Summary Report for Conduct of Kozloduy NPP Stress Tests

Summary Report for Conduct of Kozloduy NPP Stress Tests

Summary Report for Conduct of Kozloduy NPP Stress Tests

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

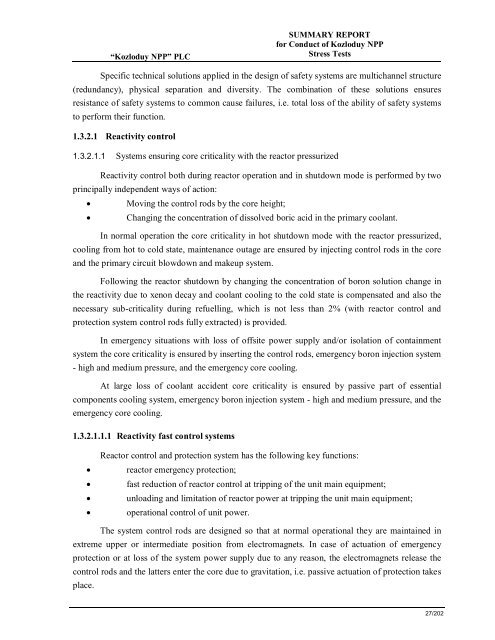

“<strong>Kozloduy</strong> <strong>NPP</strong>” PLC<br />

SUMMARY REPORT<br />

<strong>for</strong> <strong>Conduct</strong> <strong>of</strong> <strong>Kozloduy</strong> <strong>NPP</strong><br />

<strong>Stress</strong> <strong>Tests</strong><br />

Specific technical solutions applied in the design <strong>of</strong> safety systems are multichannel structure<br />

(redundancy), physical separation and diversity. The combination <strong>of</strong> these solutions ensures<br />

resistance <strong>of</strong> safety systems to common cause failures, i.e. total loss <strong>of</strong> the ability <strong>of</strong> safety systems<br />

to per<strong>for</strong>m their function.<br />

1.3.2.1 Reactivity control<br />

1.3.2.1.1 Systems ensuring core criticality with the reactor pressurized<br />

Reactivity control both during reactor operation and in shutdown mode is per<strong>for</strong>med by two<br />

principally independent ways <strong>of</strong> action:<br />

· Moving the control rods by the core height;<br />

· Changing the concentration <strong>of</strong> dissolved boric acid in the primary coolant.<br />

In normal operation the core criticality in hot shutdown mode with the reactor pressurized,<br />

cooling from hot to cold state, maintenance outage are ensured by injecting control rods in the core<br />

and the primary circuit blowdown and makeup system.<br />

Following the reactor shutdown by changing the concentration <strong>of</strong> boron solution change in<br />

the reactivity due to xenon decay and coolant cooling to the cold state is compensated and also the<br />

necessary sub-criticality during refuelling, which is not less than 2% (with reactor control and<br />

protection system control rods fully extracted) is provided.<br />

In emergency situations with loss <strong>of</strong> <strong>of</strong>fsite power supply and/or isolation <strong>of</strong> containment<br />

system the core criticality is ensured by inserting the control rods, emergency boron injection system<br />

- high and medium pressure, and the emergency core cooling.<br />

At large loss <strong>of</strong> coolant accident core criticality is ensured by passive part <strong>of</strong> essential<br />

components cooling system, emergency boron injection system - high and medium pressure, and the<br />

emergency core cooling.<br />

1.3.2.1.1.1 Reactivity fast control systems<br />

Reactor control and protection system has the following key functions:<br />

· reactor emergency protection;<br />

· fast reduction <strong>of</strong> reactor control at tripping <strong>of</strong> the unit main equipment;<br />

· unloading and limitation <strong>of</strong> reactor power at tripping the unit main equipment;<br />

· operational control <strong>of</strong> unit power.<br />

The system control rods are designed so that at normal operational they are maintained in<br />

extreme upper or intermediate position from electromagnets. In case <strong>of</strong> actuation <strong>of</strong> emergency<br />

protection or at loss <strong>of</strong> the system power supply due to any reason, the electromagnets release the<br />

control rods and the latters enter the core due to gravitation, i.e. passive actuation <strong>of</strong> protection takes<br />

place.<br />

27/202