1928 Cadillac - GM Heritage Center

1928 Cadillac - GM Heritage Center

1928 Cadillac - GM Heritage Center

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

104 CADILLAC OPERATOR'S MANUAL<br />

^^<br />

a 1<br />

r<br />

J<br />

^dl^^H<br />

With a hammer disengage the lug<br />

that locks the ends of the rim together.<br />

Then apply the rim tool, which is included<br />

in the tool equipment. This is<br />

done by hooking the U-shaped member<br />

over the lug next to the valve stem, and<br />

inserting the bolt through the holes in<br />

the lug on the other side of the split in<br />

the rim.<br />

GENERAL INFORMATION 105<br />

Caution in Adjusting Wheel Bearings<br />

The adjustment of wheel bearings or the removal of the wheels should<br />

not be attempted by one unfamiliar with work of this nature. It is recommended<br />

that the car be taken to a <strong>Cadillac</strong> service station if possible. In<br />

any event great care must be exercised in adjusting wheel bearings not to<br />

get them tight. These bearings will revolve even when adjusted very tightly,<br />

but that condition is sure to prove disastrous. They should be adjusted so<br />

that a very slight amount of play or looseness may be discerned.<br />

If, after a bearing has been adjusted to a point that is apparently correct,<br />

the locking device cannot be placed in position without changing the adjustment,<br />

it is far better to loosen the adjustment until it can be secured with the<br />

locking device than to tighten the bearing adjustment.<br />

Pull the handle of the tool up and<br />

over as far as will go, thus drawing the<br />

one end of the rim up over the other.<br />

Figure 57.<br />

The locking tongue can then be<br />

placed back of the rivet as shown, and<br />

will hold the rim in the split position.<br />

The tire can then be forced off the<br />

rim, using the "screw-driver" end of the<br />

brace wrench.<br />

After re-installing the tire, grasp the<br />

handle of the tool, disengage the locking<br />

tongue and allow the rim to return slowly<br />

to position. After removing the tool, be<br />

sure to drive the locking lug back into<br />

place.<br />

Removing tire from rim.<br />

Removing Front Wheel<br />

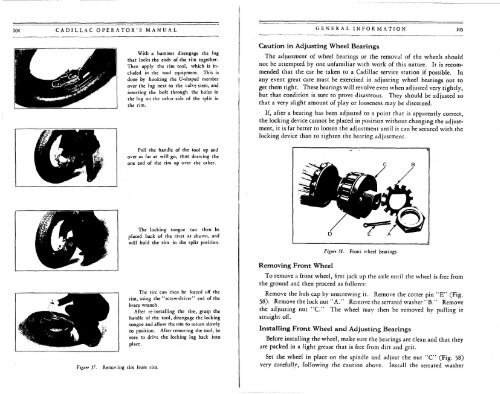

Figure 58. Front wheel bearings<br />

To remove a front wheel, first jack up the axle until the wheel is free from<br />

the ground and then proceed as follows:<br />

Remove the hub cap by unscrewing it. Remove the cotter pin "E" (Fig.<br />

58). Remove the lock nut "A." Remove the serrated washer "B." Remove<br />

the adjusting nut "C." The wheel may then be removed by pulling it<br />

straight off.<br />

Installing Front Wheel and Adjusting Bearings<br />

Before installing the wheel, make sure the bearings are clean and that they<br />

are packed in a light grease that is free from dirt and grit.<br />

Set the wheel in place on the spindle and adjust the nut "C" (Fig. 58)<br />

very carefully, following the caution above. Install the serrated washer