IGCAR : Annual Report - Indira Gandhi Centre for Atomic Research

IGCAR : Annual Report - Indira Gandhi Centre for Atomic Research

IGCAR : Annual Report - Indira Gandhi Centre for Atomic Research

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

IGC<br />

<strong>Annual</strong> <strong>Report</strong> 2007<br />

intermediate and primary<br />

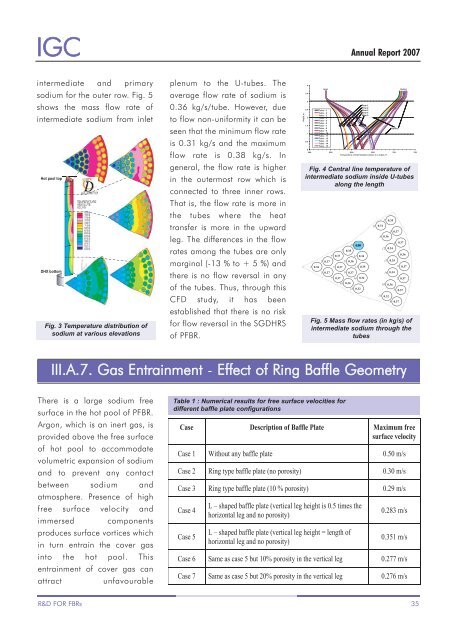

sodium <strong>for</strong> the outer row. Fig. 5<br />

shows the mass flow rate of<br />

intermediate sodium from inlet<br />

Hot pool top<br />

DHX bottom<br />

Fig. 3 Temperature distribution of<br />

sodium at various elevations<br />

plenum to the U-tubes. The<br />

average flow rate of sodium is<br />

0.36 kg/s/tube. However, due<br />

to flow non-uni<strong>for</strong>mity it can be<br />

seen that the minimum flow rate<br />

is 0.31 kg/s and the maximum<br />

flow rate is 0.38 kg/s. In<br />

general, the flow rate is higher<br />

in the outermost row which is<br />

connected to three inner rows.<br />

That is, the flow rate is more in<br />

the tubes where the heat<br />

transfer is more in the upward<br />

leg. The differences in the flow<br />

rates among the tubes are only<br />

marginal (-13 % to + 5 %) and<br />

there is no flow reversal in any<br />

of the tubes. Thus, through this<br />

CFD study, it has been<br />

established that there is no risk<br />

<strong>for</strong> flow reversal in the SGDHRS<br />

of PFBR.<br />

Height, m<br />

4<br />

3.5<br />

3<br />

2.5<br />

2<br />

1.5<br />

1<br />

0.5<br />

0<br />

Inlet<br />

Tube - 1<br />

Tube - 2<br />

Tube - 3<br />

Tube - 4<br />

Tube - 5<br />

Tube - 6<br />

Tube - 7<br />

Tube - 8<br />

Tube - 9<br />

Tube - 10<br />

Tube - 11<br />

Tube - 12<br />

Tube - 13<br />

Tube - 14<br />

Tube - 15<br />

Row-1<br />

Row-2<br />

Row-3<br />

Row-4<br />

Row-5<br />

Baffles<br />

Outlet<br />

500 550 600 650 700 750<br />

Temperature of intermediate sodium in u-tubes, K<br />

Fig. 4 Central line temperature of<br />

intermediate sodium inside U-tubes<br />

along the length<br />

11 0.31<br />

7 0.35<br />

4 0.37 12 0.34<br />

2 0.37 8 0.36<br />

1 0.36 5 0.37 13 0.35<br />

3 0.37 9 0.37<br />

6 0.37 14 0.34<br />

10 0.36<br />

15 0.32<br />

7 0.35<br />

11 0.31<br />

3 0.37<br />

8 0.36<br />

12 0.34<br />

4 0.37<br />

1 0.36<br />

13 0.35<br />

9 0.37<br />

14 0.34<br />

2 0.37<br />

10 0.36<br />

5 0.37<br />

15 0.32<br />

6 0.37<br />

g. 5 Mass flow rates (in kg/s) of intermediate sodium through the<br />

Fig. 5 Mass flow rates (in kg/s) of<br />

intermediate sodium through the<br />

tubes<br />

III.A.7. Gas Entrainment - Effect of Ring Baffle Geometry<br />

There is a large sodium free<br />

surface in the hot pool of PFBR.<br />

Argon, which is an inert gas, is<br />

provided above the free surface<br />

of hot pool to accommodate<br />

volumetric expansion of sodium<br />

and to prevent any contact<br />

between sodium and<br />

atmosphere. Presence of high<br />

free surface velocity and<br />

immersed components<br />

produces surface vortices which<br />

in turn entrain the cover gas<br />

into the hot pool. This<br />

entrainment of cover gas can<br />

attract<br />

unfavourable<br />

Table 1 : Numerical results <strong>for</strong> free surface velocities <strong>for</strong><br />

different baffle plate configurations<br />

R&D FOR FBRs 35