part 1: overview of cogeneration and its status in asia - Fire

part 1: overview of cogeneration and its status in asia - Fire

part 1: overview of cogeneration and its status in asia - Fire

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Summary <strong>of</strong> country study – Bangladesh 138<br />

s<strong>in</strong>ce the <strong>in</strong>digenous energy sources will be exploited more rationally <strong>and</strong> the national power<br />

utility would have a lower burden <strong>of</strong> cop<strong>in</strong>g with the ever-<strong>in</strong>creas<strong>in</strong>g power dem<strong>and</strong>.<br />

Cogeneration <strong>in</strong> sugar mill<br />

There are 15 sugar mills <strong>in</strong> Bangladesh. These mills are owned by the government but<br />

controlled <strong>and</strong> managed by 'Bangladesh Sugar <strong>and</strong> Food Industries Corporation (BSFIC)'.<br />

Sugarcane required by each mill is collected from <strong>its</strong> surround<strong>in</strong>g areas. The <strong>in</strong>dustry meets<br />

the major requirement <strong>of</strong> country's sugar. Sugar mills also produce molasses <strong>and</strong> bagasse,<br />

two very important by-products that are used as raw materials <strong>in</strong> distilleries <strong>and</strong> paper<br />

<strong>in</strong>dustry respectively. Bagasse is also the ma<strong>in</strong> fuel for sugar mill boilers, produc<strong>in</strong>g steam<br />

that is required <strong>in</strong> the manufactur<strong>in</strong>g process <strong>of</strong> the mill. In 1993-94, these mills crushed 2.7<br />

million tons <strong>of</strong> cane, produc<strong>in</strong>g close to a million tons <strong>of</strong> bagasse.<br />

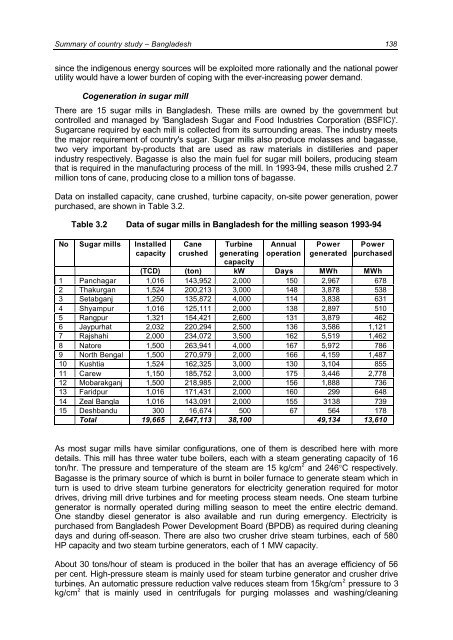

Data on <strong>in</strong>stalled capacity, cane crushed, turb<strong>in</strong>e capacity, on-site power generation, power<br />

purchased, are shown <strong>in</strong> Table 3.2.<br />

Table 3.2 Data <strong>of</strong> sugar mills <strong>in</strong> Bangladesh for the mill<strong>in</strong>g season 1993-94<br />

No Sugar mills Installed<br />

capacity<br />

Cane<br />

crushed<br />

Turb<strong>in</strong>e<br />

generat<strong>in</strong>g<br />

capacity<br />

Annual<br />

operation<br />

Power<br />

generated<br />

Power<br />

purchased<br />

(TCD) (ton) kW Days MWh MWh<br />

1 Panchagar 1,016 143,952 2,000 150 2,967 678<br />

2 Thakurgan 1,524 200,213 3,000 148 3,878 538<br />

3 Setabganj 1,250 135,872 4,000 114 3,838 631<br />

4 Shyampur 1,016 125,111 2,000 138 2,897 510<br />

5 Rangpur 1,321 154,421 2,600 131 3,879 462<br />

6 Jaypurhat 2,032 220,294 2,500 136 3,586 1,121<br />

7 Rajshahi 2,000 234,072 3,500 162 5,519 1,462<br />

8 Natore 1,500 263,941 4,000 167 5,972 786<br />

9 North Bengal 1,500 270,979 2,000 166 4,159 1,487<br />

10 Kushtia 1,524 162,325 3,000 130 3,104 855<br />

11 Carew 1,150 185,752 3,000 175 3,446 2,778<br />

12 Mobarakganj 1,500 218,985 2,000 156 1,888 736<br />

13 Faridpur 1,016 171,431 2,000 160 299 648<br />

14 Zeal Bangla 1,016 143,091 2,000 155 3138 739<br />

15 Deshb<strong>and</strong>u 300 16,674 500 67 564 178<br />

Total 19,665 2,647,113 38,100 49,134 13,610<br />

As most sugar mills have similar configurations, one <strong>of</strong> them is described here with more<br />

details. This mill has three water tube boilers, each with a steam generat<strong>in</strong>g capacity <strong>of</strong> 16<br />

ton/hr. The pressure <strong>and</strong> temperature <strong>of</strong> the steam are 15 kg/cm 2 <strong>and</strong> 246°C respectively.<br />

Bagasse is the primary source <strong>of</strong> which is burnt <strong>in</strong> boiler furnace to generate steam which <strong>in</strong><br />

turn is used to drive steam turb<strong>in</strong>e generators for electricity generation required for motor<br />

drives, driv<strong>in</strong>g mill drive turb<strong>in</strong>es <strong>and</strong> for meet<strong>in</strong>g process steam needs. One steam turb<strong>in</strong>e<br />

generator is normally operated dur<strong>in</strong>g mill<strong>in</strong>g season to meet the entire electric dem<strong>and</strong>.<br />

One st<strong>and</strong>by diesel generator is also available <strong>and</strong> run dur<strong>in</strong>g emergency. Electricity is<br />

purchased from Bangladesh Power Development Board (BPDB) as required dur<strong>in</strong>g clean<strong>in</strong>g<br />

days <strong>and</strong> dur<strong>in</strong>g <strong>of</strong>f-season. There are also two crusher drive steam turb<strong>in</strong>es, each <strong>of</strong> 580<br />

HP capacity <strong>and</strong> two steam turb<strong>in</strong>e generators, each <strong>of</strong> 1 MW capacity.<br />

About 30 tons/hour <strong>of</strong> steam is produced <strong>in</strong> the boiler that has an average efficiency <strong>of</strong> 56<br />

per cent. High-pressure steam is ma<strong>in</strong>ly used for steam turb<strong>in</strong>e generator <strong>and</strong> crusher drive<br />

turb<strong>in</strong>es. An automatic pressure reduction valve reduces steam from 15kg/cm 2 pressure to 3<br />

kg/cm 2 that is ma<strong>in</strong>ly used <strong>in</strong> centrifugals for purg<strong>in</strong>g molasses <strong>and</strong> wash<strong>in</strong>g/clean<strong>in</strong>g