- Page 1 and 2:

GOVERNMENT OF MADHYA PRADESHDEPARTM

- Page 4 and 5:

Branch(i) A special form of cast ir

- Page 6 and 7:

A valve in which the closure to an

- Page 8 and 9:

Sullage waste Water:Spent water fro

- Page 10 and 11:

Laying:The approximate positions of

- Page 12 and 13:

CHAPTER NO.1CAST IRON SOCKET AND SP

- Page 14 and 15:

Socket and spigot pipes Class AWeig

- Page 16 and 17:

1.5 .4 Pipe shall be tested hydrost

- Page 18 and 19:

1.9.3 Mass (weight) of the various

- Page 20 and 21:

Diameter (mm)Weight (approx) kgHeav

- Page 22 and 23:

Diameter (mm)Weight (approx) kgHeav

- Page 24 and 25:

1.9.3.11 Cast iron plugs:-Diameter

- Page 26 and 27:

1.12.7 Caulking may be done with pn

- Page 28 and 29:

2.5 Thrust Blocks2.5.1 In case of b

- Page 30 and 31:

2.9.3 Should any test of the pipe l

- Page 32 and 33:

CHAPTER NO.3CAST IRON PIPES AND SPE

- Page 34 and 35:

3.4.2.2 Cast iron flanged spigot:-R

- Page 36 and 37: 3.4.2.6 All flanged cast iron tees:

- Page 38 and 39: Diameter (mm)Weight (approx) kgHeav

- Page 40 and 41: Nominal diameterTable 2.3Refer Tabl

- Page 42 and 43: Table No.3.8DimensionWall thickness

- Page 44 and 45: CHAPTER NO. 4DUCTILE IRON PRESSURE

- Page 46 and 47: Nominal Diameter Outer diameter of

- Page 48 and 49: 4.3.2.4 Where the coating material

- Page 50 and 51: Nominal DiameterDN (mm)Table No. 4.

- Page 52 and 53: 4.7.2.3 Lengths of FittingsThe perm

- Page 54 and 55: during the jointing operations. As

- Page 56 and 57: CHAPTER NO.5:UNPLASTICIZED PVC PIPE

- Page 58 and 59: NominaloutsideDiameter(Nominalsize)

