EN: man_8065_chn.pdf - Fagor Automation

EN: man_8065_chn.pdf - Fagor Automation

EN: man_8065_chn.pdf - Fagor Automation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

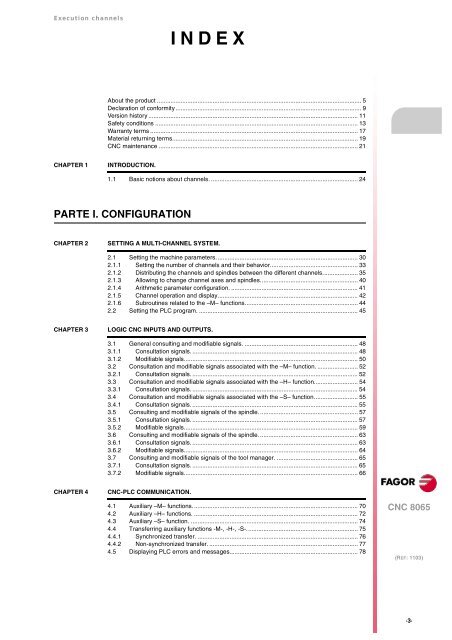

Execution channels<br />

CHAPTER 1 INTRODUCTION.<br />

INDEX<br />

About the product ......................................................................................................................... 5<br />

Declaration of conformity .............................................................................................................. 9<br />

Version history ............................................................................................................................ 11<br />

Safety conditions ........................................................................................................................ 13<br />

Warranty terms ........................................................................................................................... 17<br />

Material returning terms.............................................................................................................. 19<br />

CNC maintenance ...................................................................................................................... 21<br />

1.1 Basic notions about channels. ....................................................................................... 24<br />

PARTE I. CONFIGURATION<br />

CHAPTER 2 SETTING A MULTI-CHANNEL SYSTEM.<br />

2.1 Setting the machine parameters.................................................................................... 30<br />

2.1.1 Setting the number of channels and their behavior.................................................... 33<br />

2.1.2 Distributing the channels and spindles between the different channels..................... 35<br />

2.1.3 Allowing to change channel axes and spindles.......................................................... 40<br />

2.1.4 Arithmetic parameter configuration. ........................................................................... 41<br />

2.1.5 Channel operation and display................................................................................... 42<br />

2.1.6 Subroutines related to the –M– functions................................................................... 44<br />

2.2 Setting the PLC program. .............................................................................................. 45<br />

CHAPTER 3 LOGIC CNC INPUTS AND OUTPUTS.<br />

3.1 General consulting and modifiable signals. ................................................................... 48<br />

3.1.1 Consultation signals. .................................................................................................. 48<br />

3.1.2 Modifiable signals....................................................................................................... 50<br />

3.2 Consultation and modifiable signals associated with the –M– function. ........................ 52<br />

3.2.1 Consultation signals. .................................................................................................. 52<br />

3.3 Consultation and modifiable signals associated with the –H– function.......................... 54<br />

3.3.1 Consultation signals. .................................................................................................. 54<br />

3.4 Consultation and modifiable signals associated with the –S– function.......................... 55<br />

3.4.1 Consultation signals. .................................................................................................. 55<br />

3.5 Consulting and modifiable signals of the spindle. .......................................................... 57<br />

3.5.1 Consultation signals. .................................................................................................. 57<br />

3.5.2 Modifiable signals....................................................................................................... 59<br />

3.6 Consulting and modifiable signals of the spindle. .......................................................... 63<br />

3.6.1 Consultation signals. .................................................................................................. 63<br />

3.6.2 Modifiable signals....................................................................................................... 64<br />

3.7 Consulting and modifiable signals of the tool <strong>man</strong>ager. ................................................ 65<br />

3.7.1 Consultation signals. .................................................................................................. 65<br />

3.7.2 Modifiable signals....................................................................................................... 66<br />

CHAPTER 4 CNC-PLC COMMUNICATION.<br />

4.1 Auxiliary –M– functions.................................................................................................. 70<br />

4.2 Auxiliary –H– functions. ................................................................................................. 72<br />

4.3 Auxiliary –S– function. ................................................................................................... 74<br />

4.4 Transferring auxiliary functions -M-, -H-, -S-.................................................................. 75<br />

4.4.1 Synchronized transfer. ............................................................................................... 76<br />

4.4.2 Non-synchronized transfer. ........................................................................................ 77<br />

4.5 Displaying PLC errors and messages............................................................................ 78<br />

CNC <strong>8065</strong><br />

(REF: 1103)<br />

·3·