Specifications Part 1 - Water Supply, Sewerage and Tube Well Works

Specifications Part 1 - Water Supply, Sewerage and Tube Well Works

Specifications Part 1 - Water Supply, Sewerage and Tube Well Works

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

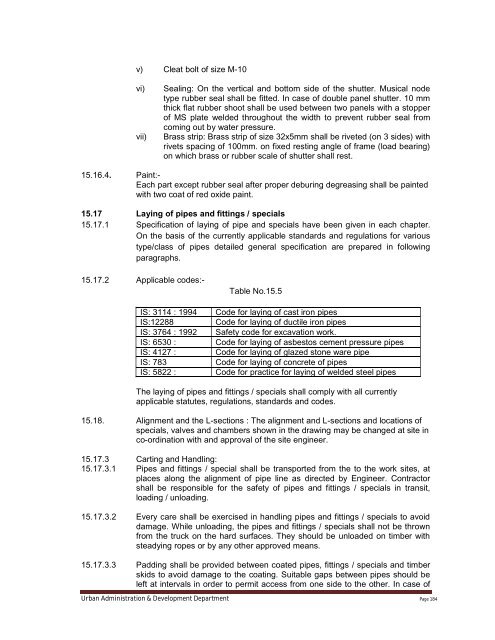

v) Cleat bolt of size M-10vi)vii)Sealing: On the vertical <strong>and</strong> bottom side of the shutter. Musical nodetype rubber seal shall be fitted. In case of double panel shutter. 10 mmthick flat rubber shoot shall be used between two panels with a stopperof MS plate welded throughout the width to prevent rubber seal fromcoming out by water pressure.Brass strip: Brass strip of size 32x5mm shall be riveted (on 3 sides) withrivets spacing of 100mm. on fixed resting angle of frame (load bearing)on which brass or rubber scale of shutter shall rest.15.16.4. Paint:-Each part except rubber seal after proper deburing degreasing shall be paintedwith two coat of red oxide paint.15.17 Laying of pipes <strong>and</strong> fittings / specials15.17.1 Specification of laying of pipe <strong>and</strong> specials have been given in each chapter.On the basis of the currently applicable st<strong>and</strong>ards <strong>and</strong> regulations for varioustype/class of pipes detailed general specification are prepared in followingparagraphs.15.17.2 Applicable codes:-IS: 3114 : 1994IS:12288IS: 3764 : 1992IS: 6530 :IS: 4127 :IS: 783IS: 5822 :Table No.15.5Code for laying of cast iron pipesCode for laying of ductile iron pipesSafety code for excavation work.Code for laying of asbestos cement pressure pipesCode for laying of glazed stone ware pipeCode for laying of concrete of pipesCode for practice for laying of welded steel pipesThe laying of pipes <strong>and</strong> fittings / specials shall comply with all currentlyapplicable statutes, regulations, st<strong>and</strong>ards <strong>and</strong> codes.15.18. Alignment <strong>and</strong> the L-sections : The alignment <strong>and</strong> L-sections <strong>and</strong> locations ofspecials, valves <strong>and</strong> chambers shown in the drawing may be changed at site inco-ordination with <strong>and</strong> approval of the site engineer.15.17.3 Carting <strong>and</strong> H<strong>and</strong>ling:15.17.3.1 Pipes <strong>and</strong> fittings / special shall be transported from the to the work sites, atplaces along the alignment of pipe line as directed by Engineer. Contractorshall be responsible for the safety of pipes <strong>and</strong> fittings / specials in transit,loading / unloading.15.17.3.2 Every care shall be exercised in h<strong>and</strong>ling pipes <strong>and</strong> fittings / specials to avoiddamage. While unloading, the pipes <strong>and</strong> fittings / specials shall not be thrownfrom the truck on the hard surfaces. They should be unloaded on timber withsteadying ropes or by any other approved means.15.17.3.3 Padding shall be provided between coated pipes, fittings / specials <strong>and</strong> timberskids to avoid damage to the coating. Suitable gaps between pipes should beleft at intervals in order to permit access from one side to the other. In case ofUrban Administration & Development Department Page 184