- Page 60 and 61: 5.10 Handling and storage5.10.1 Bec

- Page 62 and 63: a)b) Size of the fitting and the ap

- Page 64 and 65: 5.14.5 Trench Bottom5.14.5.1 The tr

- Page 66 and 67: CHAPTER NO.6CAST IRON VALVES6.1 App

- Page 68 and 69: efore painting. All exposed machine

- Page 70 and 71: with the main. For large aqueduct p

- Page 72 and 73: 6.4.7 Nominal sizes :-6.4.7.1 The r

- Page 74 and 75: Table No.6.6Material for different

- Page 76 and 77: CHAPTER -7GALVANIZED IRON PIPES, SP

- Page 78 and 79: 7.4.2 Globe Valves- The globe valve

- Page 80 and 81: 7.6 Testing of valves:-7.6.1 Genera

- Page 82 and 83: NominalBoreDimensions and Nominal M

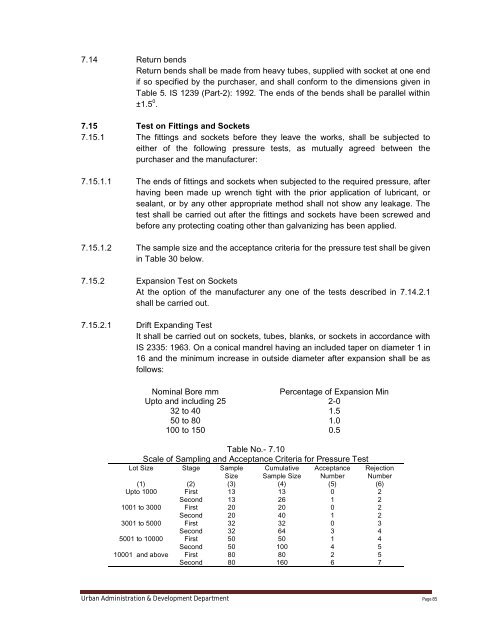

- Page 84 and 85: 7.10 Testing of Pipes :Following te

- Page 88 and 89: 7.15.2.2 Taper Screw Plug TestSocke

- Page 90 and 91: 7.20.2 All pipes and fittings shall

- Page 92 and 93: S.NoTolerance and ovality is given

- Page 94 and 95: 8.7.2 The pipe shall be as uniform

- Page 96 and 97: directional changes within the tren

- Page 98 and 99: frequently used and in normal or sl

- Page 100 and 101: 8.22 Test to Establish Perfectibili

- Page 102 and 103: 8.26.6.3 PP Saddles8.26.6.3.1 The b

- Page 104 and 105: g Bypass Pipe Carbon Steel IS1239(p

- Page 106 and 107: 9.4.1 Coupling Area of jointThis is

- Page 108 and 109: Table No. 9.3Hydrostatic Design Pre

- Page 110 and 111: polyester belts with a minimum widt

- Page 112 and 113: 9.19.4 Straight continues lengths o

- Page 114 and 115: Table No. 10.2(Refer Table No.1 IS

- Page 116 and 117: 1592-2003. The tolerances on the in

- Page 118 and 119: 10.5.2.5 Weight of cast iron plain

- Page 120 and 121: 10.5.2.9 Weight of cast iron Plain

- Page 122 and 123: 10.8.1.1 Width- The width of the tr

- Page 124 and 125: 10.11.2 Cast Iron Detachable Joints

- Page 126 and 127: shall be used between the straps an

- Page 128 and 129: 10.18.9.1 After the test has been c

- Page 130 and 131: CHAPTER NO- 11SALT GLAZED STONEWRE

- Page 132 and 133: 11.3.2 Each pipe and fittings may a

- Page 134 and 135: on each horizontal rail which is fi

- Page 136 and 137:

11.7.7 The joint with cast iron or

- Page 138 and 139:

CHAPTER NO- 12UNPLASTICIZED NON-PRE

- Page 140 and 141:

12.4 Dimensions of Pipes:12.4.1 Mea

- Page 142 and 143:

12.8 Trench:-(See Drawing No.3)12.8

- Page 144 and 145:

12.13.3 Care should be taken to lea

- Page 146 and 147:

12.17.6 HandlingFollowing Recommend

- Page 148 and 149:

12.17.10 Construction of backfill e

- Page 150 and 151:

CHAPTER - 13REINFORCED CEMENT CONCR

- Page 152 and 153:

Diameter ThicknessStrength Test Req

- Page 154 and 155:

Table 13.5(Refer Clause 8.2 IS 458

- Page 156 and 157:

efore the next pipe is laid. Adequa

- Page 158 and 159:

13.11.4 The water shall be filled t

- Page 160 and 161:

Chapter - 14SEWER APPURTENANCES14.1

- Page 162 and 163:

provided with cover of medium duty

- Page 164 and 165:

14.3.5.4.3 (c) By drop in previous

- Page 166 and 167:

14.5.3.4 Where the diameter of the

- Page 168 and 169:

14.7.4 Heavy reinforced concrete co

- Page 170 and 171:

14.11 By pass:By pass arrangements

- Page 172 and 173:

acetate paper, silt drums, ropes, i

- Page 174 and 175:

14.22. Automotive Suction Machine :

- Page 176 and 177:

14.25.3 Brick Masonry Chamber : Aft

- Page 178 and 179:

15.2.5 Lift: the vertical distance

- Page 180 and 181:

ensure that drilling has been done

- Page 182 and 183:

accepted deductions (stated as a pe

- Page 184 and 185:

described in IS 4031 (Part-5) : 198

- Page 186 and 187:

v) Cleat bolt of size M-10vi)vii)Se

- Page 188 and 189:

15.17.5.3 To protect persons from i

- Page 190 and 191:

15.17.5.19. Wherever a socket or co

- Page 192 and 193:

esults in unsuitable sub grade cond

- Page 194 and 195:

15.17.14.7 Clear out space shall be

- Page 196 and 197:

15.17.15.7.1 Ordinarily no surplus

- Page 198 and 199:

Water Supply pipes lines should be

- Page 200 and 201:

16.3.3 Failure to remove the ridge

- Page 202 and 203:

16.9.12 The cover shall be capable

- Page 204 and 205:

17.7 Development of tube-well with

- Page 206 and 207:

17.13.4 Fine enough to prevent the

- Page 208 and 209:

(iv) No. of slots per m 429(v) % Ar

- Page 210 and 211:

Annexure: ADRILLING OF TUBE WELL1.

- Page 212 and 213:

particularly those having clay or s

- Page 214 and 215:

5.3.2 The shape of the openings sho

- Page 216 and 217:

5.7.3.6.1 The contractor shall deve

- Page 218 and 219:

STRATACHATANNEXURE-2Mohalla/BastiNa

- Page 220 and 221:

LocationApparentResistivelyAB/2Inte

- Page 222 and 223:

GRAVEL PACKED TUBE WELLSGAVEL PACKE

- Page 224 and 225:

HAND PUMP PLATEFORMUrban Administra

- Page 226 and 227:

Urban Administration & Development

- Page 228 and 229:

Urban Administration & Development

- Page 230 and 231:

Urban Administration & Development

- Page 232 and 233:

Urban Administration & Development

- Page 234 and 235:

Urban Administration & Development

- Page 236 and 237:

Urban Administration & Development

- Page 238 and 239:

Urban Administration & Development

- Page 240 and 241:

Urban Administration & Development

- Page 242 and 243:

Urban Administration & Development

- Page 244 and 245:

Urban Administration & Development

- Page 246 and 247:

Urban Administration & Development

- Page 248 and 249:

Urban Administration & Development

- Page 250:

Urban Administration & Development