- Page 1 and 2:

EXAMPLE August 23,2007 Mr. Jim Gann

- Page 3 and 4:

TABLE OF CONTENTS Cover Letter & In

- Page 5 and 6:

GENERAL INFORMATION In the evcnt th

- Page 7 and 8:

SCOPE AND OTHER REQUIREMENTS I. Bac

- Page 9 and 10:

Appendix B program. The technical d

- Page 11 and 12:

Telephone: Email: (352) 795-0504 x6

- Page 13 and 14:

Summary Report. lhe selected Vendor

- Page 15 and 16:

limitations. Identify the fire prot

- Page 17 and 18:

for receiving bids. WP documents sh

- Page 19 and 20:

Attachment B. Alternatives Analysis

- Page 21 and 22:

PEF Safety Plan PEF-NCR-0060 1

- Page 23 and 24:

TABLE OF CONTENTS SECTION PAGE 1.0

- Page 25 and 26:

1.0 PURPOSE This procedure provides

- Page 27 and 28:

2.0 REFERENCES 2.46 2.47 2.48 2.49

- Page 29 and 30:

4.0 RESPONSIBILITIES 4.1 Site Vice-

- Page 31 and 32:

9.3 General Rules 9.3.5 Red and bla

- Page 33 and 34:

9.4 Personal Safety Protection 9.4.

- Page 35 and 36:

~~ 9.5 Hearing Conservation 9.5.1 9

- Page 37 and 38:

9.9 Lead 9.9.1 Lead removal shall b

- Page 39 and 40:

9.14 Handling, Use, and Storage of

- Page 41 and 42:

9.17 Fall Protection 9.17.1 Fall pr

- Page 43 and 44:

9.19 Scaffolding 9.19.1 All scaffol

- Page 45 and 46:

9.23 Compressed Air Use 9.23.3 Job-

- Page 47 and 48:

9.29 Job Safety Analysis 9.29.1 Job

- Page 49 and 50:

ATTACHMENT 1 Sheet 2 of 5 29 CFR 19

- Page 51 and 52:

ATTACHMENT 1 Sheet 4 of 5 29 CFR 19

- Page 53 and 54:

ATTACHMENT 2 Sheet 1 of 5 HNP Perso

- Page 55 and 56:

ATTACHMENT 2 Sheet 3 of 5 HNP Perso

- Page 57 and 58:

191 0.1 36 FOOT PROTECTION ATTACHME

- Page 59 and 60:

ATTACHMENT 3 Sheet 2 of 5 RNP Perso

- Page 61 and 62:

ATTACHMENT 3 Sheet 4 of 5 RNP Perso

- Page 63 and 64:

ATTACHMENT 4 Sheet 1 of 2 HE&EC Per

- Page 65 and 66:

ATTACHMENT 5 Sheet 1 of 5 CR3 Perso

- Page 67 and 68:

ATTACHMENT 5 Sheet 3 of 5 CR3 Perso

- Page 69 and 70:

1910.136 FOOT PROTECTION ATTACHMENT

- Page 71 and 72:

ATTACHMENT 6 Sheet 2 of 2 NGG Hazar

- Page 73 and 74:

~~ ATTACHMENT 8 Sheet 1 of 1 Person

- Page 75 and 76:

~~ ____ Section Description of Chan

- Page 77 and 78:

Site Land Use Classification Map PE

- Page 79 and 80:

Applicable Sections of the Site Cer

- Page 81 and 82:

June 2007 2-2 0738953 1 limits the

- Page 83 and 84:

June 2007 1 0738953 SECTION 3 3.0 T

- Page 85 and 86:

June 2007 3-2 0738953 1 3.1.1 Descr

- Page 87 and 88:

June 7007 3 -4 0738953 I 3.4 Air Em

- Page 89 and 90:

June 2007 3 -6 073899 1 emission ra

- Page 91 and 92:

June 2007 3-8 0738953 I designed to

- Page 93 and 94:

June 2007 3-10 0738953 1 1 1.4 perc

- Page 95 and 96:

