part 1: overview of cogeneration and its status in asia - Fire

part 1: overview of cogeneration and its status in asia - Fire

part 1: overview of cogeneration and its status in asia - Fire

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

18 Part I: Overview <strong>of</strong> <strong>cogeneration</strong> <strong>and</strong> <strong>its</strong> <strong>status</strong> <strong>in</strong> Asia<br />

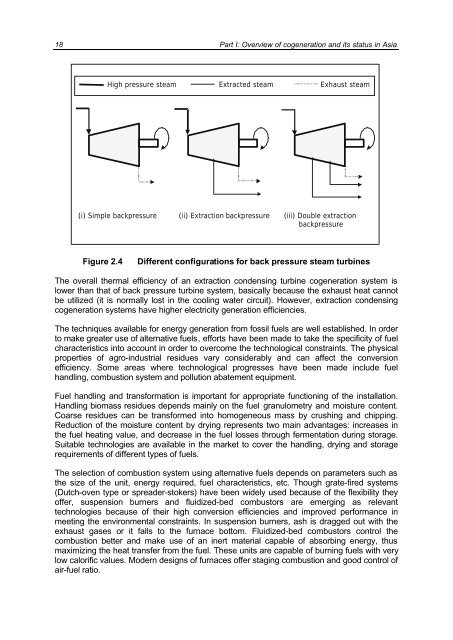

High pressure steam Extracted steam Exhaust steam<br />

(i) Simple backpressure (ii) Extraction backpressure (iii) Double extraction<br />

backpressure<br />

Figure 2.4 Different configurations for back pressure steam turb<strong>in</strong>es<br />

The overall thermal efficiency <strong>of</strong> an extraction condens<strong>in</strong>g turb<strong>in</strong>e <strong>cogeneration</strong> system is<br />

lower than that <strong>of</strong> back pressure turb<strong>in</strong>e system, basically because the exhaust heat cannot<br />

be utilized (it is normally lost <strong>in</strong> the cool<strong>in</strong>g water circuit). However, extraction condens<strong>in</strong>g<br />

<strong>cogeneration</strong> systems have higher electricity generation efficiencies.<br />

The techniques available for energy generation from fossil fuels are well established. In order<br />

to make greater use <strong>of</strong> alternative fuels, efforts have been made to take the specificity <strong>of</strong> fuel<br />

characteristics <strong>in</strong>to account <strong>in</strong> order to overcome the technological constra<strong>in</strong>ts. The physical<br />

properties <strong>of</strong> agro-<strong>in</strong>dustrial residues vary considerably <strong>and</strong> can affect the conversion<br />

efficiency. Some areas where technological progresses have been made <strong>in</strong>clude fuel<br />

h<strong>and</strong>l<strong>in</strong>g, combustion system <strong>and</strong> pollution abatement equipment.<br />

Fuel h<strong>and</strong>l<strong>in</strong>g <strong>and</strong> transformation is important for appropriate function<strong>in</strong>g <strong>of</strong> the <strong>in</strong>stallation.<br />

H<strong>and</strong>l<strong>in</strong>g biomass residues depends ma<strong>in</strong>ly on the fuel granulometry <strong>and</strong> moisture content.<br />

Coarse residues can be transformed <strong>in</strong>to homogeneous mass by crush<strong>in</strong>g <strong>and</strong> chipp<strong>in</strong>g.<br />

Reduction <strong>of</strong> the moisture content by dry<strong>in</strong>g represents two ma<strong>in</strong> advantages: <strong>in</strong>creases <strong>in</strong><br />

the fuel heat<strong>in</strong>g value, <strong>and</strong> decrease <strong>in</strong> the fuel losses through fermentation dur<strong>in</strong>g storage.<br />

Suitable technologies are available <strong>in</strong> the market to cover the h<strong>and</strong>l<strong>in</strong>g, dry<strong>in</strong>g <strong>and</strong> storage<br />

requirements <strong>of</strong> different types <strong>of</strong> fuels.<br />

The selection <strong>of</strong> combustion system us<strong>in</strong>g alternative fuels depends on parameters such as<br />

the size <strong>of</strong> the unit, energy required, fuel characteristics, etc. Though grate-fired systems<br />

(Dutch-oven type or spreader-stokers) have been widely used because <strong>of</strong> the flexibility they<br />

<strong>of</strong>fer, suspension burners <strong>and</strong> fluidized-bed combustors are emerg<strong>in</strong>g as relevant<br />

technologies because <strong>of</strong> their high conversion efficiencies <strong>and</strong> improved performance <strong>in</strong><br />

meet<strong>in</strong>g the environmental constra<strong>in</strong>ts. In suspension burners, ash is dragged out with the<br />

exhaust gases or it falls to the furnace bottom. Fluidized-bed combustors control the<br />

combustion better <strong>and</strong> make use <strong>of</strong> an <strong>in</strong>ert material capable <strong>of</strong> absorb<strong>in</strong>g energy, thus<br />

maximiz<strong>in</strong>g the heat transfer from the fuel. These un<strong>its</strong> are capable <strong>of</strong> burn<strong>in</strong>g fuels with very<br />

low calorific values. Modern designs <strong>of</strong> furnaces <strong>of</strong>fer stag<strong>in</strong>g combustion <strong>and</strong> good control <strong>of</strong><br />

air-fuel ratio.