iaea human health series publications - SEDIM

iaea human health series publications - SEDIM

iaea human health series publications - SEDIM

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

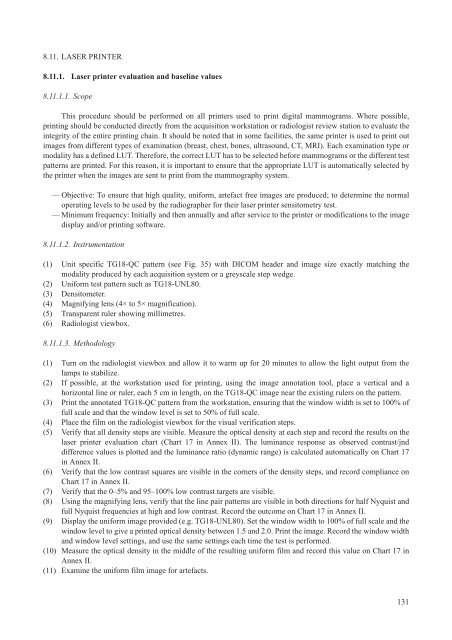

8.11. LASER PRINTER8.11.1. Laser printer evaluation and baseline values8.11.1.1. ScopeThis procedure should be performed on all printers used to print digital mammograms. Where possible,printing should be conducted directly from the acquisition workstation or radiologist review station to evaluate theintegrity of the entire printing chain. It should be noted that in some facilities, the same printer is used to print outimages from different types of examination (breast, chest, bones, ultrasound, CT, MRI). Each examination type ormodality has a defined LUT. Therefore, the correct LUT has to be selected before mammograms or the different testpatterns are printed. For this reason, it is important to ensure that the appropriate LUT is automatically selected bythe printer when the images are sent to print from the mammography system.— Objective: To ensure that high quality, uniform, artefact free images are produced; to determine the normaloperating levels to be used by the radiographer for their laser printer sensitometry test.— Minimum frequency: Initially and then annually and after service to the printer or modifications to the imagedisplay and/or printing software.8.11.1.2. Instrumentation(1) Unit specific TG18-QC pattern (see Fig. 35) with DICOM header and image size exactly matching themodality produced by each acquisition system or a greyscale step wedge.(2) Uniform test pattern such as TG18-UNL80.(3) Densitometer.(4) Magnifying lens (4× to 5× magnification).(5) Transparent ruler showing millimetres.(6) Radiologist viewbox.8.11.1.3. Methodology(1) Turn on the radiologist viewbox and allow it to warm up for 20 minutes to allow the light output from thelamps to stabilize.(2) If possible, at the workstation used for printing, using the image annotation tool, place a vertical and ahorizontal line or ruler, each 5 cm in length, on the TG18-QC image near the existing rulers on the pattern.(3) Print the annotated TG18-QC pattern from the workstation, ensuring that the window width is set to 100% offull scale and that the window level is set to 50% of full scale.(4) Place the film on the radiologist viewbox for the visual verification steps.(5) Verify that all density steps are visible. Measure the optical density at each step and record the results on thelaser printer evaluation chart (Chart 17 in Annex II). The luminance response as observed contrast/jnddifference values is plotted and the luminance ratio (dynamic range) is calculated automatically on Chart 17in Annex II.(6) Verify that the low contrast squares are visible in the corners of the density steps, and record compliance onChart 17 in Annex II.(7) Verify that the 0–5% and 95–100% low contrast targets are visible.(8) Using the magnifying lens, verify that the line pair patterns are visible in both directions for half Nyquist andfull Nyquist frequencies at high and low contrast. Record the outcome on Chart 17 in Annex II.(9) Display the uniform image provided (e.g. TG18-UNL80). Set the window width to 100% of full scale and thewindow level to give a printed optical density between 1.5 and 2.0. Print the image. Record the window widthand window level settings, and use the same settings each time the test is performed.(10) Measure the optical density in the middle of the resulting uniform film and record this value on Chart 17 inAnnex II.(11) Examine the uniform film image for artefacts.131