part 1: overview of cogeneration and its status in asia - Fire

part 1: overview of cogeneration and its status in asia - Fire

part 1: overview of cogeneration and its status in asia - Fire

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

14 Part I: Overview <strong>of</strong> <strong>cogeneration</strong> <strong>and</strong> <strong>its</strong> <strong>status</strong> <strong>in</strong> Asia<br />

Diesel eng<strong>in</strong>es can run on a variety <strong>of</strong> fuels such as diesel, heavy fuel oil, light fuel oil, LPG,<br />

natural gas, producer gas, digester gas, etc. The diesel eng<strong>in</strong>es that are converted to gas<br />

eng<strong>in</strong>es are also known as dual-fuel eng<strong>in</strong>es. In their operation, the ma<strong>in</strong> fuel is gas, which is<br />

ignited by a small quantity <strong>of</strong> pilot oil, usually diesel oil. The pilot oil is used to make sure that<br />

the gas <strong>in</strong> the cyl<strong>in</strong>der will ignite. The gas/oil ratio is normally controlled so that the proportion<br />

<strong>of</strong> pilot oil at full eng<strong>in</strong>e power will be around 5 per cent <strong>of</strong> the fuel quantity supplied. Diesel<br />

eng<strong>in</strong>es runn<strong>in</strong>g <strong>in</strong> gas eng<strong>in</strong>e mode can be classified <strong>in</strong> another way <strong>in</strong>to two groups: lowpressure<br />

dual-fuel eng<strong>in</strong>es <strong>and</strong> high-pressure dual-fuel eng<strong>in</strong>es.<br />

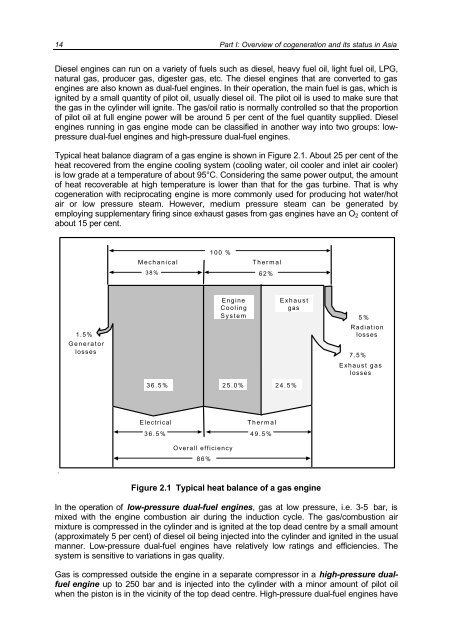

Typical heat balance diagram <strong>of</strong> a gas eng<strong>in</strong>e is shown <strong>in</strong> Figure 2.1. About 25 per cent <strong>of</strong> the<br />

heat recovered from the eng<strong>in</strong>e cool<strong>in</strong>g system (cool<strong>in</strong>g water, oil cooler <strong>and</strong> <strong>in</strong>let air cooler)<br />

is low grade at a temperature <strong>of</strong> about 95°C. Consider<strong>in</strong>g the same power output, the amount<br />

<strong>of</strong> heat recoverable at high temperature is lower than that for the gas turb<strong>in</strong>e. That is why<br />

<strong>cogeneration</strong> with reciprocat<strong>in</strong>g eng<strong>in</strong>e is more commonly used for produc<strong>in</strong>g hot water/hot<br />

air or low pressure steam. However, medium pressure steam can be generated by<br />

employ<strong>in</strong>g supplementary fir<strong>in</strong>g s<strong>in</strong>ce exhaust gases from gas eng<strong>in</strong>es have an O2 content <strong>of</strong><br />

about 15 per cent.<br />

1.5%<br />

Generator<br />

losses<br />

100 %<br />

Mechanical Thermal<br />

38%<br />

62%<br />

36.5% 25.0% 24.5%<br />

Electrical Thermal<br />

36.5% 49.5%<br />

Overall efficiency<br />

86%<br />

Eng<strong>in</strong>e<br />

Cool<strong>in</strong>g<br />

System<br />

Exhaust<br />

gas<br />

Figure 2.1 Typical heat balance <strong>of</strong> a gas eng<strong>in</strong>e<br />

5%<br />

Radiation<br />

losses<br />

7.5%<br />

Exhaust gas<br />

losses<br />

In the operation <strong>of</strong> low-pressure dual-fuel eng<strong>in</strong>es, gas at low pressure, i.e. 3-5 bar, is<br />

mixed with the eng<strong>in</strong>e combustion air dur<strong>in</strong>g the <strong>in</strong>duction cycle. The gas/combustion air<br />

mixture is compressed <strong>in</strong> the cyl<strong>in</strong>der <strong>and</strong> is ignited at the top dead centre by a small amount<br />

(approximately 5 per cent) <strong>of</strong> diesel oil be<strong>in</strong>g <strong>in</strong>jected <strong>in</strong>to the cyl<strong>in</strong>der <strong>and</strong> ignited <strong>in</strong> the usual<br />

manner. Low-pressure dual-fuel eng<strong>in</strong>es have relatively low rat<strong>in</strong>gs <strong>and</strong> efficiencies. The<br />

system is sensitive to variations <strong>in</strong> gas quality.<br />

Gas is compressed outside the eng<strong>in</strong>e <strong>in</strong> a separate compressor <strong>in</strong> a high-pressure dualfuel<br />

eng<strong>in</strong>e up to 250 bar <strong>and</strong> is <strong>in</strong>jected <strong>in</strong>to the cyl<strong>in</strong>der with a m<strong>in</strong>or amount <strong>of</strong> pilot oil<br />

when the piston is <strong>in</strong> the vic<strong>in</strong>ity <strong>of</strong> the top dead centre. High-pressure dual-fuel eng<strong>in</strong>es have