part 1: overview of cogeneration and its status in asia - Fire

part 1: overview of cogeneration and its status in asia - Fire

part 1: overview of cogeneration and its status in asia - Fire

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

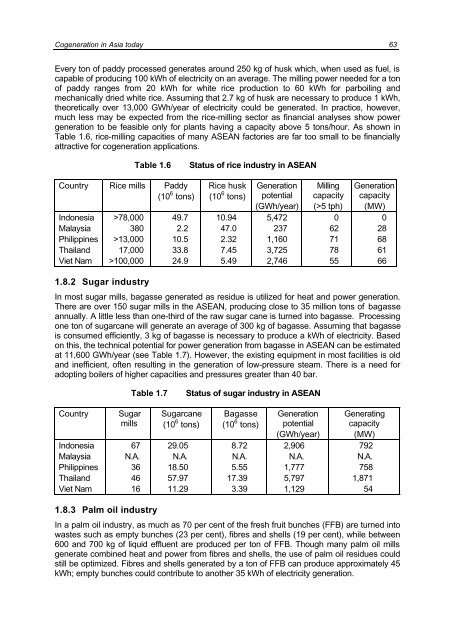

Cogeneration <strong>in</strong> Asia today 63<br />

Every ton <strong>of</strong> paddy processed generates around 250 kg <strong>of</strong> husk which, when used as fuel, is<br />

capable <strong>of</strong> produc<strong>in</strong>g 100 kWh <strong>of</strong> electricity on an average. The mill<strong>in</strong>g power needed for a ton<br />

<strong>of</strong> paddy ranges from 20 kWh for white rice production to 60 kWh for parboil<strong>in</strong>g <strong>and</strong><br />

mechanically dried white rice. Assum<strong>in</strong>g that 2.7 kg <strong>of</strong> husk are necessary to produce 1 kWh,<br />

theoretically over 13,000 GWh/year <strong>of</strong> electricity could be generated. In practice, however,<br />

much less may be expected from the rice-mill<strong>in</strong>g sector as f<strong>in</strong>ancial analyses show power<br />

generation to be feasible only for plants hav<strong>in</strong>g a capacity above 5 tons/hour. As shown <strong>in</strong><br />

Table 1.6, rice-mill<strong>in</strong>g capacities <strong>of</strong> many ASEAN factories are far too small to be f<strong>in</strong>ancially<br />

attractive for <strong>cogeneration</strong> applications.<br />

Country Rice mills Paddy<br />

(10 6 tons)<br />

Indonesia<br />

Malaysia<br />

Philipp<strong>in</strong>es<br />

Thail<strong>and</strong><br />

Viet Nam<br />

>78,000<br />

380<br />

>13,000<br />

17,000<br />

>100,000<br />

1.8.2 Sugar <strong>in</strong>dustry<br />

Table 1.6 Status <strong>of</strong> rice <strong>in</strong>dustry <strong>in</strong> ASEAN<br />

49.7<br />

2.2<br />

10.5<br />

33.8<br />

24.9<br />

Rice husk<br />

(10 6 tons)<br />

10.94<br />

47.0<br />

2.32<br />

7.45<br />

5.49<br />

Generation<br />

potential<br />

(GWh/year)<br />

5,472<br />

237<br />

1,160<br />

3,725<br />

2,746<br />

Mill<strong>in</strong>g<br />

capacity<br />

(>5 tph)<br />

0<br />

62<br />

71<br />

78<br />

55<br />

Generation<br />

capacity<br />

(MW)<br />

0<br />

28<br />

68<br />

61<br />

66<br />

In most sugar mills, bagasse generated as residue is utilized for heat <strong>and</strong> power generation.<br />

There are over 150 sugar mills <strong>in</strong> the ASEAN, produc<strong>in</strong>g close to 35 million tons <strong>of</strong> bagasse<br />

annually. A little less than one-third <strong>of</strong> the raw sugar cane is turned <strong>in</strong>to bagasse. Process<strong>in</strong>g<br />

one ton <strong>of</strong> sugarcane will generate an average <strong>of</strong> 300 kg <strong>of</strong> bagasse. Assum<strong>in</strong>g that bagasse<br />

is consumed efficiently, 3 kg <strong>of</strong> bagasse is necessary to produce a kWh <strong>of</strong> electricity. Based<br />

on this, the technical potential for power generation from bagasse <strong>in</strong> ASEAN can be estimated<br />

at 11,600 GWh/year (see Table 1.7). However, the exist<strong>in</strong>g equipment <strong>in</strong> most facilities is old<br />

<strong>and</strong> <strong>in</strong>efficient, <strong>of</strong>ten result<strong>in</strong>g <strong>in</strong> the generation <strong>of</strong> low-pressure steam. There is a need for<br />

adopt<strong>in</strong>g boilers <strong>of</strong> higher capacities <strong>and</strong> pressures greater than 40 bar.<br />

Country Sugar<br />

mills<br />

Indonesia<br />

Malaysia<br />

Philipp<strong>in</strong>es<br />

Thail<strong>and</strong><br />

Viet Nam<br />

Table 1.7 Status <strong>of</strong> sugar <strong>in</strong>dustry <strong>in</strong> ASEAN<br />

67<br />

N.A.<br />

36<br />

46<br />

16<br />

1.8.3 Palm oil <strong>in</strong>dustry<br />

Sugarcane<br />

(10 6 tons)<br />

29.05<br />

N.A.<br />

18.50<br />

57.97<br />

11.29<br />

Bagasse<br />

(10 6 tons)<br />

8.72<br />

N.A.<br />

5.55<br />

17.39<br />

3.39<br />

Generation<br />

potential<br />

(GWh/year)<br />

2,906<br />

N.A.<br />

1,777<br />

5,797<br />

1,129<br />

Generat<strong>in</strong>g<br />

capacity<br />

(MW)<br />

792<br />

N.A.<br />

758<br />

1,871<br />

54<br />

In a palm oil <strong>in</strong>dustry, as much as 70 per cent <strong>of</strong> the fresh fruit bunches (FFB) are turned <strong>in</strong>to<br />

wastes such as empty bunches (23 per cent), fibres <strong>and</strong> shells (19 per cent), while between<br />

600 <strong>and</strong> 700 kg <strong>of</strong> liquid effluent are produced per ton <strong>of</strong> FFB. Though many palm oil mills<br />

generate comb<strong>in</strong>ed heat <strong>and</strong> power from fibres <strong>and</strong> shells, the use <strong>of</strong> palm oil residues could<br />

still be optimized. Fibres <strong>and</strong> shells generated by a ton <strong>of</strong> FFB can produce approximately 45<br />

kWh; empty bunches could contribute to another 35 kWh <strong>of</strong> electricity generation.