advanced building skins 14 | 15 June 2012 - lamp.tugraz.at - Graz ...

advanced building skins 14 | 15 June 2012 - lamp.tugraz.at - Graz ...

advanced building skins 14 | 15 June 2012 - lamp.tugraz.at - Graz ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Advanced Building Skins<br />

correspond to a lightweight concrete or even wood or aer<strong>at</strong>ed concrete. Fulfilling the load bearing<br />

functionality could possibly lead to an increase in density or thickness, but even so the thermal and fire<br />

retention properties would not be resolved.<br />

Thermal insul<strong>at</strong>ion and fire retention<br />

A m<strong>at</strong>erial th<strong>at</strong> is a poor conductor and is not highly combustible s<strong>at</strong>isfies the functionality of thermal<br />

insul<strong>at</strong>ion but not th<strong>at</strong> of fire retention. By increasing the thickness, it is possible to improve the<br />

response to the l<strong>at</strong>ter by slowing its loss of integrity.<br />

In this case, the thickness is conditioned by fire retention and not by thermal insul<strong>at</strong>ion.<br />

If a m<strong>at</strong>erial is sufficiently conductive, the thickness required to provide thermal insul<strong>at</strong>ion will surely<br />

be gre<strong>at</strong>er than th<strong>at</strong> needed to avoid fire propag<strong>at</strong>ion.<br />

For instance, the combustion speed (0.76 mm/min) of KLH plywood requires the use of a 117-mmthick<br />

panel to s<strong>at</strong>isfy the fire retention property. This thickness is increased to 200 mm to fulfill the<br />

required transmittance.<br />

This same thickness of aer<strong>at</strong>ed concrete is capable of withstanding fire for six hours but it barely is<br />

able to fulfill the transmittance required in the harshest clim<strong>at</strong>ic zone, E1.<br />

In combustible m<strong>at</strong>erials of a thermal conductivity of around 0.035 W/mK, th<strong>at</strong> is, all those thermal<br />

insul<strong>at</strong>ors not included in c<strong>at</strong>egory A1, the increase in thickness is justified by the m<strong>at</strong>erials’ s<strong>at</strong>isfying<br />

fire retention requirements.<br />

In a steel sandwich panel with a polyisocyanur<strong>at</strong>e (Polyiso) core, less thickness is required to s<strong>at</strong>isfy<br />

the thermal functionality (80 mm) than for s<strong>at</strong>isfying the needs for fire retention (175 mm).<br />

The combin<strong>at</strong>ion of separ<strong>at</strong>ing these two functionalities from the panel gives rise to the definition of<br />

two types th<strong>at</strong> each fulfill four functionalities, depending on whether the fourth functionality included<br />

is th<strong>at</strong> of thermal insul<strong>at</strong>ion or fire retention, respectively.<br />

5 The Morphological Diversity of Load-bearing Inner Skins of Panels<br />

5.1 Morphologies Definition<br />

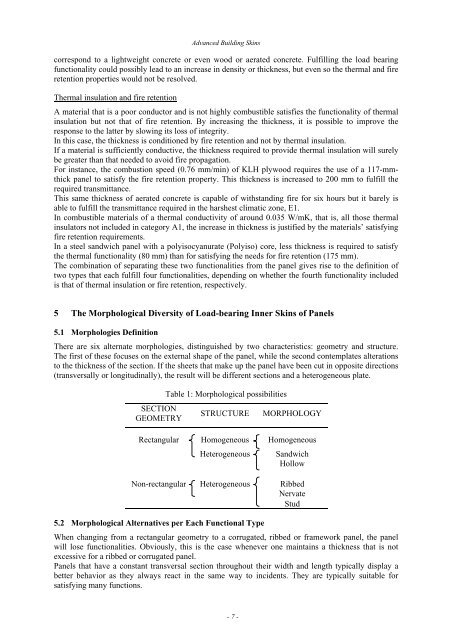

There are six altern<strong>at</strong>e morphologies, distinguished by two characteristics: geometry and structure.<br />

The first of these focuses on the external shape of the panel, while the second contempl<strong>at</strong>es alter<strong>at</strong>ions<br />

to the thickness of the section. If the sheets th<strong>at</strong> make up the panel have been cut in opposite directions<br />

(transversally or longitudinally), the result will be different sections and a heterogeneous pl<strong>at</strong>e.<br />

SECTION<br />

GEOMETRY<br />

Rectangular<br />

Table 1: Morphological possibilities<br />

STRUCTURE MORPHOLOGY<br />

Homogeneous Homogeneous<br />

Heterogeneous<br />

- 7 -<br />

Sandwich<br />

Hollow<br />

Non-rectangular Heterogeneous Ribbed<br />

Nerv<strong>at</strong>e<br />

Stud<br />

5.2 Morphological Altern<strong>at</strong>ives per Each Functional Type<br />

When changing from a rectangular geometry to a corrug<strong>at</strong>ed, ribbed or framework panel, the panel<br />

will lose functionalities. Obviously, this is the case whenever one maintains a thickness th<strong>at</strong> is not<br />

excessive for a ribbed or corrug<strong>at</strong>ed panel.<br />

Panels th<strong>at</strong> have a constant transversal section throughout their width and length typically display a<br />

better behavior as they always react in the same way to incidents. They are typically suitable for<br />

s<strong>at</strong>isfying many functions.