June 2007 I 0738953 1 SECTION 5 5.0

- Page 97 and 98:

June 2007 5- 1 0738953 1 5.0 EFFECT

- Page 99 and 100:

June 2007 5 -3 0738953 I 5.1.3 Biol

- Page 101 and 102:

Figure 2.3.4-5 Once Through Cooling

- Page 103 and 104:

Helper Cooling Tower Performance Cu

- Page 105 and 106:

Modular Cooling Tower Performance C

- Page 107 and 108:

Local Annual Windrose

- Page 109 and 110:

5/24/2007 2 3 7-2 TPA Winter Windro

- Page 111 and 112:

5/24/2007 2.3.7-4 TPA Surnrner Wind

- Page 113 and 114:

RFI Number: Discharge Canal Thermal

- Page 115 and 116:

Inhattsverzeichnis I Table of conte

- Page 117 and 118:

Qu alitats p r u f blattlQuality Te

- Page 119 and 120:

Qualit~tsprufbla~Quality Test Sheet

- Page 121 and 122:

Kennwort: Job "0: AuRrags-N.: etm m

- Page 123 and 124:

QualitSts pr UfblatUQuality I Test

- Page 125 and 126:

SIEMENS McdernaalKm prolecf CONFIDE

- Page 127 and 128:

SUSQUEHANNA STEAM ELECTRIC STATION

- Page 129 and 130:

OTHER LONG TERM RELIABILITY ISSUES

- Page 131 and 132:

Figure 1 -Advanced Disc Design LP T

- Page 133 and 134:

stainless steel inner casing constr

- Page 135 and 136:

Figure 2 - HP Turbine Comparison (U

- Page 137 and 138:

~ ~~ SCOPE OF SUPPLY - HARDWARE SIE

- Page 139 and 140:

SIEMENS CONF Mdernaalion Roied PAGE

- Page 141 and 142:

SIEMENS co ~N FI DENTI At DO USE 7H

- Page 143 and 144:

SIEMENS Modernnation Prolect ADril

- Page 145 and 146:

SCOPE OF SUPPLY - HARDWARE SIEMENS

- Page 147 and 148:

SIEMENS co Modernizetion Proled ..

- Page 149 and 150:

Moderncalfon Pmpd PAGE5 SCOPE OF SU

- Page 151 and 152:

SIEMENS Modernnebon Propa April 16

- Page 153 and 154:

COMPATIBILITY WITH EXISTING PLANT S

- Page 155 and 156:

SIEMENS Scope of Supply GENERATOR S

- Page 157 and 158:

SIEMENS Mcdemnahon Pnyect Page 3 Ap

- Page 159 and 160:

Supply of Equipment Contracts for n

- Page 161 and 162:

e e Interface with the customer, co

- Page 163 and 164:

CRAFT LABOR EXTRA WORK RATES SIEMEN

- Page 165 and 166:

SIEMENS Modernnabon Projecl Pdge 2

- Page 167 and 168:

SIEMENS Request No SKI22037 Use thi

- Page 169 and 170:

Use rhJ documenr solely for rhe pur

- Page 171 and 172:

SIEMENS ,. ._ - _. . - . . , April

- Page 173 and 174:

a Siemens Contract #I 45569 Work Au

- Page 175 and 176:

iemens Contra roiect Schedule C 0 :

- Page 177 and 178:

ontrac t Sum mar Savings ($000's) A

- Page 180 and 181:

Warranty PEF-NCR-00762

- Page 182 and 183:

Limits of Liability

- Page 184 and 185:

Siemens Contract Summary: 201 I Del

- Page 186 and 187:

0 Siemens Contract Summary: Proiect

- Page 188:

Alstom Initial ProuosalS-ummaw: ..

- Page 191 and 192:

02/28/2607 12:24 412-374-4011 I~ I.

