DSLBD Office Fit Out - Broughton Construction Company

DSLBD Office Fit Out - Broughton Construction Company

DSLBD Office Fit Out - Broughton Construction Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

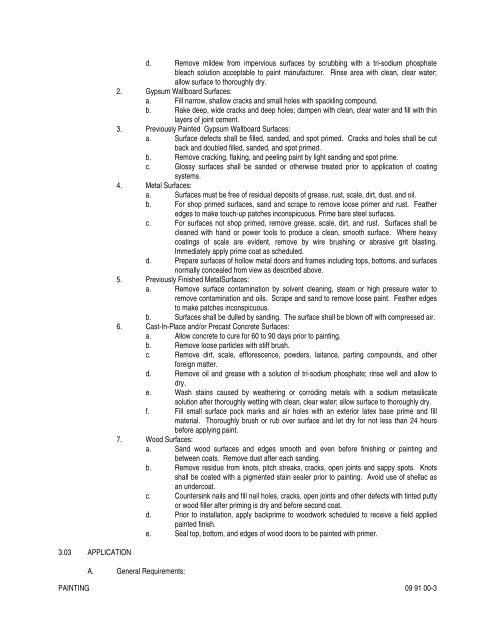

3.03 APPLICATION<br />

d. Remove mildew from impervious surfaces by scrubbing with a tri-sodium phosphate<br />

bleach solution acceptable to paint manufacturer. Rinse area with clean, clear water;<br />

allow surface to thoroughly dry.<br />

2. Gypsum Wallboard Surfaces:<br />

a. Fill narrow, shallow cracks and small holes with spackling compound.<br />

b. Rake deep, wide cracks and deep holes; dampen with clean, clear water and fill with thin<br />

layers of joint cement.<br />

3. Previously Painted Gypsum Wallboard Surfaces:<br />

a. Surface defects shall be filled, sanded, and spot primed. Cracks and holes shall be cut<br />

back and doubled filled, sanded, and spot primed.<br />

b. Remove cracking, flaking, and peeling paint by light sanding and spot prime.<br />

c. Glossy surfaces shall be sanded or otherwise treated prior to application of coating<br />

systems.<br />

4. Metal Surfaces:<br />

a. Surfaces must be free of residual deposits of grease, rust, scale, dirt, dust, and oil.<br />

b. For shop primed surfaces, sand and scrape to remove loose primer and rust. Feather<br />

edges to make touch-up patches inconspicuous. Prime bare steel surfaces.<br />

c. For surfaces not shop primed, remove grease, scale, dirt, and rust. Surfaces shall be<br />

cleaned with hand or power tools to produce a clean, smooth surface. Where heavy<br />

coatings of scale are evident, remove by wire brushing or abrasive grit blasting.<br />

Immediately apply prime coat as scheduled.<br />

d. Prepare surfaces of hollow metal doors and frames including tops, bottoms, and surfaces<br />

normally concealed from view as described above.<br />

5. Previously Finished MetalSurfaces:<br />

a. Remove surface contamination by solvent cleaning, steam or high pressure water to<br />

remove contamination and oils. Scrape and sand to remove loose paint. Feather edges<br />

to make patches inconspicuous.<br />

b. Surfaces shall be dulled by sanding. The surface shall be blown off with compressed air.<br />

6. Cast-In-Place and/or Precast Concrete Surfaces:<br />

a. Allow concrete to cure for 60 to 90 days prior to painting.<br />

b. Remove loose particles with stiff brush.<br />

c. Remove dirt, scale, efflorescence, powders, laitance, parting compounds, and other<br />

foreign matter.<br />

d. Remove oil and grease with a solution of tri-sodium phosphate; rinse well and allow to<br />

dry.<br />

e. Wash stains caused by weathering or corroding metals with a sodium metasilicate<br />

solution after thoroughly wetting with clean, clear water; allow surface to thoroughly dry.<br />

f. Fill small surface pock marks and air holes with an exterior latex base prime and fill<br />

material. Thoroughly brush or rub over surface and let dry for not less than 24 hours<br />

before applying paint.<br />

7. Wood Surfaces:<br />

a. Sand wood surfaces and edges smooth and even before finishing or painting and<br />

between coats. Remove dust after each sanding.<br />

b. Remove residue from knots, pitch streaks, cracks, open joints and sappy spots. Knots<br />

shall be coated with a pigmented stain sealer prior to painting. Avoid use of shellac as<br />

an undercoat.<br />

c. Countersink nails and fill nail holes, cracks, open joints and other defects with tinted putty<br />

or wood filler after priming is dry and before second coat.<br />

d. Prior to installation, apply backprime to woodwork scheduled to receive a field applied<br />

painted finish.<br />

e. Seal top, bottom, and edges of wood doors to be painted with primer.<br />

A. General Requirements:<br />

PAINTING 09 91 00-3