EN: man_8065_chn.pdf - Fagor Automation

EN: man_8065_chn.pdf - Fagor Automation

EN: man_8065_chn.pdf - Fagor Automation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2.<br />

SETTING A MULTI-CHANNEL SYSTEM.<br />

CNC <strong>8065</strong><br />

(REF: 1103)<br />

·44·<br />

Setting the machine parameters.<br />

2.1.6 Subroutines related to the –M– functions.<br />

i<br />

The following parameters correspond to the –M– function table.<br />

MPROGNAME<br />

Name of subroutine associated with M function.<br />

Possible values: any text with up to 64 characters.<br />

Default value: Without subroutine.<br />

Associated variable: (V.)MPM.MPROGNAME[pos]<br />

Parameter included in the DATA table.<br />

Execution channels<br />

The subroutines associated with the M functions must be located in the "C:\CNC8070 \MTB<br />

\SUB" folder.<br />

When associating a subroutine with an M function, the execution of the M function executes<br />

the associated subroutine without executing the M function itself. To send the M function to<br />

the PLC, it must be programmed in the subroutine.<br />

The type of synchronization of the M functions that have an associated subroutine must be<br />

"without synchronization" or "After-After". The CNC executes the associated subroutine after<br />

executing the programmed movement (if any).<br />

To have different procedures in the subroutines associated with certain M functions, the code of each<br />

channel may be differentiated within the subroutine using the variable (V.)G.CNCHANNEL..<br />

SYNCHTYPE<br />

Type of synchronization.<br />

Possible values: Without synchronization / Before-Before / Before-After / After-After.<br />

Default value: Before - Before.<br />

Associated variable: (V.)MPM.SYNCHTYPE[pos]<br />

Parameter included in the DATA table.<br />

Since the M functions may be programmed together with the movement of the axes, in the<br />

same block, it must be indicated when the function is to be sent out to the PLC and when<br />

it will be checked that it has been already executed (synchronization).<br />

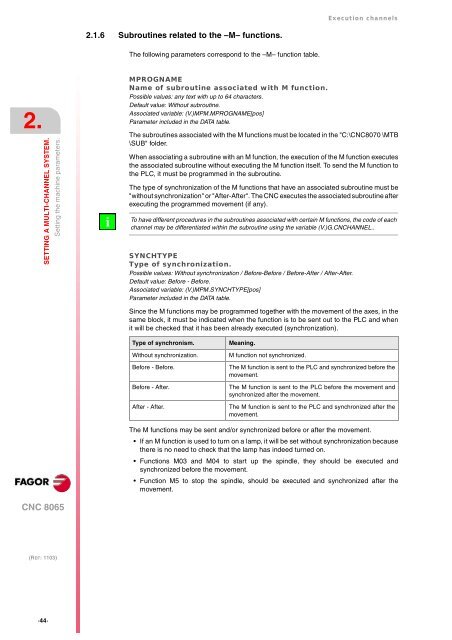

Type of synchronism. Meaning.<br />

Without synchronization. M function not synchronized.<br />

Before - Before. The M function is sent to the PLC and synchronized before the<br />

movement.<br />

Before - After. The M function is sent to the PLC before the movement and<br />

synchronized after the movement.<br />

After - After. The M function is sent to the PLC and synchronized after the<br />

movement.<br />

The M functions may be sent and/or synchronized before or after the movement.<br />

If an M function is used to turn on a lamp, it will be set without synchronization because<br />

there is no need to check that the lamp has indeed turned on.<br />

Functions M03 and M04 to start up the spindle, they should be executed and<br />

synchronized before the movement.<br />

Function M5 to stop the spindle, should be executed and synchronized after the<br />

movement.