IGCAR : Annual Report - Indira Gandhi Centre for Atomic Research

IGCAR : Annual Report - Indira Gandhi Centre for Atomic Research

IGCAR : Annual Report - Indira Gandhi Centre for Atomic Research

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

IGC<br />

<strong>Annual</strong> <strong>Report</strong> 2007<br />

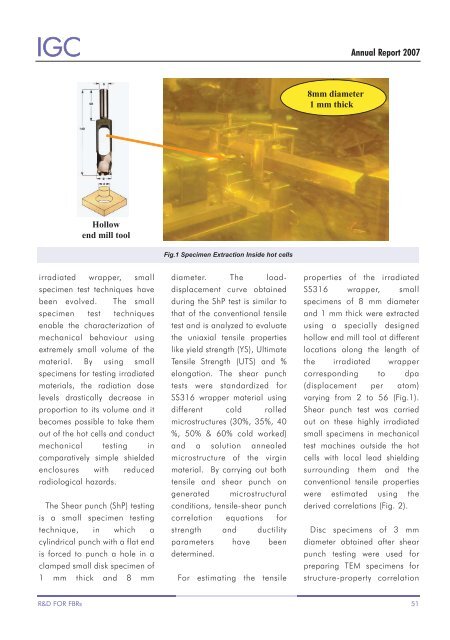

8mm diameter<br />

1 mm thick<br />

Hollow<br />

end mill tool<br />

Fig.1 Specimen Extraction Inside hot cells<br />

irradiated wrapper, small<br />

specimen test techniques have<br />

been evolved. The small<br />

specimen test techniques<br />

enable the characterization of<br />

mechanical behaviour using<br />

extremely small volume of the<br />

material. By using small<br />

specimens <strong>for</strong> testing irradiated<br />

materials, the radiation dose<br />

levels drastically decrease in<br />

proportion to its volume and it<br />

becomes possible to take them<br />

out of the hot cells and conduct<br />

mechanical testing in<br />

comparatively simple shielded<br />

enclosures with reduced<br />

radiological hazards.<br />

The Shear punch (ShP) testing<br />

is a small specimen testing<br />

technique, in which a<br />

cylindrical punch with a flat end<br />

is <strong>for</strong>ced to punch a hole in a<br />

clamped small disk specimen of<br />

1 mm thick and 8 mm<br />

diameter. The loaddisplacement<br />

curve obtained<br />

during the ShP test is similar to<br />

that of the conventional tensile<br />

test and is analyzed to evaluate<br />

the uniaxial tensile properties<br />

like yield strength (YS), Ultimate<br />

Tensile Strength (UTS) and %<br />

elongation. The shear punch<br />

tests were standardized <strong>for</strong><br />

SS316 wrapper material using<br />

different cold rolled<br />

microstructures (30%, 35%, 40<br />

%, 50% & 60% cold worked)<br />

and a solution annealed<br />

microstructure of the virgin<br />

material. By carrying out both<br />

tensile and shear punch on<br />

generated microstructural<br />

conditions, tensile-shear punch<br />

correlation equations <strong>for</strong><br />

strength and ductility<br />

parameters have been<br />

determined.<br />

For estimating the tensile<br />

properties of the irradiated<br />

SS316 wrapper, small<br />

specimens of 8 mm diameter<br />

and 1 mm thick were extracted<br />

using a specially designed<br />

hollow end mill tool at different<br />

locations along the length of<br />

the irradiated wrapper<br />

corresponding to dpa<br />

(displacement per atom)<br />

varying from 2 to 56 (Fig.1).<br />

Shear punch test was carried<br />

out on these highly irradiated<br />

small specimens in mechanical<br />

test machines outside the hot<br />

cells with local lead shielding<br />

surrounding them and the<br />

conventional tensile properties<br />

were estimated using the<br />

derived correlations (Fig. 2).<br />

Disc specimens of 3 mm<br />

diameter obtained after shear<br />

punch testing were used <strong>for</strong><br />

preparing TEM specimens <strong>for</strong><br />

structure-property correlation<br />

R&D FOR FBRs 51