- Page 193 and 194:

Siemens Scope of Supply Comments Ge

- Page 195 and 196:

2P Pg. 1 of 3 iemens Proposal #SD22

- Page 197 and 198:

a Pg. 2 of 3 Turbine Testing: Propo

- Page 199 and 200:

iemens Proposal #SD22007, CR3 Turbi

- Page 201 and 202:

f I Crystal River 3 Generator Cross

- Page 203 and 204:

Siemens Generator Workshop Feb 57,2

- Page 205 and 206:

0 H2 gland seal rings Bearing refur

- Page 207 and 208:

0 Advanced Hydrogen Cooled Stator D

- Page 209 and 210:

February 16,2007 Siemens Power Gene

- Page 211:

OPC ST 1 POD #1 080009 BATES NOS. P

- Page 215 and 216:

Quality Management Manual (QMM 602)

- Page 217 and 218:

Quality Management Manual (QMM 602)

- Page 219 and 220:

Quality Management Manual (QMM 602)

- Page 221 and 222:

Quality Management Manual (QMM 602)

- Page 223 and 224:

Quality Management Manual (QMM 602)

- Page 225:

Quality Management Manual (QMM 602)

- Page 228 and 229:

Progress Energy Florida, Inc. Cryst

- Page 230 and 231:

GENERAL INFORMATION In the event th

- Page 232 and 233:

SCOPE AND OTHER REQUIREMENTS I. Bac

- Page 234 and 235:

Appendix B program. The technical d

- Page 236 and 237:

Telephone: Email: (352) 795-0504 x6

- Page 238 and 239:

Summary Report. The selected Vendor

- Page 240 and 241:

limitations. Identify the fire prot

- Page 242 and 243:

for receiving bids. RFP documents s

- Page 244 and 245:

1. 2. 3. 4. 5. 6. Attachment 6. Alt

- Page 246 and 247:

PEF Safety Plan 18

- Page 248 and 249:

Applicable Sections of the Site Cer

- Page 250 and 251:

Helper Cooling Tower Performance Cu

- Page 252 and 253:

Local Annual Windrose 24

- Page 254 and 255:

April 10, 2008 Attn: Subject : Prog

- Page 256 and 257:

ACKNOWLEDGEMENT To: Deborah Hanna P

- Page 258 and 259:

Contractor's License Number (if app

- Page 260 and 261:

schedule for the Project’s implem

- Page 262 and 263:

. 3 90 O F Design Outlet Temperatur

- Page 264 and 265:

0 Projected EAC 0 Accomplishments 0

- Page 266 and 267:

October 13,2006 AR WA-06-2792 Mr. D

- Page 268 and 269:

AREVA NP InC. Proposal #4 161084 PR

- Page 270 and 271:

AREVA NP Inc. Proposal #4167084 - E

- Page 272 and 273:

AREVA NP Inc. Proposal #4161084 PRO

- Page 274 and 275:

AREVA NP Inc. Proposal #416 1084 PR

- Page 276 and 277:

AREVA NP Inc. Proposal #4161084 PRO

- Page 278 and 279:

AREVA NP Iflc. Proposal #4161084 PR

- Page 280 and 281:

CR-3 Power Uprate Project a Progres

- Page 282 and 283:

AREVA NP Inc. Proposal #4767084 PRO

- Page 284 and 285:

AREVA NP lnc. Proposal #4161084 PRO

- Page 286 and 287:

AREVA NP Inc. Proposal #4 161084 PR

- Page 288 and 289:

AREVA Inc. Proposal #4161084 PROPRI

- Page 290 and 291:

AREVA Inc. Proposal#4161084 PROPRIE

- Page 292 and 293:

CR-3 Power Uprate Project 20 Progre

- Page 294 and 295:

AREVA Inc. Proposal #4 161084 PROPR

- Page 296 and 297:

AREVA Inc. Proposal #4161084 PROPRI

- Page 298 and 299:

AREVA Inc. Proposal #4 I6 7084 PROP

- Page 300 and 301:

CR-3 Power Uprate Project 28 Ppgres

- Page 302 and 303:

AREVA Inc. Proposal #47 61084 PROPR

- Page 304 and 305:

