RD&D-Programme 2004 - SKB

RD&D-Programme 2004 - SKB

RD&D-Programme 2004 - SKB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

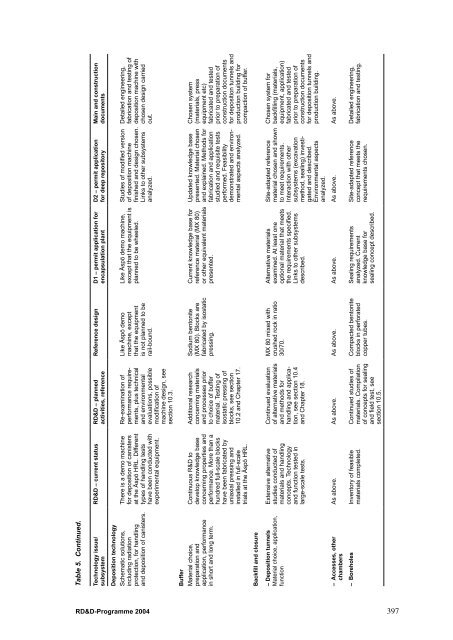

Table 5. Continued.<br />

Technology issue/<br />

subsystem<br />

RD&D – current status RD&D – planned<br />

activities, reference<br />

Reference design D1 – permit application for<br />

encapsulation plant<br />

D2 – permit application<br />

for deep repository<br />

Main and construction<br />

documents<br />

Deposition technology<br />

Schematic solutions,<br />

including radiation<br />

protection, for handling<br />

and deposition of canisters.<br />

There is a demo machine<br />

for deposition of canisters<br />

at the Äspö HRL. Different<br />

types of handling tests<br />

have been conducted with<br />

experimental equipment.<br />

Re-examination of<br />

performance requirements,<br />

plus technical<br />

and environmental<br />

evaluations, possible<br />

modification of<br />

machine design, see<br />

section 10.3.<br />

Like Äspö demo<br />

machine, except<br />

that the equipment<br />

is not planned to be<br />

rail-bound.<br />

Like Äspö demo machine,<br />

except that the equipment is<br />

planned to be wheeled.<br />

Studies of modified version<br />

of deposition machine<br />

finished and design chosen.<br />

Links to other subsystems<br />

analyzed.<br />

Detailed engineering,<br />

fabrication and testing of<br />

deposition machine with<br />

chosen design carried<br />

out.<br />

Buffer<br />

Material choice,<br />

preparation and<br />

application, performance<br />

in short and long term.<br />

Continuous R&D to<br />

develop knowledge base<br />

concerning properties and<br />

performance. More than a<br />

hundred full-scale blocks<br />

have been fabricated by<br />

uniaxial pressing and<br />

installed in full-scale<br />

trials at the Äspö HRL.<br />

Additional research<br />

concerning materials<br />

and processes prior<br />

to choice of buffer<br />

material. Testing of<br />

isostatic pressing of<br />

blocks, see section<br />

10.2 and Chapter 17.<br />

Sodium bentonite<br />

(MX 80). Blocks are<br />

fabricated by isostatic<br />

pressing.<br />

Current knowledge base for<br />

reference material (MX 80)<br />

or other equivalent materials<br />

presented.<br />

Updated knowledge base<br />

presented. Material chosen<br />

and explained. Methods for<br />

fabrication and application<br />

studied and requisite tests<br />

performed. Feasibility<br />

demonstrated and environmental<br />

aspects analyzed.<br />

Chosen system<br />

(materials, press<br />

equipment etc)<br />

fabricated and tested<br />

prior to preparation of<br />

construction documents<br />

for deposition tunnels and<br />

production building for<br />

compaction of buffer.<br />

Backfill and closure<br />

– Deposition tunnels<br />

Material choice, application,<br />

function<br />

Extensive alternative<br />

studies conducted of<br />

materials and handling<br />

concepts. Technology<br />

and function tested in<br />

large-scale tests.<br />

Continued evaluation<br />

of alternative materials<br />

and methods for<br />

handling and application,<br />

see section 10.4<br />

and Chapter 18.<br />

MX 80 mixed with<br />

crushed rock in ratio<br />

30/70.<br />

Alternative materials<br />

examined. At least one<br />

optional material that meets<br />

the requirements specified.<br />

Links to other subsystems<br />

described.<br />

Site-adapted reference<br />

material chosen and shown<br />

to meet requirements.<br />

Interaction with other<br />

subsystems (excavation<br />

method, sealing) investigated<br />

and described.<br />

Environmental aspects<br />

analyzed.<br />

Chosen system for<br />

backfilling (materials,<br />

equipment, application)<br />

fabricated and tested<br />

prior to preparation of<br />

construction documents<br />

for deposition tunnels and<br />

production building.<br />

– Accesses, other<br />

chambers<br />

As above. As above. As above. As above. As above. As above.<br />

– Boreholes Inventory of feasible<br />

materials completed.<br />

Continued studies of<br />

materials. Compilation<br />

of concepts for sealing<br />

and field test, see<br />

section 10.5.<br />

Compacted bentonite<br />

blocks in perforated<br />

copper tubes.<br />

Sealing requirements<br />

analyzed. Current<br />

knowledge base for<br />

sealing concept described.<br />

Site-adapted reference<br />

concept that meets the<br />

requirements chosen.<br />

Detailed engineering,<br />

fabrication and testing.<br />

RD&D-<strong>Programme</strong> <strong>2004</strong> 397