1928 Cadillac - GM Heritage Center

1928 Cadillac - GM Heritage Center

1928 Cadillac - GM Heritage Center

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

96 C A DILL A COPER A TOR'S MANUAL<br />

GENERAL INFORMATION 97<br />

Transmission<br />

The purpose of the transmission is to provide a means for varying the ratio<br />

and direction of the rear axle speed in relation to the engine speed. Three<br />

things are accomplished by doing this: First, the engine is enabled to drive<br />

The <strong>Cadillac</strong> transmission is known as the selective, sliding gear type. It<br />

has three speeds forward, of which one is direct drive, and one speed in<br />

reverse. Selection of the various speeds is accomplished by movement of<br />

two shifter gears (Fig. 50), which are controlled by the transmission control<br />

lever. The positions of the gears corresponding to the five positions of the<br />

control lever, as illustrated in Fig. 7, are as follow:<br />

Neutral—When the control lever is in neutral position, the shifter gears<br />

are in the positions shown in Fig. 50, that is, they are not in mesh with any<br />

of the other gears.<br />

Low—When the control lever is moved from neutral to low, the low and<br />

reverse shifter gear is moved forward into mesh with the low gear on the<br />

jack-shaft. The ratio of engine speed to propeller shaft speed in low is<br />

approximately 3 to 1.<br />

Intermediate—When the control lever is moved from low to intermediate,<br />

the low and reverse shifter gear is first returned to its neutral position and<br />

the high and intermediate shifter gear is then moved back into mesh with<br />

the intermediate gear on the jackshaft. The ratio of engine speed to propeller<br />

shaft speed in intermediate is approximately 1.7 to 1.<br />

High—When the control lever is moved from intermediate to high, the<br />

high and intermediate gear is first moved forward out of mesh with the<br />

intermediate gear on the jackshaft, and then farther forward until teeth,<br />

cut internally in a recess in the high and intermediate shifter gear, engage<br />

teeth on the extreme end of the gear on the clutch shaft. The drive is then<br />

direct from the clutch shaft to the transmission main shaft without reduction.<br />

Reverse—When the control lever is moved from neutral to reverse, the low<br />

and reverse shifter gear is moved back into mesh with an idler gear, which<br />

is at all times in mesh with the reverse gear on the jackshaft. The interposi •<br />

tion of the idler gear reverses the direction of rotation. The ratio of engine<br />

speed to propeller shaft speed in reverse is approximately 3-7 to 1.<br />

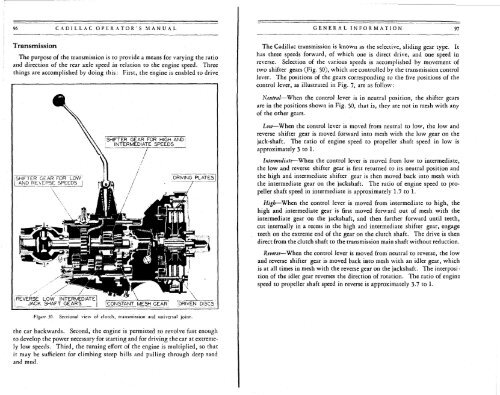

Fiptrt 50.<br />

Sectional view of clutch, transmission and universal joint.<br />

the car backwards. Second, the engine is permitted to revolve fast enough<br />

to develop the power necessary for starting and for driving the car at extremely<br />

low speeds. Third, the turning effort of the engine is multiplied, so that<br />

it may be sufficient for climbing steep hills and pulling through deep sand<br />

and mud.