Security Assistance; and Logistics - Federation of American Scientists

Security Assistance; and Logistics - Federation of American Scientists

Security Assistance; and Logistics - Federation of American Scientists

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

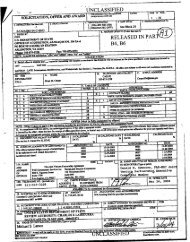

• Delivery <strong>of</strong> all parts from Taji Central Warehouse to all other Location Comm<strong>and</strong>3rd Line shopsAt the end <strong>of</strong> November 2008, the de-scoped contract was planned to end with the IraqiArmy assuming full responsibility for all 3 rd Line vehicle maintenance <strong>and</strong> Class IXMateriel Management.Materiel Management ChallengesThe transition <strong>of</strong> materiel management to Iraqi control <strong>and</strong> management was not withoutpotential impediments. Chief among these were:• The sheer number <strong>of</strong> parts required to support a diverse <strong>and</strong> non-st<strong>and</strong>ardinventory <strong>of</strong> major equipment such as that existing in the Iraqi Army• A deficiency <strong>of</strong> Iraqi Army logistics personnel appropriately trained in materielmanagement• Immature <strong>and</strong> unconnected (non-networked) information technology systemssupporting parts managementDiverse Parts InventoryOne <strong>of</strong> the most difficult problems with providing parts support for vehicle maintenancein the Iraqi Army was the fact that the IA has over 160 different types <strong>of</strong> vehicles in itsinventory. The national maintenance contractor – Anham – maintained an AuthorizedStockage List <strong>of</strong> over 6000 parts for 120 vehicle types. For some vehicles, a m<strong>and</strong>atoryparts list had not been developed.Obtaining parts for many <strong>of</strong> the vehicles that had been donated to the Iraqi Army hasbeen a near impossibility. The variation <strong>of</strong> vehicle type <strong>and</strong> their dispersion throughoutIraq caused both a lag in the requisition <strong>and</strong> distribution <strong>of</strong> parts, as well as a problemmaintaining an adequate supply <strong>of</strong> frequently used parts for required maintenance. It hadbeen difficult to position repair parts at the correct location. As the Iraqi Army hasgrown, logisticians have had to determine which parts (<strong>and</strong> how many) should beavailable for 1 st <strong>and</strong> 2 nd Line maintenance at the organizational level, <strong>and</strong> which partsshould be held at the Location Comm<strong>and</strong>s for 3 rd Line (intermediate or depot level)maintenance.In addition to the quantity <strong>and</strong> diversity <strong>of</strong> spare parts required was a coinciding problem<strong>of</strong> lack <strong>of</strong> st<strong>and</strong>ardized stock numbering. A senior <strong>of</strong>ficial in the Joint Headquartersopined that there was no concept <strong>of</strong> st<strong>and</strong>ardization for vehicle parts. He further statedthat “most <strong>of</strong> the vehicles are a liability since they cannot be supported with skilledmaintenance <strong>and</strong> parts.” It is worth noting that the Coalition in Afghanistan had beenworking to move the Afghan National Army into a system that used NATO stocknumbering.The NATO Codification System represents a uniquely reliable system for creating thest<strong>and</strong>ardized descriptions that are critical in managing a large distributed inventory <strong>and</strong>an efficient supply chain. The Assessment Team believes that the Coalition should117