DSLBD Office Fit Out - Broughton Construction Company

DSLBD Office Fit Out - Broughton Construction Company

DSLBD Office Fit Out - Broughton Construction Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

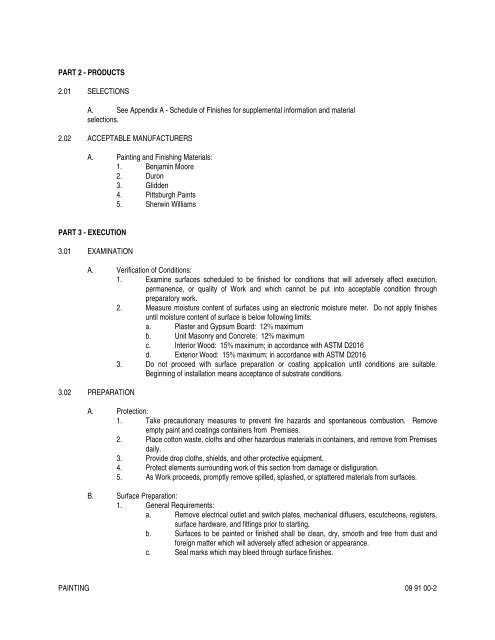

PART 2 - PRODUCTS<br />

2.01 SELECTIONS<br />

A. See Appendix A - Schedule of Finishes for supplemental information and material<br />

selections.<br />

2.02 ACCEPTABLE MANUFACTURERS<br />

A. Painting and Finishing Materials:<br />

1. Benjamin Moore<br />

2. Duron<br />

3. Glidden<br />

4. Pittsburgh Paints<br />

5. Sherwin Williams<br />

PART 3 - EXECUTION<br />

3.01 EXAMINATION<br />

A. Verification of Conditions:<br />

1. Examine surfaces scheduled to be finished for conditions that will adversely affect execution,<br />

permanence, or quality of Work and which cannot be put into acceptable condition through<br />

preparatory work.<br />

2. Measure moisture content of surfaces using an electronic moisture meter. Do not apply finishes<br />

until moisture content of surface is below following limits:<br />

a. Plaster and Gypsum Board: 12% maximum<br />

b. Unit Masonry and Concrete: 12% maximum<br />

c. Interior Wood: 15% maximum; in accordance with ASTM D2016<br />

d. Exterior Wood: 15% maximum; in accordance with ASTM D2016<br />

3. Do not proceed with surface preparation or coating application until conditions are suitable.<br />

Beginning of installation means acceptance of substrate conditions.<br />

3.02 PREPARATION<br />

A. Protection:<br />

1. Take precautionary measures to prevent fire hazards and spontaneous combustion. Remove<br />

empty paint and coatings containers from Premises.<br />

2. Place cotton waste, cloths and other hazardous materials in containers, and remove from Premises<br />

daily.<br />

3. Provide drop cloths, shields, and other protective equipment.<br />

4. Protect elements surrounding work of this section from damage or disfiguration.<br />

5. As Work proceeds, promptly remove spilled, splashed, or splattered materials from surfaces.<br />

B. Surface Preparation:<br />

1. General Requirements:<br />

a. Remove electrical outlet and switch plates, mechanical diffusers, escutcheons, registers,<br />

surface hardware, and fittings prior to starting.<br />

b. Surfaces to be painted or finished shall be clean, dry, smooth and free from dust and<br />

foreign matter which will adversely affect adhesion or appearance.<br />

c. Seal marks which may bleed through surface finishes.<br />

PAINTING 09 91 00-2