advanced building skins 14 | 15 June 2012 - lamp.tugraz.at - Graz ...

advanced building skins 14 | 15 June 2012 - lamp.tugraz.at - Graz ...

advanced building skins 14 | 15 June 2012 - lamp.tugraz.at - Graz ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Advanced Building Skins<br />

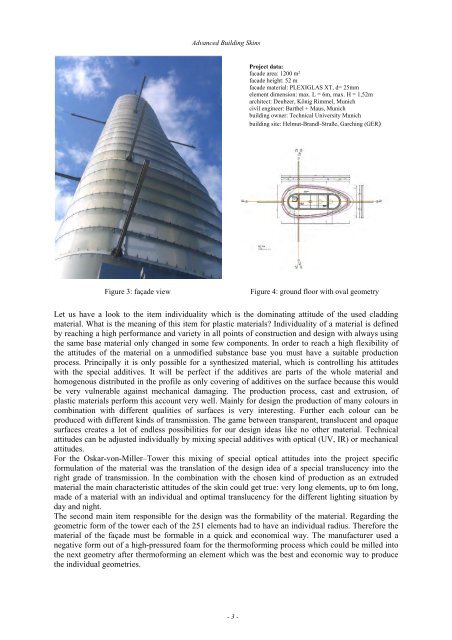

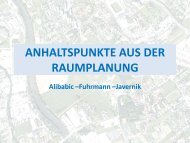

Figure 3: façade view Figure 4: ground floor with oval geometry<br />

Let us have a look to the item individuality which is the domin<strong>at</strong>ing <strong>at</strong>titude of the used cladding<br />

m<strong>at</strong>erial. Wh<strong>at</strong> is the meaning of this item for plastic m<strong>at</strong>erials? Individuality of a m<strong>at</strong>erial is defined<br />

by reaching a high performance and variety in all points of construction and design with always using<br />

the same base m<strong>at</strong>erial only changed in some few components. In order to reach a high flexibility of<br />

the <strong>at</strong>titudes of the m<strong>at</strong>erial on a unmodified substance base you must have a suitable production<br />

process. Principally it is only possible for a synthesized m<strong>at</strong>erial, which is controlling his <strong>at</strong>titudes<br />

with the special additives. It will be perfect if the additives are parts of the whole m<strong>at</strong>erial and<br />

homogenous distributed in the profile as only covering of additives on the surface because this would<br />

be very vulnerable against mechanical damaging. The production process, cast and extrusion, of<br />

plastic m<strong>at</strong>erials perform this account very well. Mainly for design the production of many colours in<br />

combin<strong>at</strong>ion with different qualities of surfaces is very interesting. Further each colour can be<br />

produced with different kinds of transmission. The game between transparent, translucent and opaque<br />

surfaces cre<strong>at</strong>es a lot of endless possibilities for our design ideas like no other m<strong>at</strong>erial. Technical<br />

<strong>at</strong>titudes can be adjusted individually by mixing special additives with optical (UV, IR) or mechanical<br />

<strong>at</strong>titudes.<br />

For the Oskar-von-Miller–Tower this mixing of special optical <strong>at</strong>titudes into the project specific<br />

formul<strong>at</strong>ion of the m<strong>at</strong>erial was the transl<strong>at</strong>ion of the design idea of a special translucency into the<br />

right grade of transmission. In the combin<strong>at</strong>ion with the chosen kind of production as an extruded<br />

m<strong>at</strong>erial the main characteristic <strong>at</strong>titudes of the skin could get true: very long elements, up to 6m long,<br />

made of a m<strong>at</strong>erial with an individual and optimal translucency for the different lighting situ<strong>at</strong>ion by<br />

day and night.<br />

The second main item responsible for the design was the formability of the m<strong>at</strong>erial. Regarding the<br />

geometric form of the tower each of the 251 elements had to have an individual radius. Therefore the<br />

m<strong>at</strong>erial of the façade must be formable in a quick and economical way. The manufacturer used a<br />

neg<strong>at</strong>ive form out of a high-pressured foam for the thermoforming process which could be milled into<br />

the next geometry after thermoforming an element which was the best and economic way to produce<br />

the individual geometries.<br />

- 3 -<br />

Project d<strong>at</strong>a:<br />

facade area: 1200 m²<br />

facade height: 52 m<br />

facade m<strong>at</strong>erial: PLEXIGLAS XT, d= 25mm<br />

element dimension: max. L = 6m, max. H = 1,52m<br />

architect: Deubzer, König Rimmel, Munich<br />

civil engineer: Barthel + Maus, Munich<br />

<strong>building</strong> owner: Technical University Munich<br />

<strong>building</strong> site: Helmut-Brandl-Straße, Garching (GER)