Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Technical Reference<br />

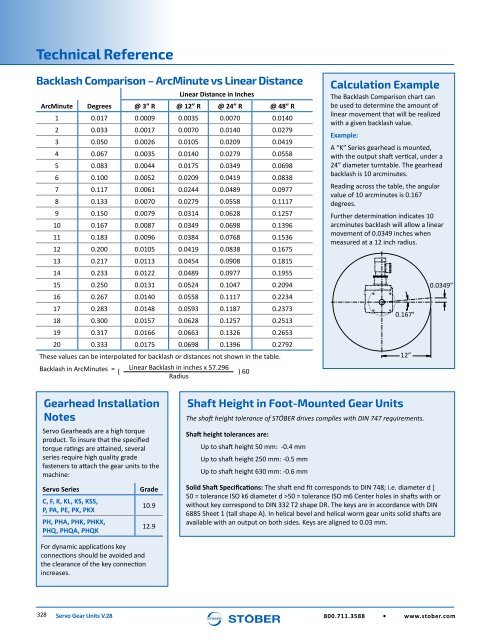

Backlash Comparison – ArcMinute vs Linear Distance<br />

Linear Distance in Inches<br />

ArcMinute Degrees @ 3” R @ 12” R @ 24” R @ 48” R<br />

1 0.017 0.0009 0.0035 0.0070 0.0140<br />

2 0.033 0.0017 0.0070 0.0140 0.0279<br />

3 0.050 0.0026 0.0105 0.0209 0.0419<br />

4 0.067 0.0035 0.0140 0.0279 0.0558<br />

5 0.083 0.0044 0.0175 0.0349 0.0698<br />

6 0.100 0.0052 0.0209 0.0419 0.0838<br />

7 0.117 0.0061 0.0244 0.0489 0.0977<br />

8 0.133 0.0070 0.0279 0.0558 0.1117<br />

9 0.150 0.0079 0.0314 0.0628 0.1257<br />

10 0.167 0.0087 0.0349 0.0698 0.1396<br />

11 0.183 0.0096 0.0384 0.0768 0.1536<br />

12 0.200 0.0105 0.0419 0.0838 0.1675<br />

13 0.217 0.0113 0.0454 0.0908 0.1815<br />

14 0.233 0.0122 0.0489 0.0977 0.1955<br />

15 0.250 0.0131 0.0524 0.1047 0.2094<br />

16 0.267 0.0140 0.0558 0.1117 0.2234<br />

17 0.283 0.0148 0.0593 0.1187 0.2373<br />

18 0.300 0.0157 0.0628 0.1257 0.2513<br />

19 0.317 0.0166 0.0663 0.1326 0.2653<br />

20 0.333 0.0175 0.0698 0.1396 0.2792<br />

These values can be interpolated for backlash or distances not shown in the table.<br />

Backlash in ArcMinutes =<br />

Linear Backlash in inches x 57.296<br />

( ) 60<br />

Radius<br />

Calculation Example<br />

The Backlash Comparison chart can<br />

be used to determine the amount of<br />

linear movement that will be realized<br />

with a given backlash value.<br />

Example:<br />

A “K” Series gearhead is mounted,<br />

with the output shaft vertical, under a<br />

24” diameter turntable. The gearhead<br />

backlash is 10 arcminutes.<br />

Reading across the table, the angular<br />

value of 10 arcminutes is 0.167<br />

degrees.<br />

Further determination indicates 10<br />

arcminutes backlash will allow a linear<br />

movement of 0.0349 inches when<br />

measured at a 12 inch radius.<br />

0.167°<br />

12”<br />

0.0349”<br />

<strong>Gear</strong>head Installation<br />

Notes<br />

<strong>Servo</strong> <strong>Gear</strong>heads are a high torque<br />

product. To insure that the specified<br />

torque ratings are attained, several<br />

series require high quality grade<br />

fasteners to attach the gear units to the<br />

machine:<br />

<strong>Servo</strong> Series<br />

C, F, K, KL, KS, KSS,<br />

P, PA, PE, PK, PKX<br />

PH, PHA, PHK, PHKX,<br />

PHQ, PHQA, PHQK<br />

Grade<br />

10.9<br />

12.9<br />

Shaft Height in Foot-Mounted <strong>Gear</strong> <strong>Units</strong><br />

The shaft height tolerance of STÖBER drives complies with DIN 747 requirements.<br />

Shaft height tolerances are:<br />

Up to shaft height 50 mm: -0.4 mm<br />

Up to shaft height 250 mm: -0.5 mm<br />

Up to shaft height 630 mm: -0.6 mm<br />

Solid Shaft Specifications: The shaft end fit corresponds to DIN 748; i.e. diameter d [<br />

50 = tolerance ISO k6 diameter d >50 = tolerance ISO m6 Center holes in shafts with or<br />

without key correspond to DIN 332 T2 shape DR. The keys are in accordance with DIN<br />

6885 Sheet 1 (tall shape A). In helical bevel and helical worm gear units solid shafts are<br />

available with an output on both sides. Keys are aligned to 0.03 mm.<br />

For dynamic applications key<br />

connections should be avoided and<br />

the clearance of the key connection<br />

increases.<br />

328 <strong>Servo</strong> <strong>Gear</strong> <strong>Units</strong> V.28 800.711.3588 • www.stober.com