Economic Assessment of Sanitation Interventions in Vietnam - WSP

Economic Assessment of Sanitation Interventions in Vietnam - WSP

Economic Assessment of Sanitation Interventions in Vietnam - WSP

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

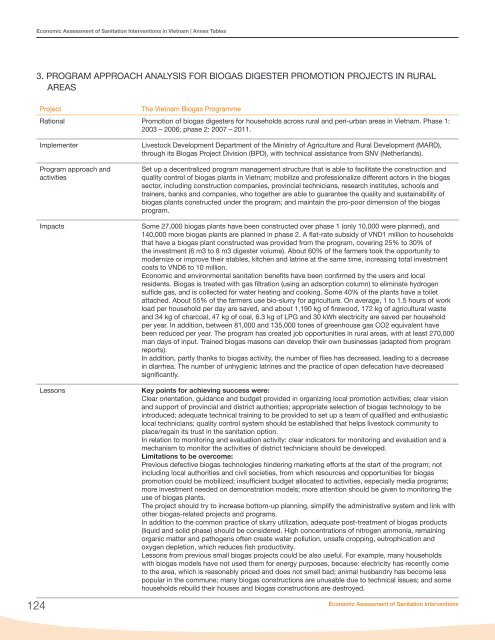

<strong>Economic</strong> <strong>Assessment</strong> <strong>of</strong> <strong>Sanitation</strong> <strong>Interventions</strong> <strong>in</strong> <strong>Vietnam</strong> | Annex Tables3. PROGRAM APPROACH ANALYSIS FOR BIOGAS DIGESTER PROMOTION PROJECTS IN RURALAREASProjectThe <strong>Vietnam</strong> Biogas ProgrammeRational Promotion <strong>of</strong> biogas digesters for households across rural and peri-urban areas <strong>in</strong> <strong>Vietnam</strong>. Phase 1:2003 – 2006; phase 2: 2007 – 2011.124ImplementerProgram approach andactivitiesImpactsLessonsLivestock Development Department <strong>of</strong> the M<strong>in</strong>istry <strong>of</strong> Agriculture and Rural Development (MARD),through its Biogas Project Division (BPD), with technical assistance from SNV (Netherlands).Set up a decentralized program management structure that is able to facilitate the construction andquality control <strong>of</strong> biogas plants <strong>in</strong> <strong>Vietnam</strong>; mobilize and pr<strong>of</strong>essionalize different actors <strong>in</strong> the biogassector, <strong>in</strong>clud<strong>in</strong>g construction companies, prov<strong>in</strong>cial technicians, research <strong>in</strong>stitutes, schools andtra<strong>in</strong>ers, banks and companies, who together are able to guarantee the quality and susta<strong>in</strong>ability <strong>of</strong>biogas plants constructed under the program; and ma<strong>in</strong>ta<strong>in</strong> the pro-poor dimension <strong>of</strong> the biogasprogram.Some 27,000 biogas plants have been constructed over phase 1 (only 10,000 were planned), and140,000 more biogas plants are planned <strong>in</strong> phase 2. A flat-rate subsidy <strong>of</strong> VND1 million to householdsthat have a biogas plant constructed was provided from the program, cover<strong>in</strong>g 25% to 30% <strong>of</strong>the <strong>in</strong>vestment (6 m3 to 8 m3 digester volume). About 60% <strong>of</strong> the farmers took the opportunity tomodernize or improve their stables, kitchen and latr<strong>in</strong>e at the same time, <strong>in</strong>creas<strong>in</strong>g total <strong>in</strong>vestmentcosts to VND6 to 10 million.<strong>Economic</strong> and environmental sanitation benefits have been confirmed by the users and localresidents. Biogas is treated with gas filtration (us<strong>in</strong>g an adsorption column) to elim<strong>in</strong>ate hydrogensulfide gas, and is collected for water heat<strong>in</strong>g and cook<strong>in</strong>g. Some 40% <strong>of</strong> the plants have a toiletattached. About 55% <strong>of</strong> the farmers use bio-slurry for agriculture. On average, 1 to 1.5 hours <strong>of</strong> workload per household per day are saved, and about 1,190 kg <strong>of</strong> firewood, 172 kg <strong>of</strong> agricultural wasteand 34 kg <strong>of</strong> charcoal, 47 kg <strong>of</strong> coal, 6.3 kg <strong>of</strong> LPG and 30 kWh electricity are saved per householdper year. In addition, between 81,000 and 135,000 tones <strong>of</strong> greenhouse gas CO2 equivalent havebeen reduced per year. The program has created job opportunities <strong>in</strong> rural areas, with at least 270,000man days <strong>of</strong> <strong>in</strong>put. Tra<strong>in</strong>ed biogas masons can develop their own bus<strong>in</strong>esses (adapted from programreports).In addition, partly thanks to biogas activity, the number <strong>of</strong> flies has decreased, lead<strong>in</strong>g to a decrease<strong>in</strong> diarrhea. The number <strong>of</strong> unhygienic latr<strong>in</strong>es and the practice <strong>of</strong> open defecation have decreasedsignificantly.Key po<strong>in</strong>ts for achiev<strong>in</strong>g success were:Clear orientation, guidance and budget provided <strong>in</strong> organiz<strong>in</strong>g local promotion activities; clear visionand support <strong>of</strong> prov<strong>in</strong>cial and district authorities; appropriate selection <strong>of</strong> biogas technology to be<strong>in</strong>troduced; adequate technical tra<strong>in</strong><strong>in</strong>g to be provided to set up a team <strong>of</strong> qualified and enthusiasticlocal technicians; quality control system should be established that helps livestock community toplace/rega<strong>in</strong> its trust <strong>in</strong> the sanitation option.In relation to monitor<strong>in</strong>g and evaluation activity: clear <strong>in</strong>dicators for monitor<strong>in</strong>g and evaluation and amechanism to monitor the activities <strong>of</strong> district technicians should be developed.Limitations to be overcome:Previous defective biogas technologies h<strong>in</strong>der<strong>in</strong>g market<strong>in</strong>g efforts at the start <strong>of</strong> the program; not<strong>in</strong>clud<strong>in</strong>g local authorities and civil societies, from which resources and opportunities for biogaspromotion could be mobilized; <strong>in</strong>sufficient budget allocated to activities, especially media programs;more <strong>in</strong>vestment needed on demonstration models; more attention should be given to monitor<strong>in</strong>g theuse <strong>of</strong> biogas plants.The project should try to <strong>in</strong>crease bottom-up plann<strong>in</strong>g, simplify the adm<strong>in</strong>istrative system and l<strong>in</strong>k withother biogas-related projects and programs.In addition to the common practice <strong>of</strong> slurry utilization, adequate post-treatment <strong>of</strong> biogas products(liquid and solid phase) should be considered. High concentrations <strong>of</strong> nitrogen ammonia, rema<strong>in</strong><strong>in</strong>gorganic matter and pathogens <strong>of</strong>ten create water pollution, unsafe cropp<strong>in</strong>g, eutrophication andoxygen depletion, which reduces fish productivity.Lessons from previous small biogas projects could be also useful. For example, many householdswith biogas models have not used them for energy purposes, because: electricity has recently cometo the area, which is reasonably priced and does not smell bad; animal husbandry has become lesspopular <strong>in</strong> the commune; many biogas constructions are unusable due to technical issues; and somehouseholds rebuild their houses and biogas constructions are destroyed.<strong>Economic</strong> <strong>Assessment</strong> <strong>of</strong> <strong>Sanitation</strong> <strong>Interventions</strong>