Specifications Part 1 - Water Supply, Sewerage and Tube Well Works

Specifications Part 1 - Water Supply, Sewerage and Tube Well Works

Specifications Part 1 - Water Supply, Sewerage and Tube Well Works

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

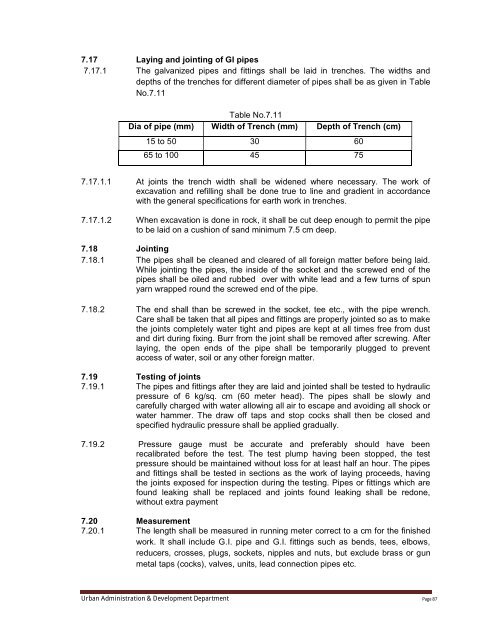

7.17 Laying <strong>and</strong> jointing of GI pipes7.17.1 The galvanized pipes <strong>and</strong> fittings shall be laid in trenches. The widths <strong>and</strong>depths of the trenches for different diameter of pipes shall be as given in TableNo.7.11Table No.7.11Dia of pipe (mm) Width of Trench (mm) Depth of Trench (cm)15 to 50 30 6065 to 100 45 757.17.1.1 At joints the trench width shall be widened where necessary. The work ofexcavation <strong>and</strong> refilling shall be done true to line <strong>and</strong> gradient in accordancewith the general specifications for earth work in trenches.7.17.1.2 When excavation is done in rock, it shall be cut deep enough to permit the pipeto be laid on a cushion of s<strong>and</strong> minimum 7.5 cm deep.7.18 Jointing7.18.1 The pipes shall be cleaned <strong>and</strong> cleared of all foreign matter before being laid.While jointing the pipes, the inside of the socket <strong>and</strong> the screwed end of thepipes shall be oiled <strong>and</strong> rubbed over with white lead <strong>and</strong> a few turns of spunyarn wrapped round the screwed end of the pipe.7.18.2 The end shall than be screwed in the socket, tee etc., with the pipe wrench.Care shall be taken that all pipes <strong>and</strong> fittings are properly jointed so as to makethe joints completely water tight <strong>and</strong> pipes are kept at all times free from dust<strong>and</strong> dirt during fixing. Burr from the joint shall be removed after screwing. Afterlaying, the open ends of the pipe shall be temporarily plugged to preventaccess of water, soil or any other foreign matter.7.19 Testing of joints7.19.1 The pipes <strong>and</strong> fittings after they are laid <strong>and</strong> jointed shall be tested to hydraulicpressure of 6 kg/sq. cm (60 meter head). The pipes shall be slowly <strong>and</strong>carefully charged with water allowing all air to escape <strong>and</strong> avoiding all shock orwater hammer. The draw off taps <strong>and</strong> stop cocks shall then be closed <strong>and</strong>specified hydraulic pressure shall be applied gradually.7.19.2 Pressure gauge must be accurate <strong>and</strong> preferably should have beenrecalibrated before the test. The test plump having been stopped, the testpressure should be maintained without loss for at least half an hour. The pipes<strong>and</strong> fittings shall be tested in sections as the work of laying proceeds, havingthe joints exposed for inspection during the testing. Pipes or fittings which arefound leaking shall be replaced <strong>and</strong> joints found leaking shall be redone,without extra payment7.20 Measurement7.20.1 The length shall be measured in running meter correct to a cm for the finishedwork. It shall include G.I. pipe <strong>and</strong> G.I. fittings such as bends, tees, elbows,reducers, crosses, plugs, sockets, nipples <strong>and</strong> nuts, but exclude brass or gunmetal taps (cocks), valves, units, lead connection pipes etc.Urban Administration & Development Department Page 87