AREVA Inc. Proposal #4161084 PROPRI

- Page 306 and 307:

AREVA Inc. Proposal #4167084 PROPRI

- Page 308:

A REVd inc. Proposal #47 67084 PROP

- Page 311 and 312:

AREVA NP Inc P ROPRl ETARY - PENG07

- Page 313 and 314:

ktum this Propsat, If requested. Pa

- Page 315 and 316:

AREVA NP inc PROPRl ETARY PENG07-13

- Page 317 and 318:

OPC 1 st POD #1 080009 BATES NOS. P

- Page 319 and 320:

SIEMENS Modernnabon Pwnf Apnl 16 xx

- Page 321 and 322:

I .- . -.. .,. Awl 16. 2007 Pqress

- Page 325 and 326:

w a

- Page 327 and 328:

SIEMENS Mcdwnaafion Roj& April 16,

- Page 329 and 330:

SIEMENS PAOE 2 Semens Confidential

- Page 331 and 332:

Mcdernuabon Projecl PPQE4 Generala

- Page 333 and 334:

Modernnabon hied Apnll6, XO7 PAGE6

- Page 335 and 336:

SEMENS Mcdernaabon proled Aprrl 16.

- Page 337 and 338: SIEMENS McdwnrzeOon Prolecl PAOE 10

- Page 339 and 340: MODERNIZED EXPERIENCE LIST SIEMENS

- Page 341 and 342: MODERNIZED EXPERIENCE LIST SIEMENS

- Page 343: SIEMENS

- Page 349 and 350: -1 F: i= Lu P w

- Page 351 and 352: All requests for clarifications, in

- Page 353 and 354: GENERAL IhTORMATION PROGRESS ENERGY

- Page 355 and 356: SCOPE AND OTHER REOUIREMENTS PROGRE

- Page 357 and 358: sizc or quantity. Further, in the e

- Page 359 and 360: Schedule Risk: agreement to h ish s

- Page 361 and 362: ..ll-.l-l_l..--l.-l-- I - Progress

- Page 363 and 364: OPC ST 1 POD #1 080009 BATES NOS. P

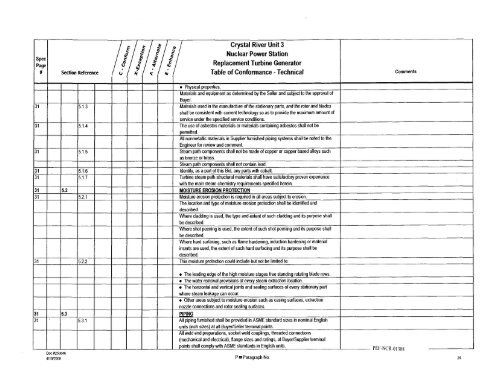

- Page 365 and 366: Spec Page Crystal River Unit 3 Nucl

- Page 367 and 368: Spec Page # Nuclear Power Station R

- Page 369 and 370: Spec Page I Crystal River Unit 3 Nu

- Page 371 and 372: Section Reference Replacement Turbi

- Page 373 and 374: Crystal River Unit 3 Nuclear Power

- Page 376 and 377: Crystal River Unit 3 Nuclear Power

- Page 378 and 379: Section Reference 1.11.11 1.11.12 1

- Page 380 and 381: Crystal River Unit 3 Nuclear Power

- Page 382 and 383: Section Reference / d Crystal River

- Page 384 and 385: Spec Page # Crystal River Unit 3 Nu

- Page 386 and 387: ~ Spec Page # 29 _. 29 - 29 - 29 29

- Page 390 and 391: spec Page # Section Reference Cryst

- Page 392 and 393: Spec Page # Section Reference I I C

- Page 394: t E E, 0 0 z c n 6 e h I1 n

- Page 397 and 398: f c ALST6)M I Power Systems May 30,

- Page 399 and 400: Alstom Power Inc. 2800 Waterford La

- Page 401 and 402: ” . . v 111 Crystal River Nuclear

- Page 403 and 404: c Commercial Volume (U n pr iced) 2

- Page 405 and 406: Alstom Proposal # SD22007, CR3 EPU

- Page 407 and 408: Alstom Proposal # SD22007, CR3 EPU

- Page 409 and 410: Alstom Proposal # SD22007, CR3 EPU

- Page 411 and 412: Alstom Proposal # SD22007, CR3 EPU

- Page 413 and 414: I ' Our proposal offers a strong te

