advanced building skins 14 | 15 June 2012 - lamp.tugraz.at - Graz ...

advanced building skins 14 | 15 June 2012 - lamp.tugraz.at - Graz ...

advanced building skins 14 | 15 June 2012 - lamp.tugraz.at - Graz ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Advanced Building Skins<br />

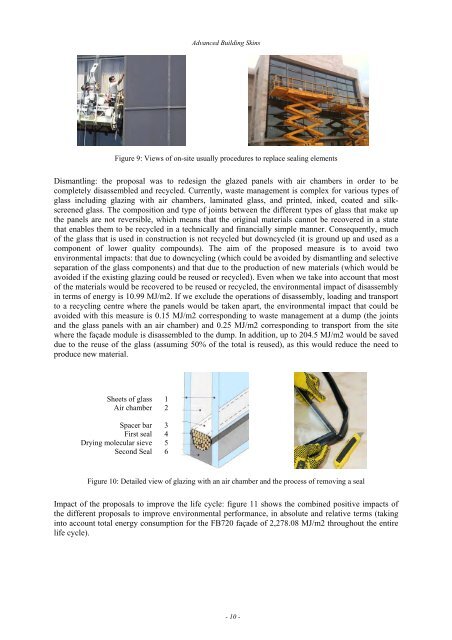

Figure 9: Views of on-site usually procedures to replace sealing elements<br />

Dismantling: the proposal was to redesign the glazed panels with air chambers in order to be<br />

completely disassembled and recycled. Currently, waste management is complex for various types of<br />

glass including glazing with air chambers, lamin<strong>at</strong>ed glass, and printed, inked, co<strong>at</strong>ed and silkscreened<br />

glass. The composition and type of joints between the different types of glass th<strong>at</strong> make up<br />

the panels are not reversible, which means th<strong>at</strong> the original m<strong>at</strong>erials cannot be recovered in a st<strong>at</strong>e<br />

th<strong>at</strong> enables them to be recycled in a technically and financially simple manner. Consequently, much<br />

of the glass th<strong>at</strong> is used in construction is not recycled but downcycled (it is ground up and used as a<br />

component of lower quality compounds). The aim of the proposed measure is to avoid two<br />

environmental impacts: th<strong>at</strong> due to downcycling (which could be avoided by dismantling and selective<br />

separ<strong>at</strong>ion of the glass components) and th<strong>at</strong> due to the production of new m<strong>at</strong>erials (which would be<br />

avoided if the existing glazing could be reused or recycled). Even when we take into account th<strong>at</strong> most<br />

of the m<strong>at</strong>erials would be recovered to be reused or recycled, the environmental impact of disassembly<br />

in terms of energy is 10.99 MJ/m2. If we exclude the oper<strong>at</strong>ions of disassembly, loading and transport<br />

to a recycling centre where the panels would be taken apart, the environmental impact th<strong>at</strong> could be<br />

avoided with this measure is 0.<strong>15</strong> MJ/m2 corresponding to waste management <strong>at</strong> a dump (the joints<br />

and the glass panels with an air chamber) and 0.25 MJ/m2 corresponding to transport from the site<br />

where the façade module is disassembled to the dump. In addition, up to 204.5 MJ/m2 would be saved<br />

due to the reuse of the glass (assuming 50% of the total is reused), as this would reduce the need to<br />

produce new m<strong>at</strong>erial.<br />

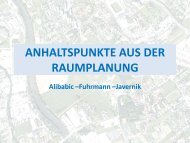

Sheets of glass<br />

Air chamber<br />

Spacer bar<br />

First seal<br />

Drying molecular sieve<br />

Second Seal<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

Figure 10: Detailed view of glazing with an air chamber and the process of removing a seal<br />

Impact of the proposals to improve the life cycle: figure 11 shows the combined positive impacts of<br />

the different proposals to improve environmental performance, in absolute and rel<strong>at</strong>ive terms (taking<br />

into account total energy consumption for the FB720 façade of 2,278.08 MJ/m2 throughout the entire<br />

life cycle).<br />

- 10 -