advanced building skins 14 | 15 June 2012 - lamp.tugraz.at - Graz ...

advanced building skins 14 | 15 June 2012 - lamp.tugraz.at - Graz ...

advanced building skins 14 | 15 June 2012 - lamp.tugraz.at - Graz ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

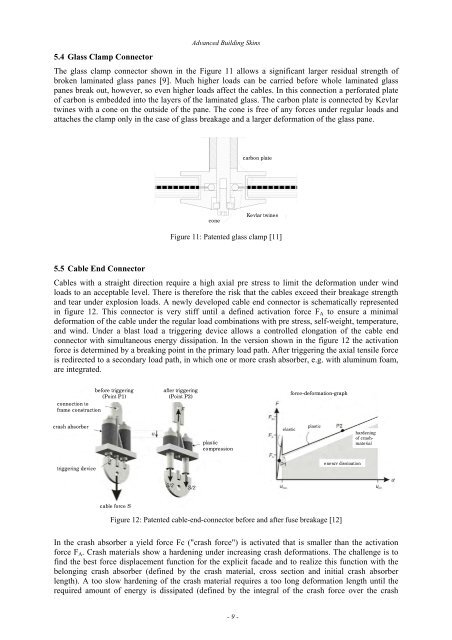

5.4 Glass C<strong>lamp</strong> Connector<br />

Advanced Building Skins<br />

The glass c<strong>lamp</strong> connector shown in the Figure 11 allows a significant larger residual strength of<br />

broken lamin<strong>at</strong>ed glass panes [9]. Much higher loads can be carried before whole lamin<strong>at</strong>ed glass<br />

panes break out, however, so even higher loads affect the cables. In this connection a perfor<strong>at</strong>ed pl<strong>at</strong>e<br />

of carbon is embedded into the layers of the lamin<strong>at</strong>ed glass. The carbon pl<strong>at</strong>e is connected by Kevlar<br />

twines with a cone on the outside of the pane. The cone is free of any forces under regular loads and<br />

<strong>at</strong>taches the c<strong>lamp</strong> only in the case of glass breakage and a larger deform<strong>at</strong>ion of the glass pane.<br />

Figure 11: P<strong>at</strong>ented glass c<strong>lamp</strong> [11]<br />

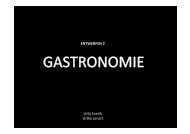

5.5 Cable End Connector<br />

Cables with a straight direction require a high axial pre stress to limit the deform<strong>at</strong>ion under wind<br />

loads to an acceptable level. There is therefore the risk th<strong>at</strong> the cables exceed their breakage strength<br />

and tear under explosion loads. A newly developed cable end connector is schem<strong>at</strong>ically represented<br />

in figure 12. This connector is very stiff until a defined activ<strong>at</strong>ion force FA to ensure a minimal<br />

deform<strong>at</strong>ion of the cable under the regular load combin<strong>at</strong>ions with pre stress, self-weight, temper<strong>at</strong>ure,<br />

and wind. Under a blast load a triggering device allows a controlled elong<strong>at</strong>ion of the cable end<br />

connector with simultaneous energy dissip<strong>at</strong>ion. In the version shown in the figure 12 the activ<strong>at</strong>ion<br />

force is determined by a breaking point in the primary load p<strong>at</strong>h. After triggering the axial tensile force<br />

is redirected to a secondary load p<strong>at</strong>h, in which one or more crash absorber, e.g. with aluminum foam,<br />

are integr<strong>at</strong>ed.<br />

before triggering<br />

(Point P1)<br />

connection to<br />

frame construction<br />

crash absorber<br />

triggering device<br />

cable force S<br />

after triggering<br />

(Point P2)<br />

cone<br />

plastic<br />

compression<br />

Figure 12: P<strong>at</strong>ented cable-end-connector before and after fuse breakage [12]<br />

In the crash absorber a yield force Fc ("crash force") is activ<strong>at</strong>ed th<strong>at</strong> is smaller than the activ<strong>at</strong>ion<br />

force FA. Crash m<strong>at</strong>erials show a hardening under increasing crash deform<strong>at</strong>ions. The challenge is to<br />

find the best force displacement function for the explicit facade and to realize this function with the<br />

belonging crash absorber (defined by the crash m<strong>at</strong>erial, cross section and initial crash absorber<br />

length). A too slow hardening of the crash m<strong>at</strong>erial requires a too long deform<strong>at</strong>ion length until the<br />

required amount of energy is dissip<strong>at</strong>ed (defined by the integral of the crash force over the crash<br />

- 9 -<br />

carbon pl<strong>at</strong>e<br />

Kevlar twines<br />

elastic<br />

force-deform<strong>at</strong>ion-graph<br />

plastic<br />

energy dissip<strong>at</strong>ion<br />

hardening<br />

of crash-<br />

m<strong>at</strong>erial