advanced building skins 14 | 15 June 2012 - lamp.tugraz.at - Graz ...

advanced building skins 14 | 15 June 2012 - lamp.tugraz.at - Graz ...

advanced building skins 14 | 15 June 2012 - lamp.tugraz.at - Graz ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3.2 Development of the Numerical Model<br />

Advanced Building Skins<br />

The most important task while developing the numerical model is to ensure its correct functioning.<br />

Some numerical details, for example the he<strong>at</strong> transfer from the pipe to the foam or the he<strong>at</strong> transfer<br />

from the foam to the surface, is numerical non-critical and thus in the scope of testing the single<br />

components not further investig<strong>at</strong>ed. The most challenging part of the numerical simul<strong>at</strong>ion is the he<strong>at</strong><br />

transfer from the fluid to the inner wall of the pipe. This transfer is dependent on the properties of the<br />

fluid, the velocity and the geometry. Based on a circular pipe, there are two possible ways for a<br />

numerical simul<strong>at</strong>ion. The more accur<strong>at</strong>e way is to simul<strong>at</strong>e the fluid with all its changing properties<br />

depending on its position in the pipe. Such a simul<strong>at</strong>ion leads to more realistic total values, but the<br />

simul<strong>at</strong>ion itself becomes very complex. Thus the second way, the numerical simul<strong>at</strong>ion with the<br />

abstraction, th<strong>at</strong> fluid is assumed to be uniform over the width of the pipe, is chosen. The results of the<br />

numerical simul<strong>at</strong>ion, using the simplified he<strong>at</strong> transfer from the fluid to the pipe, are proofed by using<br />

calcul<strong>at</strong>ion methods given by ‘[2]’. After combining the models of all components to cre<strong>at</strong>e a<br />

sandwich panel with an integr<strong>at</strong>ed solar system, the accuracy of the whole model is verified by the use<br />

of a constructed prototype.<br />

The prototype is a 0.5 mm thick steel sheet with a pipe system underne<strong>at</strong>h. The pipe is made of copper<br />

and has an inner diameter of 6 mm and an outer diameter of 8 mm. It is glued directly to the steel sheet.<br />

The total length of the pipe is 10.61 m. The total size of the prototypes surface is 1 m x 1 m.<br />

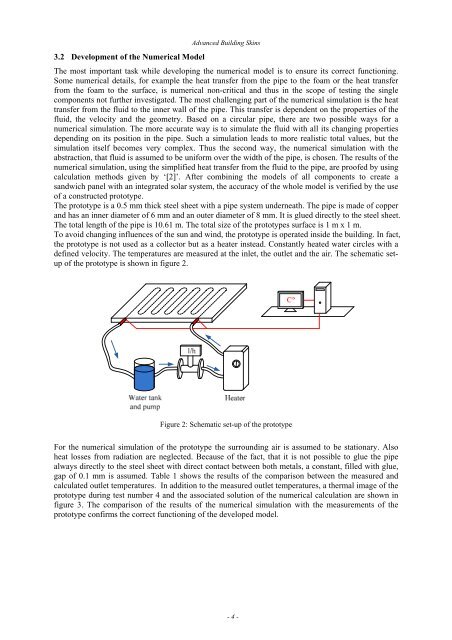

To avoid changing influences of the sun and wind, the prototype is oper<strong>at</strong>ed inside the <strong>building</strong>. In fact,<br />

the prototype is not used as a collector but as a he<strong>at</strong>er instead. Constantly he<strong>at</strong>ed w<strong>at</strong>er circles with a<br />

defined velocity. The temper<strong>at</strong>ures are measured <strong>at</strong> the inlet, the outlet and the air. The schem<strong>at</strong>ic setup<br />

of the prototype is shown in figure 2.<br />

Figure 2: Schem<strong>at</strong>ic set-up of the prototype<br />

For the numerical simul<strong>at</strong>ion of the prototype the surrounding air is assumed to be st<strong>at</strong>ionary. Also<br />

he<strong>at</strong> losses from radi<strong>at</strong>ion are neglected. Because of the fact, th<strong>at</strong> it is not possible to glue the pipe<br />

always directly to the steel sheet with direct contact between both metals, a constant, filled with glue,<br />

gap of 0.1 mm is assumed. Table 1 shows the results of the comparison between the measured and<br />

calcul<strong>at</strong>ed outlet temper<strong>at</strong>ures. In addition to the measured outlet temper<strong>at</strong>ures, a thermal image of the<br />

prototype during test number 4 and the associ<strong>at</strong>ed solution of the numerical calcul<strong>at</strong>ion are shown in<br />

figure 3. The comparison of the results of the numerical simul<strong>at</strong>ion with the measurements of the<br />

prototype confirms the correct functioning of the developed model.<br />

- 4 -