EN: man_8065_chn.pdf - Fagor Automation

EN: man_8065_chn.pdf - Fagor Automation

EN: man_8065_chn.pdf - Fagor Automation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Execution channels<br />

7.6 M41-M44. Gear change.<br />

Each spindle may have up to 4 different ranges (gears). Each gear means a speed range<br />

for the CNC work in. The programmed speed must be within the active gear; otherwise, a<br />

gear change will be required.<br />

The gear change may be automatic or <strong>man</strong>ual. When the change is <strong>man</strong>ual, the gear is<br />

selected with auxiliary functions M41 (gear 1) through M44 (gear 4). When the change is<br />

automatic, the CNC itself generates these functions according to the programmed speed.<br />

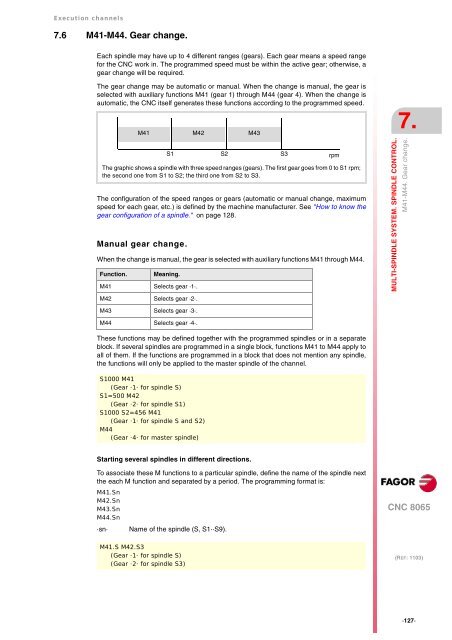

M41<br />

The graphic shows a spindle with three speed ranges (gears). The first gear goes from 0 to S1 rpm;<br />

the second one from S1 to S2; the third one from S2 to S3.<br />

The configuration of the speed ranges or gears (automatic or <strong>man</strong>ual change, maximum<br />

speed for each gear, etc.) is defined by the machine <strong>man</strong>ufacturer. See "How to know the<br />

gear configuration of a spindle." on page 128.<br />

Manual gear change.<br />

When the change is <strong>man</strong>ual, the gear is selected with auxiliary functions M41 through M44.<br />

Function. Meaning.<br />

M41 Selects gear ·1·.<br />

M42 Selects gear ·2·.<br />

M43 Selects gear ·3·.<br />

M44 Selects gear ·4·.<br />

These functions may be defined together with the programmed spindles or in a separate<br />

block. If several spindles are programmed in a single block, functions M41 to M44 apply to<br />

all of them. If the functions are programmed in a block that does not mention any spindle,<br />

the functions will only be applied to the master spindle of the channel.<br />

S1000 M41<br />

(Gear ·1· for spindle S)<br />

S1=500 M42<br />

(Gear ·2· for spindle S1)<br />

S1000 S2=456 M41<br />

(Gear ·1· for spindle S and S2)<br />

M44<br />

(Gear ·4· for master spindle)<br />

Starting several spindles in different directions.<br />

To associate these M functions to a particular spindle, define the name of the spindle next<br />

the each M function and separated by a period. The programming format is:<br />

M41.Sn<br />

M42.Sn<br />

M43.Sn<br />

M44.Sn<br />

·sn· Name of the spindle (S, S1··S9).<br />

M41.S M42.S3<br />

(Gear ·1· for spindle S)<br />

(Gear ·2· for spindle S3)<br />

M42<br />

M43<br />

S1 S2 S3<br />

rpm<br />

7.<br />

MULTI-SPINDLE SYSTEM. SPINDLE CONTROL.<br />

M41-M44. Gear change.<br />

CNC <strong>8065</strong><br />

(REF: 1103)<br />

·127·