EN: man_8065_chn.pdf - Fagor Automation

EN: man_8065_chn.pdf - Fagor Automation

EN: man_8065_chn.pdf - Fagor Automation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

4.<br />

CNC-PLC COMMUNICATION.<br />

CNC <strong>8065</strong><br />

(REF: 1103)<br />

·74·<br />

Auxiliary –S– function.<br />

4.3 Auxiliary –S– function.<br />

Execution channels<br />

The auxiliary S function indicates the spindle turning speed with M03 and M04 or the angular<br />

position with M19. All the spindles of a channel may be controlled independently; in other<br />

words, each spindle may be given a different com<strong>man</strong>d.<br />

When using channels, the spindles may be distributed indistinctly between them. In this case,<br />

a channel can control a spindle of another channel. The marks and registers refer to the<br />

spindle regardless of the channel they belong to.<br />

Registers used in the communication between the channels and<br />

the PLC.<br />

The CNC indicates to the PLC which S functions are programmed in the execution block<br />

using 32-bit registers SFUN1 through SFUN4. These registers refer to the spindle number;<br />

they are independent from the channel where the spindle is. The spindle number is<br />

determined by its logic number that is set by the order they were defined in the machine<br />

parameter SPDLNAME.<br />

SFUN1 First spindle.<br />

SFUN2 Second spindle.<br />

SFUN3 Third spindle.<br />

SFUN4 Fourth spindle.<br />

Each one of them indicates the value of one of the S functions programmed. If all the registers<br />

are not used, the CNC assigns $FFFFFFFF to the unused ones (those with the highest<br />

numbers).<br />

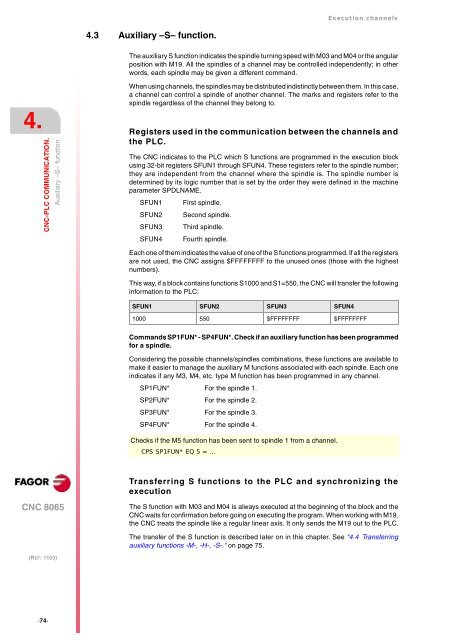

This way, if a block contains functions S1000 and S1=550, the CNC will transfer the following<br />

information to the PLC:<br />

SFUN1 SFUN2 SFUN3 SFUN4<br />

1000 550 $FFFFFFFF $FFFFFFFF<br />

Com<strong>man</strong>ds SP1FUN* - SP4FUN*. Check if an auxiliary function has been programmed<br />

for a spindle.<br />

Considering the possible channels/spindles combinations, these functions are available to<br />

make it easier to <strong>man</strong>age the auxiliary M functions associated with each spindle. Each one<br />

indicates if any M3, M4, etc. type M function has been programmed in any channel.<br />

SP1FUN* For the spindle 1.<br />

SP2FUN* For the spindle 2.<br />

SP3FUN* For the spindle 3.<br />

SP4FUN* For the spindle 4.<br />

Checks if the M5 function has been sent to spindle 1 from a channel.<br />

CPS SP1FUN* EQ 5 = ...<br />

Transferring S functions to the PLC and synchronizing the<br />

execution<br />

The S function with M03 and M04 is always executed at the beginning of the block and the<br />

CNC waits for confirmation before going on executing the program. When working with M19,<br />

the CNC treats the spindle like a regular linear axis. It only sends the M19 out to the PLC.<br />

The transfer of the S function is described later on in this chapter. See "4.4 Transferring<br />

auxiliary functions -M-, -H-, -S-." on page 75.