br />

point alloy with 50 % Bi, 25 %<br />

Pb, 12.5 % Sn, and 12.5 % Cd<br />

with melting point at<br />

345 K) and liquid uranium<br />

dioxide are similar. The low<br />

Fig.1 Melt release system<br />

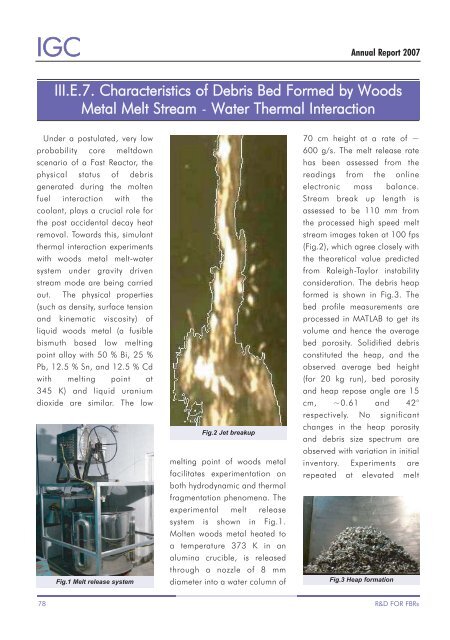

Fig.2 Jet breakup<br />

melting point of woods metal<br />

facilitates experimentation on<br />

both hydrodynamic and thermal<br />

fragmentation phenomena. The<br />

experimental melt release<br />

system is shown in Fig.1.<br />

Molten woods metal heated to<br />

a temperature 373 K in an<br />

alumina crucible, is released<br />

through a nozzle of 8 mm<br />

diameter into a water column of<br />

70 cm height at a rate of ~<br />

600 g/s. The melt release rate<br />

has been assessed from the<br />

readings from the online<br />

electronic mass balance.<br />

Stream break up length is<br />

assessed to be 110 mm from<br />

the processed high speed melt<br />

stream images taken at 100 fps<br />

(Fig.2), which agree closely with<br />

the theoretical value predicted<br />

from Raleigh-Taylor instability<br />

consideration. The debris heap<br />

<strong>for</strong>med is shown in Fig.3. The<br />

bed profile measurements are<br />

processed in MATLAB to get its<br />

volume and hence the average<br />

bed porosity. Solidified debris<br />

constituted the heap, and the<br />

observed average bed height<br />

(<strong>for</strong> 20 kg run), bed porosity<br />

and heap repose angle are 15<br />

cm, ~0.61 and 42°<br />

respectively. No significant<br />

changes in the heap porosity<br />

and debris size spectrum are<br />

observed with variation in initial<br />

inventory. Experiments are<br />

repeated at elevated melt<br />

Fig.3 Heap <strong>for</strong>mation<br />

78 R&D FOR FBRs