- Page 1 and 2:

advanced building skins 14 | 15 Jun

- Page 3 and 4:

Editorial advanced building skins -

- Page 5 and 6:

ABS_07 Lucio Blandini Timo Schmidt

- Page 7 and 8:

Prof. Dr.nat.techn. Oliver Englhard

- Page 9 and 10:

Advanced Building Skins Figure 3: A

- Page 11 and 12:

2.2 Geometrical Processing Advanced

- Page 13 and 14:

3 Digital Data Advanced Building Sk

- Page 15 and 16:

4 References Advanced Building Skin

- Page 17 and 18:

Advanced Building Skins 2 The Creat

- Page 19 and 20:

Advanced Building Skins Figure 5: f

- Page 21 and 22:

Advanced Building Skins The next st

- Page 23 and 24:

Advanced Building Skins The Kilden

- Page 25 and 26:

2.1 Maintenance Advanced Building S

- Page 27 and 28:

4.2 Fire Protection Advanced Buildi

- Page 29 and 30:

7 Acknowledgements Advanced Buildin

- Page 31 and 32:

2 Cable-Stayed Glass Façade Advanc

- Page 33 and 34:

Advanced Building Skins The outer s

- Page 35 and 36:

Advanced Building Skins Figure 10:

- Page 37 and 38:

Advanced Building Skins Figure 1 a

- Page 39 and 40:

Advanced Building Skins Figure 5: S

- Page 41 and 42:

Advanced Building Skins Figure 11:

- Page 43 and 44:

Prof. Dr.nat.techn. Oliver Englhard

- Page 45 and 46:

Advanced Building Skins Figure 2: H

- Page 47 and 48:

4.1 Schüco Aluminium Window System

- Page 49 and 50:

Advanced Building Skins 5 Installat

- Page 51 and 52: Advanced Building Skins Figure 1: B

- Page 53 and 54: Advanced Building Skins Another pro

- Page 55 and 56: 2.2 Variety of Solutions Advanced B

- Page 57 and 58: Advanced Building Skins Air exchang

- Page 59 and 60: Advanced Building Skins Bq/m 3 in t

- Page 61 and 62: Advanced Building Skins Usually the

- Page 63 and 64: Advanced Building Skins Figure 5: T

- Page 65 and 66: 10 References Advanced Building Ski

- Page 67 and 68: Advanced Building Skins Figure 1: P

- Page 69 and 70: Advanced Building Skins Likewise, a

- Page 71 and 72: 3.2 Method Advanced Building Skins

- Page 73 and 74: Advanced Building Skins 3.4 Sensiti

- Page 75 and 76: Advanced Building Skins Figure 9: V

- Page 77 and 78: Prof. Dr.nat.techn. Oliver Englhard

- Page 79 and 80: Advanced Building Skins Planning te

- Page 81 and 82: Insulation material Glass wool boar

- Page 83 and 84: Primary energy, non renewable kWh p

- Page 85 and 86: Advanced Building Skins timber fram

- Page 87 and 88: Prof. Dr.nat.techn. Oliver Englhard

- Page 89 and 90: Advanced Building Skins Figure 1: C

- Page 91 and 92: Advanced Building Skins 2.1 Interna

- Page 93 and 94: 2.2.2 ÖGNB (TQB) Advanced Building

- Page 95 and 96: Advanced Building Skins Again the p

- Page 97 and 98: Advanced Building Skins Table 1: As

- Page 99 and 100: Advanced Building Skins [6] Interna

- Page 101: Prof. Dr.nat.techn. Oliver Englhard

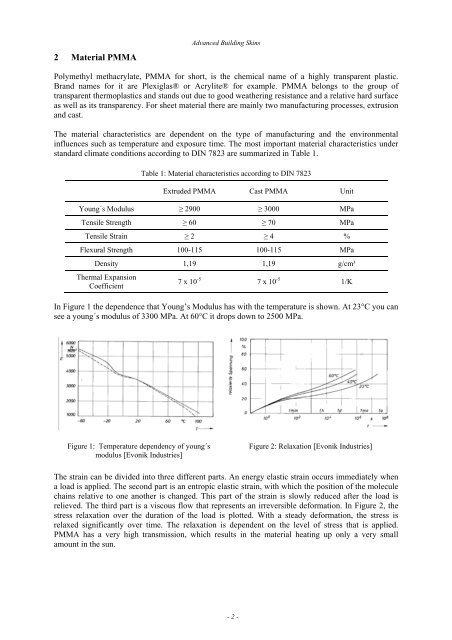

- Page 105 and 106: Advanced Building Skins properties

- Page 107 and 108: Prof. Dr.nat.techn. Oliver Englhard

- Page 109 and 110: Advanced Building Skins tensile str

- Page 111 and 112: Advanced Building Skins Deep drawin

- Page 113 and 114: Advanced Building Skins Ellipsoid o

- Page 115 and 116: Advanced Building Skins 4.3 Creatio

- Page 117 and 118: Prof. Dr.nat.techn. Oliver Englhard

- Page 119 and 120: Advanced Building Skins Figure 2: N

- Page 121 and 122: Advanced Building Skins Of the two

- Page 123 and 124: Advanced Building Skins correspond

- Page 125 and 126: 8 References Advanced Building Skin

- Page 127 and 128: Advanced Building Skins 1 Shells in

- Page 129 and 130: a) A.3a. Selection of segments A.4a

- Page 131 and 132: 4.1 Material Properties Advanced Bu

- Page 133 and 134: 5 Connecting Methods Advanced Build

- Page 135 and 136: Prof. Dr.nat.techn. Oliver Englhard

- Page 137 and 138: 5 Innovative Material Use 5.1 Struc

- Page 139 and 140: Advanced Building Skins Figure 5: S

- Page 141 and 142: 8 Conclusion Advanced Building Skin

- Page 143 and 144: Prof. Dr.nat.techn. Oliver Englhard

- Page 145 and 146: 2.2 Contact Materials Advanced Buil

- Page 147 and 148: 3.1 Rectangular Glass Fins Advanced

- Page 149 and 150: Advanced Building Skins Figure 9 sh

- Page 151 and 152: Prof. Dr.nat.techn. Oliver Englhard

- Page 153 and 154:

