EN: man_8065_chn.pdf - Fagor Automation

EN: man_8065_chn.pdf - Fagor Automation

EN: man_8065_chn.pdf - Fagor Automation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Execution channels<br />

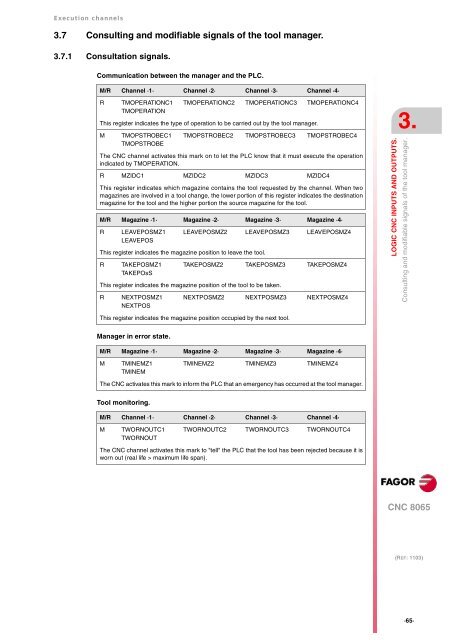

3.7 Consulting and modifiable signals of the tool <strong>man</strong>ager.<br />

3.7.1 Consultation signals.<br />

Communication between the <strong>man</strong>ager and the PLC.<br />

M/R Channel ·1· Channel ·2· Channel ·3· Channel ·4·<br />

R TMOPERATIONC1<br />

TMOPERATION<br />

Manager in error state.<br />

Tool monitoring.<br />

TMOPERATIONC2 TMOPERATIONC3 TMOPERATIONC4<br />

This register indicates the type of operation to be carried out by the tool <strong>man</strong>ager.<br />

M TMOPSTROBEC1<br />

TMOPSTROBE<br />

TMOPSTROBEC2 TMOPSTROBEC3 TMOPSTROBEC4<br />

The CNC channel activates this mark on to let the PLC know that it must execute the operation<br />

indicated by TMOPERATION.<br />

R MZIDC1 MZIDC2 MZIDC3 MZIDC4<br />

This register indicates which magazine contains the tool requested by the channel. When two<br />

magazines are involved in a tool change, the lower portion of this register indicates the destination<br />

magazine for the tool and the higher portion the source magazine for the tool.<br />

M/R Magazine ·1· Magazine ·2· Magazine ·3· Magazine ·4·<br />

R LEAVEPOSMZ1<br />

LEAVEPOS<br />

This register indicates the magazine position to leave the tool.<br />

R TAKEPOSMZ1<br />

TAKEPOsS<br />

LEAVEPOSMZ2 LEAVEPOSMZ3 LEAVEPOSMZ4<br />

TAKEPOSMZ2 TAKEPOSMZ3 TAKEPOSMZ4<br />

This register indicates the magazine position of the tool to be taken.<br />

R NEXTPOSMZ1<br />

NEXTPOS<br />

NEXTPOSMZ2 NEXTPOSMZ3 NEXTPOSMZ4<br />

This register indicates the magazine position occupied by the next tool.<br />

M/R Magazine ·1· Magazine ·2· Magazine ·3· Magazine ·4·<br />

M TMINEMZ1<br />

TMINEM<br />

TMINEMZ2 TMINEMZ3 TMINEMZ4<br />

The CNC activates this mark to inform the PLC that an emergency has occurred at the tool <strong>man</strong>ager.<br />

M/R Channel ·1· Channel ·2· Channel ·3· Channel ·4·<br />

M TWORNOUTC1<br />

TWORNOUT<br />

TWORNOUTC2 TWORNOUTC3 TWORNOUTC4<br />

The CNC channel activates this mark to "tell" the PLC that the tool has been rejected because it is<br />

worn out (real life > maximum life span).<br />

3.<br />

LOGIC CNC INPUTS AND OUTPUTS.<br />

Consulting and modifiable signals of the tool <strong>man</strong>ager.<br />

CNC <strong>8065</strong><br />

(REF: 1103)<br />

·65·