CNC 8055 - Operating manual (MC option) - Fagor Automation

CNC 8055 - Operating manual (MC option) - Fagor Automation

CNC 8055 - Operating manual (MC option) - Fagor Automation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2.<br />

OPERATING IN JOG MODE<br />

Tool calibration<br />

<strong>CNC</strong> <strong>8055</strong><br />

<strong>CNC</strong> <strong>8055</strong>i<br />

·<strong>MC</strong>· OPTION<br />

SOFT: V01.3X<br />

·64·<br />

Operation<br />

<strong>Operating</strong> <strong>manual</strong><br />

After selecting the type of part to be centered (rectangular or circular) proceed as follows:<br />

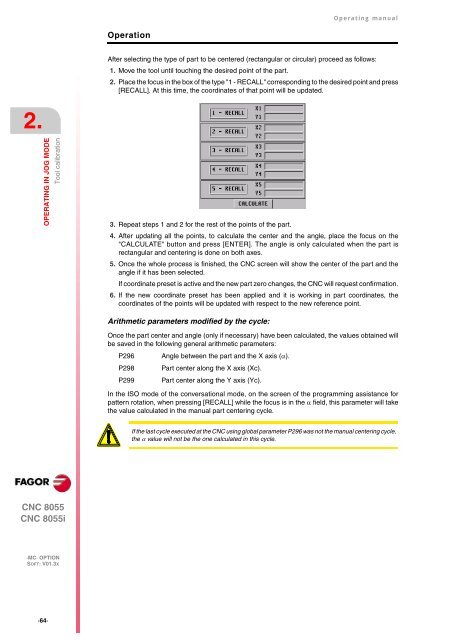

1. Move the tool until touching the desired point of the part.<br />

2. Place the focus in the box of the type "1 - RECALL" corresponding to the desired point and press<br />

[RECALL]. At this time, the coordinates of that point will be updated.<br />

3. Repeat steps 1 and 2 for the rest of the points of the part.<br />

4. After updating all the points, to calculate the center and the angle, place the focus on the<br />

"CALCULATE" button and press [ENTER]. The angle is only calculated when the part is<br />

rectangular and centering is done on both axes.<br />

5. Once the whole process is finished, the <strong>CNC</strong> screen will show the center of the part and the<br />

angle if it has been selected.<br />

If coordinate preset is active and the new part zero changes, the <strong>CNC</strong> will request confirmation.<br />

6. If the new coordinate preset has been applied and it is working in part coordinates, the<br />

coordinates of the points will be updated with respect to the new reference point.<br />

Arithmetic parameters modified by the cycle:<br />

Once the part center and angle (only if necessary) have been calculated, the values obtained will<br />

be saved in the following general arithmetic parameters:<br />

P296 Angle between the part and the X axis ().<br />

P298 Part center along the X axis (Xc).<br />

P299 Part center along the Y axis (Yc).<br />

In the ISO mode of the conversational mode, on the screen of the programming assistance for<br />

pattern rotation, when pressing [RECALL] while the focus is in the field, this parameter will take<br />

the value calculated in the <strong>manual</strong> part centering cycle.<br />

If the last cycle executed at the <strong>CNC</strong> using global parameter P296 was not the <strong>manual</strong> centering cycle,<br />

the value will not be the one calculated in this cycle.