- Page 415 and 416: ENERCON SERVICES, INC. Proprietary

- Page 418 and 419: ENERCON SERVICES, INC. 5.0 ORGANIZA

- Page 420 and 421: CR3 Extended Power Uprate, Secondar

- Page 422 and 423: CR3 Extended Power Uprate, secondar

- Page 424 and 425: CR3 Extended Power Uprate, Secondar

- Page 426 and 427: September 4,2007 Page 2 Addendum to

- Page 429: CONFIDENTlF.? September 4,2007 Page

- Page 437: CONFIDEMTIP,!.

- Page 445 and 446:

Daie TU; 9/4/07 Milestone Project S

- Page 447:

1 Dace Tue 9/4/07 Milestone Prqed S

- Page 453 and 454:

D Computer Model Updates o PEPSE- h

- Page 455 and 456:

D D D D D D D Feedwater Control Val

- Page 458 and 459:

D AREVA has full time employees wit

- Page 460 and 461:

I W

- Page 462 and 463:

~ AREVA - has a proven track record

- Page 464 and 465:

Per the reement #I 01659, the LOL c

- Page 466 and 467:

CR3 Extended Power Uprste, Secondar

- Page 468 and 469:

. - * CR3 Extended Power Umate, Sec

- Page 470 and 471:

(IHJ i3dendecl I'ower Ulirate, Seco

- Page 473 and 474:

CONFIDENTlP!-

- Page 475:

a CONFIDENTIP.!m PEF-NCR-01659

- Page 480 and 481:

PROPRIETARY 20440-1 2 f3/30/2006) T

- Page 482 and 483:

-- AREVA NP Inc. PROPRIETARY a CONF

- Page 484 and 485:

July 27,2005 PROGRESS ENERGY SERVIC

- Page 486 and 487:

Attachment A to Request No. KS12007

- Page 488 and 489:

.. Clarlflcation on the 1CS system:

- Page 490 and 491:

June 6,2007 Attention : PROGRESS EN

- Page 492 and 493:

ACKNOWLEDGEMENT Mr. Tony Owen Progr

- Page 494 and 495:

In accordance with the Federal Acqu

- Page 496 and 497:

SCOPE AND OTHER REOUIREMENTS PROGRE

- Page 498 and 499:

place in the proposal at the expens

- Page 500 and 501:

other information provided in its p

- Page 502 and 503:

a ProgressEnergy Contractor's Safet

- Page 504 and 505:

1 P96 I O-XJN-d3d

- Page 506 and 507:

~ ____, Crystal River Unit 3 Nuclea

- Page 508 and 509:

Progress Energy Crystal River Unit

- Page 510 and 511:

Progress Energy Crystal River Unit

- Page 512 and 513:

Progress Energy Crystal River Unit

- Page 514 and 515:

Progress Energy Crystal River Unit

- Page 516 and 517:

Progress Energy Crystal River Unit

- Page 518 and 519:

Progress Energy Crystal River Unit

- Page 520 and 521:

Progress Energy Crystal River Unit

- Page 522 and 523:

Progress Energy Crystal River Unit

- Page 524 and 525:

Progress Energy Crystal River Unit

- Page 526 and 527:

Progress Energy Crystal River Unit

- Page 528 and 529:

P Progress Energy Crystal River Uni

- Page 530 and 531:

Progress Energy Crystal River Unit

- Page 532 and 533:

Progress Energy Crystal River Unit

- Page 534 and 535:

Progress Energy Crystal River Unit

- Page 536 and 537:

