integration of solid oxide fuel cells and ... - Ea Energianalyse

integration of solid oxide fuel cells and ... - Ea Energianalyse

integration of solid oxide fuel cells and ... - Ea Energianalyse

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

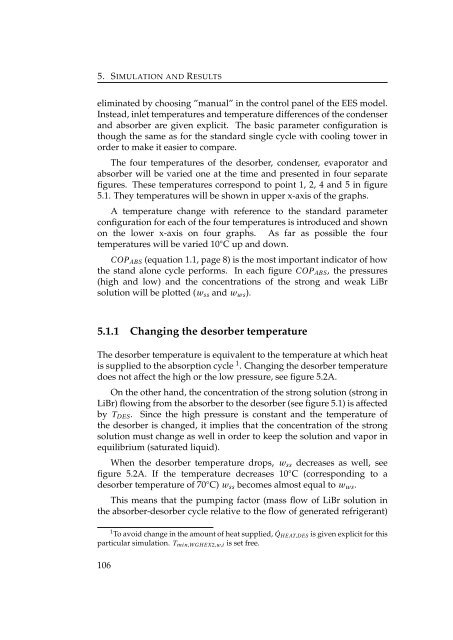

5. SIMULATION AND RESULTS<br />

eliminated by choosing ”manual” in the control panel <strong>of</strong> the EES model.<br />

Instead, inlet temperatures <strong>and</strong> temperature differences <strong>of</strong> the condenser<br />

<strong>and</strong> absorber are given explicit. The basic parameter configuration is<br />

though the same as for the st<strong>and</strong>ard single cycle with cooling tower in<br />

order to make it easier to compare.<br />

The four temperatures <strong>of</strong> the desorber, condenser, evaporator <strong>and</strong><br />

absorber will be varied one at the time <strong>and</strong> presented in four separate<br />

figures. These temperatures correspond to point 1, 2, 4 <strong>and</strong> 5 in figure<br />

5.1. They temperatures will be shown in upper x-axis <strong>of</strong> the graphs.<br />

A temperature change with reference to the st<strong>and</strong>ard parameter<br />

configuration for each <strong>of</strong> the four temperatures is introduced <strong>and</strong> shown<br />

on the lower x-axis on four graphs. As far as possible the four<br />

temperatures will be varied 10 ◦ C up <strong>and</strong> down.<br />

COP ABS (equation 1.1, page 8) is the most important indicator <strong>of</strong> how<br />

the st<strong>and</strong> alone cycle performs. In each figure COP ABS , the pressures<br />

(high <strong>and</strong> low) <strong>and</strong> the concentrations <strong>of</strong> the strong <strong>and</strong> weak LiBr<br />

solution will be plotted (w ss <strong>and</strong> w ws ).<br />

5.1.1 Changing the desorber temperature<br />

The desorber temperature is equivalent to the temperature at which heat<br />

is supplied to the absorption cycle 1 . Changing the desorber temperature<br />

does not affect the high or the low pressure, see figure 5.2A.<br />

On the other h<strong>and</strong>, the concentration <strong>of</strong> the strong solution (strong in<br />

LiBr) flowing from the absorber to the desorber (see figure 5.1) is affected<br />

by T DES . Since the high pressure is constant <strong>and</strong> the temperature <strong>of</strong><br />

the desorber is changed, it implies that the concentration <strong>of</strong> the strong<br />

solution must change as well in order to keep the solution <strong>and</strong> vapor in<br />

equilibrium (saturated liquid).<br />

When the desorber temperature drops, w ss decreases as well, see<br />

figure 5.2A. If the temperature decreases 10 ◦ C (corresponding to a<br />

desorber temperature <strong>of</strong> 70 ◦ C) w ss becomes almost equal to w ws .<br />

This means that the pumping factor (mass flow <strong>of</strong> LiBr solution in<br />

the absorber-desorber cycle relative to the flow <strong>of</strong> generated refrigerant)<br />

1 To avoid change in the amount <strong>of</strong> heat supplied, ˙Q HE AT,DES is given explicit for this<br />

particular simulation. T min,W GHE X 2,w,i is set free.<br />

106