advanced building skins 14 | 15 June 2012 - lamp.tugraz.at - Graz ...

advanced building skins 14 | 15 June 2012 - lamp.tugraz.at - Graz ...

advanced building skins 14 | 15 June 2012 - lamp.tugraz.at - Graz ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2 Physical and Solar Properties<br />

2.1 Insul<strong>at</strong>ing Capacity<br />

Advanced Building Skins<br />

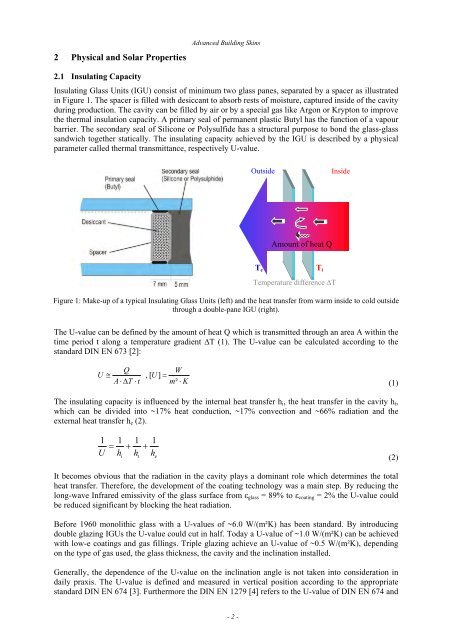

Insul<strong>at</strong>ing Glass Units (IGU) consist of minimum two glass panes, separ<strong>at</strong>ed by a spacer as illustr<strong>at</strong>ed<br />

in Figure 1. The spacer is filled with desiccant to absorb rests of moisture, captured inside of the cavity<br />

during production. The cavity can be filled by air or by a special gas like Argon or Krypton to improve<br />

the thermal insul<strong>at</strong>ion capacity. A primary seal of permanent plastic Butyl has the function of a vapour<br />

barrier. The secondary seal of Silicone or Polysulfide has a structural purpose to bond the glass-glass<br />

sandwich together st<strong>at</strong>ically. The insul<strong>at</strong>ing capacity achieved by the IGU is described by a physical<br />

parameter called thermal transmittance, respectively U-value.<br />

Figure 1: Make-up of a typical Insul<strong>at</strong>ing Glass Units (left) and the he<strong>at</strong> transfer from warm inside to cold outside<br />

through a double-pane IGU (right).<br />

The U-value can be defined by the amount of he<strong>at</strong> Q which is transmitted through an area A within the<br />

time period t along a temper<strong>at</strong>ure gradient ∆T (1). The U-value can be calcul<strong>at</strong>ed according to the<br />

standard DIN EN 673 [2]:<br />

Q<br />

U <br />

A T<br />

t<br />

W<br />

, [ U ] <br />

m²<br />

K<br />

The insul<strong>at</strong>ing capacity is influenced by the internal he<strong>at</strong> transfer hi, the he<strong>at</strong> transfer in the cavity ht,<br />

which can be divided into ~17% he<strong>at</strong> conduction, ~17% convection and ~66% radi<strong>at</strong>ion and the<br />

external he<strong>at</strong> transfer he (2).<br />

1 1 1 1<br />

<br />

U h h h<br />

i<br />

t<br />

e<br />

- 2 -<br />

Outside<br />

Amount of he<strong>at</strong> Q<br />

Te Ti<br />

Temper<strong>at</strong>ure difference ∆T<br />

Inside<br />

It becomes obvious th<strong>at</strong> the radi<strong>at</strong>ion in the cavity plays a dominant role which determines the total<br />

he<strong>at</strong> transfer. Therefore, the development of the co<strong>at</strong>ing technology was a main step. By reducing the<br />

long-wave Infrared emissivity of the glass surface from εglass = 89% to εco<strong>at</strong>ing = 2% the U-value could<br />

be reduced significant by blocking the he<strong>at</strong> radi<strong>at</strong>ion.<br />

Before 1960 monolithic glass with a U-values of ~6.0 W/(m²K) has been standard. By introducing<br />

double glazing IGUs the U-value could cut in half. Today a U-value of ~1.0 W/(m²K) can be achieved<br />

with low-e co<strong>at</strong>ings and gas fillings. Triple glazing achieve an U-value of ~0.5 W/(m²K), depending<br />

on the type of gas used, the glass thickness, the cavity and the inclin<strong>at</strong>ion installed.<br />

Generally, the dependence of the U-value on the inclin<strong>at</strong>ion angle is not taken into consider<strong>at</strong>ion in<br />

daily praxis. The U-value is defined and measured in vertical position according to the appropri<strong>at</strong>e<br />

standard DIN EN 674 [3]. Furthermore the DIN EN 1279 [4] refers to the U-value of DIN EN 674 and<br />

(1)<br />

(2)