part 1: overview of cogeneration and its status in asia - Fire

part 1: overview of cogeneration and its status in asia - Fire

part 1: overview of cogeneration and its status in asia - Fire

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Summary <strong>of</strong> country study – Bangladesh 149<br />

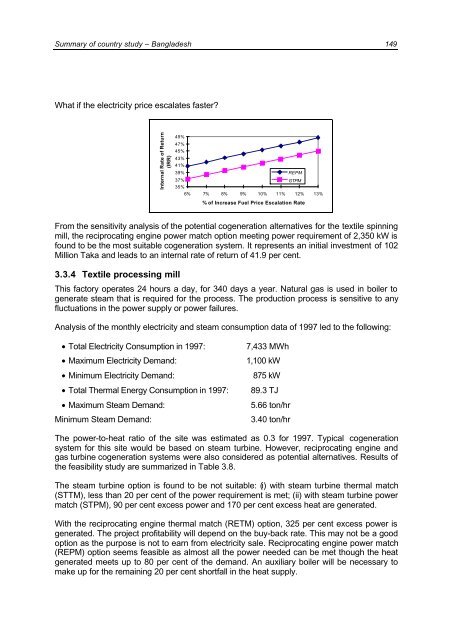

What if the electricity price escalates faster?<br />

Internal Rate <strong>of</strong> Return<br />

(IRR)<br />

49%<br />

47%<br />

45%<br />

43%<br />

41%<br />

39%<br />

37%<br />

35%<br />

REPM<br />

GTPM<br />

6% 7% 8% 9% 10% 11% 12% 13%<br />

% <strong>of</strong> Increase Fuel Price Escalation Rate<br />

From the sensitivity analysis <strong>of</strong> the potential <strong>cogeneration</strong> alternatives for the textile sp<strong>in</strong>n<strong>in</strong>g<br />

mill, the reciprocat<strong>in</strong>g eng<strong>in</strong>e power match option meet<strong>in</strong>g power requirement <strong>of</strong> 2,350 kW is<br />

found to be the most suitable <strong>cogeneration</strong> system. It represents an <strong>in</strong>itial <strong>in</strong>vestment <strong>of</strong> 102<br />

Million Taka <strong>and</strong> leads to an <strong>in</strong>ternal rate <strong>of</strong> return <strong>of</strong> 41.9 per cent.<br />

3.3.4 Textile process<strong>in</strong>g mill<br />

This factory operates 24 hours a day, for 340 days a year. Natural gas is used <strong>in</strong> boiler to<br />

generate steam that is required for the process. The production process is sensitive to any<br />

fluctuations <strong>in</strong> the power supply or power failures.<br />

Analysis <strong>of</strong> the monthly electricity <strong>and</strong> steam consumption data <strong>of</strong> 1997 led to the follow<strong>in</strong>g:<br />

• Total Electricity Consumption <strong>in</strong> 1997: 7,433 MWh<br />

• Maximum Electricity Dem<strong>and</strong>: 1,100 kW<br />

• M<strong>in</strong>imum Electricity Dem<strong>and</strong>: 875 kW<br />

• Total Thermal Energy Consumption <strong>in</strong> 1997: 89.3 TJ<br />

• Maximum Steam Dem<strong>and</strong>: 5.66 ton/hr<br />

M<strong>in</strong>imum Steam Dem<strong>and</strong>: 3.40 ton/hr<br />

The power-to-heat ratio <strong>of</strong> the site was estimated as 0.3 for 1997. Typical <strong>cogeneration</strong><br />

system for this site would be based on steam turb<strong>in</strong>e. However, reciprocat<strong>in</strong>g eng<strong>in</strong>e <strong>and</strong><br />

gas turb<strong>in</strong>e <strong>cogeneration</strong> systems were also considered as potential alternatives. Results <strong>of</strong><br />

the feasibility study are summarized <strong>in</strong> Table 3.8.<br />

The steam turb<strong>in</strong>e option is found to be not suitable: (i) with steam turb<strong>in</strong>e thermal match<br />

(STTM), less than 20 per cent <strong>of</strong> the power requirement is met; (ii) with steam turb<strong>in</strong>e power<br />

match (STPM), 90 per cent excess power <strong>and</strong> 170 per cent excess heat are generated.<br />

With the reciprocat<strong>in</strong>g eng<strong>in</strong>e thermal match (RETM) option, 325 per cent excess power is<br />

generated. The project pr<strong>of</strong>itability will depend on the buy-back rate. This may not be a good<br />

option as the purpose is not to earn from electricity sale. Reciprocat<strong>in</strong>g eng<strong>in</strong>e power match<br />

(REPM) option seems feasible as almost all the power needed can be met though the heat<br />

generated meets up to 80 per cent <strong>of</strong> the dem<strong>and</strong>. An auxiliary boiler will be necessary to<br />

make up for the rema<strong>in</strong><strong>in</strong>g 20 per cent shortfall <strong>in</strong> the heat supply.