advanced building skins 14 | 15 June 2012 - lamp.tugraz.at - Graz ...

advanced building skins 14 | 15 June 2012 - lamp.tugraz.at - Graz ...

advanced building skins 14 | 15 June 2012 - lamp.tugraz.at - Graz ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Advanced Building Skins<br />

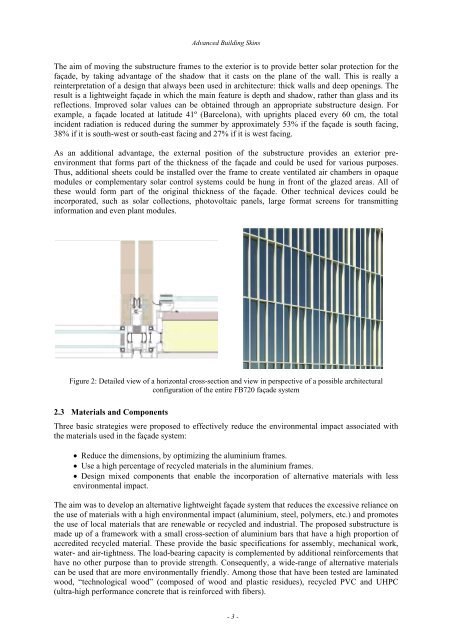

The aim of moving the substructure frames to the exterior is to provide better solar protection for the<br />

façade, by taking advantage of the shadow th<strong>at</strong> it casts on the plane of the wall. This is really a<br />

reinterpret<strong>at</strong>ion of a design th<strong>at</strong> always been used in architecture: thick walls and deep openings. The<br />

result is a lightweight façade in which the main fe<strong>at</strong>ure is depth and shadow, r<strong>at</strong>her than glass and its<br />

reflections. Improved solar values can be obtained through an appropri<strong>at</strong>e substructure design. For<br />

example, a façade loc<strong>at</strong>ed <strong>at</strong> l<strong>at</strong>itude 41º (Barcelona), with uprights placed every 60 cm, the total<br />

incident radi<strong>at</strong>ion is reduced during the summer by approxim<strong>at</strong>ely 53% if the façade is south facing,<br />

38% if it is south-west or south-east facing and 27% if it is west facing.<br />

As an additional advantage, the external position of the substructure provides an exterior preenvironment<br />

th<strong>at</strong> forms part of the thickness of the façade and could be used for various purposes.<br />

Thus, additional sheets could be installed over the frame to cre<strong>at</strong>e ventil<strong>at</strong>ed air chambers in opaque<br />

modules or complementary solar control systems could be hung in front of the glazed areas. All of<br />

these would form part of the original thickness of the façade. Other technical devices could be<br />

incorpor<strong>at</strong>ed, such as solar collections, photovoltaic panels, large form<strong>at</strong> screens for transmitting<br />

inform<strong>at</strong>ion and even plant modules.<br />

Figure 2: Detailed view of a horizontal cross-section and view in perspective of a possible architectural<br />

configur<strong>at</strong>ion of the entire FB720 façade system<br />

2.3 M<strong>at</strong>erials and Components<br />

Three basic str<strong>at</strong>egies were proposed to effectively reduce the environmental impact associ<strong>at</strong>ed with<br />

the m<strong>at</strong>erials used in the façade system:<br />

Reduce the dimensions, by optimizing the aluminium frames.<br />

Use a high percentage of recycled m<strong>at</strong>erials in the aluminium frames.<br />

Design mixed components th<strong>at</strong> enable the incorpor<strong>at</strong>ion of altern<strong>at</strong>ive m<strong>at</strong>erials with less<br />

environmental impact.<br />

The aim was to develop an altern<strong>at</strong>ive lightweight façade system th<strong>at</strong> reduces the excessive reliance on<br />

the use of m<strong>at</strong>erials with a high environmental impact (aluminium, steel, polymers, etc.) and promotes<br />

the use of local m<strong>at</strong>erials th<strong>at</strong> are renewable or recycled and industrial. The proposed substructure is<br />

made up of a framework with a small cross-section of aluminium bars th<strong>at</strong> have a high proportion of<br />

accredited recycled m<strong>at</strong>erial. These provide the basic specific<strong>at</strong>ions for assembly, mechanical work,<br />

w<strong>at</strong>er- and air-tightness. The load-bearing capacity is complemented by additional reinforcements th<strong>at</strong><br />

have no other purpose than to provide strength. Consequently, a wide-range of altern<strong>at</strong>ive m<strong>at</strong>erials<br />

can be used th<strong>at</strong> are more environmentally friendly. Among those th<strong>at</strong> have been tested are lamin<strong>at</strong>ed<br />

wood, “technological wood” (composed of wood and plastic residues), recycled PVC and UHPC<br />

(ultra-high performance concrete th<strong>at</strong> is reinforced with fibers).<br />

- 3 -