EN: man_8065_chn.pdf - Fagor Automation

EN: man_8065_chn.pdf - Fagor Automation

EN: man_8065_chn.pdf - Fagor Automation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

7.<br />

MULTI-SPINDLE SYSTEM. SPINDLE CONTROL.<br />

CNC <strong>8065</strong><br />

(REF: 1103)<br />

·118·<br />

G96/G97. Turning speed or constant surface speed.<br />

7.3 G96/G97. Turning speed or constant surface speed.<br />

i<br />

Execution channels<br />

The following functions are oriented to lathe type machines. In order for Constant Surface Speed mode<br />

to be available, the machine <strong>man</strong>ufacturer must have set one of the axis -face axis- (parameter<br />

FACEAXIS) usually axis perpendicular to the shaft of the part. Milling type machines usually work at<br />

constant turning speed.<br />

The functions related to spindle speed programming may be used to select either Constant<br />

Surface Speed mode or Constant turning speed mode. Constant Surface Speed is only<br />

available at the master spindle of the channel.<br />

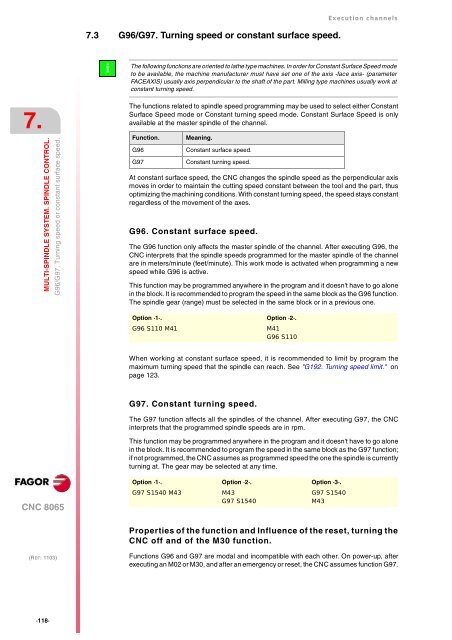

Function. Meaning.<br />

G96 Constant surface speed.<br />

G97 Constant turning speed.<br />

At constant surface speed, the CNC changes the spindle speed as the perpendicular axis<br />

moves in order to maintain the cutting speed constant between the tool and the part, thus<br />

optimizing the machining conditions. With constant turning speed, the speed stays constant<br />

regardless of the movement of the axes.<br />

G96. Constant surface speed.<br />

The G96 function only affects the master spindle of the channel. After executing G96, the<br />

CNC interprets that the spindle speeds programmed for the master spindle of the channel<br />

are in meters/minute (feet/minute). This work mode is activated when programming a new<br />

speed while G96 is active.<br />

This function may be programmed anywhere in the program and it doesn't have to go alone<br />

in the block. It is recommended to program the speed in the same block as the G96 function.<br />

The spindle gear (range) must be selected in the same block or in a previous one.<br />

Option ·1·. Option ·2·.<br />

G96 S110 M41 M41<br />

G96 S110<br />

When working at constant surface speed, it is recommended to limit by program the<br />

maximum turning speed that the spindle can reach. See "G192. Turning speed limit." on<br />

page 123.<br />

G97. Constant turning speed.<br />

The G97 function affects all the spindles of the channel. After executing G97, the CNC<br />

interprets that the programmed spindle speeds are in rpm.<br />

This function may be programmed anywhere in the program and it doesn't have to go alone<br />

in the block. It is recommended to program the speed in the same block as the G97 function;<br />

if not programmed, the CNC assumes as programmed speed the one the spindle is currently<br />

turning at. The gear may be selected at any time.<br />

Option ·1·. Option ·2·. Option ·3·.<br />

G97 S1540 M43 M43<br />

G97 S1540<br />

G97 S1540<br />

M43<br />

Properties of the function and Influence of the reset, turning the<br />

CNC off and of the M30 function.<br />

Functions G96 and G97 are modal and incompatible with each other. On power-up, after<br />

executing an M02 or M30, and after an emergency or reset, the CNC assumes function G97.