Progress Energy Crystal River Unit

- Page 538 and 539:

Progress Energy Crystal River Unit

- Page 540 and 541:

Progress Energy Crystal River Unit

- Page 542 and 543:

Progress Energy Crystal River Unit

- Page 544 and 545:

Progress Energy Crystal River Unit

- Page 546 and 547:

Progress Energy Crystal River Unit

- Page 548 and 549:

Progress Energy Crystal River Unit

- Page 550 and 551:

Progress Energy Crystat River Unit

- Page 553 and 554:

April 10,2008 PROGRESS ENERGY SERVI

- Page 555 and 556:

Attachment A to Request No. KS12007

- Page 557 and 558:

Clarification on the ICs system: At

- Page 559 and 560:

CR3 Extended Power Uprate, Secondar

- Page 561 and 562:

CR3 Extended Power Uprate, Secondar

- Page 563 and 564:

Proposal for Design Engineering of

- Page 565 and 566:

Tech Com International 440 Goddard

- Page 567 and 568:

Tech Com International 440 Goddard

- Page 569 and 570:

Tech Coin International 440 Goddard

- Page 571 and 572:

Tech Com International 440 Goddard

- Page 573 and 574:

~ ~~~ Tech Com Intern ation a1 440

- Page 575 and 576:

Tech Com International 440 Goddard

- Page 577 and 578:

~~~ ~ ~ ~~ ~ ~~~ ~ Tech Com Interna

- Page 579 and 580:

PEF-NCR-02039

- Page 581 and 582:

Spec Page tt section Reference Crys

- Page 583 and 584:

Comments I 1 I I I I I I I and 18 t

- Page 585 and 586:

Spec Page # Mion Reference Crystal

- Page 588 and 589:

N B 00

- Page 590 and 591:

CR3 Extended Power Uprate, Secondar

- Page 592 and 593:

CR3 Extended Power Uprate, Secondar

- Page 594 and 595:

.. CR3 Extended Power Uerate, Secon

- Page 596 and 597:

Mr. Tony Owen Progress Energy Augus

- Page 610 and 611:

JOB NO. PROPOSAL "RADIUSED HOLE" MS

- Page 613 and 614:

ARRANGEMENT FOR STACKING AND JACKIN

- Page 617 and 618:

a CONFIDENTlrl!

- Page 619 and 620:

n a. TlEi Document Number: 07-924 P

- Page 621 and 622:

1. Outline Drawings ....... 19 2. D

- Page 623 and 624:

OPC ST 1 POD 080009 BATES NOS. PEF-

- Page 625 and 626:

‘El Contract Summary on tents: a

- Page 627 and 628:

TEI Contract Summary Payment Milest

- Page 630 and 631:

TEI Contract Summary Performance Li

- Page 632:

REDACTED Corrective Measures: - - -

- Page 635 and 636:

'El Contract Sumrr iar roject Revie

- Page 637 and 638:

Document Number: 07-248 Proposal Nu

- Page 639 and 640:

Page 4.0 TECHNICAL 4.1 Performance

- Page 641 and 642:

Finally, this unsolicited proposal

- Page 643 and 644:

1. 2. 3. 4. 5. 6. 7. 8. On the spot

- Page 645 and 646:

The TEI resources provisions are: a

- Page 649 and 650:

4.0 TECHNICAL 4.1 Performance The p

- Page 651 and 652:

8. The 4-pass box redesign assures

- Page 653 and 654:

The design incorporates the state-o

- Page 655 and 656:

e e e A higher structural integrity

- Page 657 and 658:

4.4 MSR Performance Tests 4.4.1 Sco

- Page 660:

n .L a W 2

- Page 668 and 669:

Lfl CONFIDENTIFr!. JOB NO. PROPOSAL

- Page 670 and 671:

PROPOSAL FUNCTION OF BY-PASS RESTRI

- Page 674 and 675:

-1 r. m N N ? e: ? w" a

- Page 676 and 677:

a CONFIDENTIAL PEF-NCR-02239