1928 Cadillac - GM Heritage Center

1928 Cadillac - GM Heritage Center

1928 Cadillac - GM Heritage Center

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

56 C A D I L L A C 0 P E R A T O R ' S MANUAL<br />

Generator Oil Cups; 12<br />

Two oil cups on the generator conduct lubricant to the forward and rear<br />

bearings on the armature shaft. A few drops of engine oil should be applied<br />

to each cup every 1000 miles.<br />

Timer-Distributor Oil Cup; 5<br />

The oil cup at "5" is for lubricating the ball bearing at the upper end of<br />

the timer-distributor shaft. A few drops of engine oil should be applied<br />

every 1000 miles.<br />

Fan; 7<br />

The fan is lubricated by oil contained in a reservoir in the fan hub. The<br />

screw plug in the outside of the reservoir should be removed every 1000<br />

miles and engine oil should be added to bring the oil to the proper level. In<br />

adding oil, it is necessary to add somewhat more than enough and then<br />

drain off the surplus by turning the fan so that the hole points down. A<br />

short stand-pipe inside the reservoir insures that the proper amount of oil is<br />

retained. The filling hole should be pointed down for at least half a minute<br />

to allow air to enter and permit the surplus oil to flow out. A cloth or<br />

piece of waste may be held under the hole to catch the oil. Do not put grease<br />

or heavy oil in the fan.<br />

Water Pump; 8<br />

A grease cup is provided for lubricating the water pump. This cup should<br />

be turned down and refilled with cup grease every 1000 miles.<br />

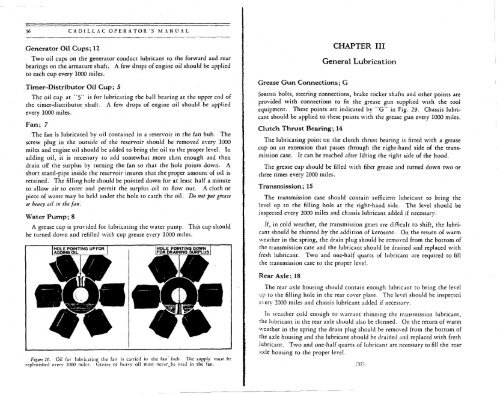

Figure 1$. Oil for lubricating the fan is carried in the fan hub. The supply must be<br />

replenished everv 1000 miles. Grease or heavy oil must never^be used in the fan.<br />

Grease Gun Connections; G<br />

CHAPTER III<br />

General Lubrication<br />

SPRING bolts, steering connections, brake rocker shafts and other points are<br />

provided with connections to fit the grease gun supplied with the tool<br />

equipment. These points are indicated by "G" in Fig. 29. Chassis lubricant<br />

should be applied to these points with the grease gun every 1000 miles.<br />

Clutch Thrust Bearing; 14<br />

The lubricating point on the clutch thrust bearing is fitted with a grease<br />

cup on an extension that passes through the right-hand side of the transmission<br />

case. It can be reached after lifting the right side of the hood.<br />

The grease cup should be filled with fiber grease and turned down two or<br />

three times every 2000 miles.<br />

Transmission; 15<br />

The transmission case should contain sufficient lubricant to bring the<br />

level up to the filling hole at the right-hand side. The level should be<br />

inspected every 2000 miles and chassis lubricant added if necessary.<br />

If, in cold weather, the transmission gears are difficult to shift, the lubricant<br />

should be thinned by the addition of kerosene. On the return of warm<br />

weather in the spring, the drain plug should be removed from the bottom of<br />

the transmission case and the lubricant should be drained and replaced with<br />

fresh lubricant. Two and one-half quarts of lubricant are required to fill<br />

the transmission case to the proper level.<br />

Rear Axle; 18<br />

The rear axle housing should contain enough lubricant to bring the level<br />

up to the filling hole in the rear cover plate. The level should be inspected<br />

every 2000 miles and chassis lubricant added if necessary.<br />

In weather cold enough to warrant thinning the transmission lubricant,<br />

the lubricant in the rear axle should also be thinned. On the return of warm<br />

weather in the spring the drain plug should be removed from the bottom of<br />

the axle housing and the lubricant should be drained and replaced with fresh<br />

lubricant. Two and one-half quarts of lubricant are necessary to fill the rear<br />

axle housing to the proper level.<br />

(57)