Advanced Building Skins 3 Design Me

- Page 155 and 156:

Advanced Building Skins This compar

- Page 157 and 158:

Advanced Building Skins weight plus

- Page 159 and 160:

Advanced Building Skins For the fra

- Page 161 and 162:

8 References Advanced Building Skin

- Page 163 and 164:

Advanced Building Skins round court

- Page 165 and 166:

Advanced Building Skins 4 Cone 5 -

- Page 167 and 168:

Advanced Building Skins Y Z Figure

- Page 169 and 170:

Prof. Dr.nat.techn. Oliver Englhard

- Page 171 and 172:

1.2 Mapping Advanced Building Skins

- Page 173 and 174:

Advanced Building Skins Figure 2: A

- Page 175 and 176:

Advanced Building Skins In addition

- Page 177 and 178:

Advanced Building Skins process und

- Page 179 and 180:

Prof. Dr.nat.techn. Oliver Englhard

- Page 181 and 182:

Advanced Building Skins does not co

- Page 183 and 184:

Advanced Building Skins such materi

- Page 185 and 186:

Advanced Building Skins reduced. Th

- Page 187 and 188:

Advanced Building Skins Due to its

- Page 189 and 190:

Prof. Dr.nat.techn. Oliver Englhard

- Page 191 and 192:

Advanced Building Skins Compared t

- Page 193 and 194:

Test number Inlet temperature [°C]

- Page 195 and 196:

Advanced Building Skins The next se

- Page 197 and 198:

Prof. Dr.nat.techn. Oliver Englhard

- Page 199 and 200:

Rdd [-] 0.50 0.45 0.40 0.35 0.30 0.

- Page 201 and 202:

E [kWh/m²/ ° Advanced Building Sk

- Page 203 and 204:

+110 +100 West +80 +120 +70 +60 +13

- Page 205 and 206:

3 Summary Advanced Building Skins T

- Page 207 and 208:

1 Introduction Advanced Building Sk

- Page 209 and 210:

Advanced Building Skins facade. The

- Page 211 and 212:

Advanced Building Skins Figure 4: T

- Page 213 and 214:

5 Photometric investigations Advanc

- Page 215 and 216:

Prof. Dr.nat.techn. Oliver Englhard

- Page 217 and 218:

1.3 A Closed Facade Area of 32 % Ad

- Page 219 and 220:

Advanced Building Skins 1.5 Closed-

- Page 221 and 222:

Advanced Building Skins Second Part

- Page 223 and 224:

Prof. Dr.nat.techn. Oliver Englhard

- Page 225 and 226:

Advanced Building Skins This assump

- Page 227 and 228:

Advanced Building Skins The require

- Page 229 and 230:

Advanced Building Skins Figure 7: T

- Page 231 and 232:

Advanced Building Skins Figure 9: I

- Page 233 and 234:

Prof. Dr.nat.techn. Oliver Englhard

- Page 235 and 236:

Advanced Building Skins Figure 3: K

- Page 237 and 238:

Advanced Building Skins Hartenaugas

- Page 239 and 240:

Prof. Dr.nat.techn. Oliver Englhard

- Page 241 and 242:

Advanced Building Skins 2.2 Determi

- Page 243 and 244:

Performance Condition Advanced Buil

- Page 245 and 246:

Advanced Building Skins 5 Cable Net

- Page 247 and 248:

5.4 Glass Clamp Connector Advanced

- Page 249 and 250:

Advanced Building Skins Figure 14:

- Page 251 and 252:

Advanced Building Skins elasto-plas

- Page 253 and 254:

Example projects include: Advanced

- Page 255 and 256:

Advanced Building Skins Figure 4: L

- Page 257 and 258:

Advanced Building Skins Language ba

- Page 259 and 260:

3 Summary and Conclusion Advanced B

- Page 261 and 262:

GENERAL PROPERTIES WEIGHT MORPHABIL

- Page 263 and 264:

Advanced Building Skins Regarding t

- Page 265 and 266:

Advanced Building Skins applied to

- Page 267 and 268:

4 Comparison Advanced Building Skin

- Page 269 and 270:

5 Conclusion Advanced Building Skin

- Page 271 and 272:

Advanced Building Skins Façades a

- Page 273 and 274:

Advanced Building Skins The deforma

- Page 275 and 276:

Advanced Building Skins In this cas

- Page 277 and 278:

Advanced Building Skins The interna

- Page 279 and 280:

Advanced Building Skins Because the

- Page 281 and 282:

Advanced Building Skins designers.

- Page 283 and 284:

Advanced Building Skins anchor poin

- Page 285 and 286:

Advanced Building Skins In a first