part 1: overview of cogeneration and its status in asia - Fire

part 1: overview of cogeneration and its status in asia - Fire

part 1: overview of cogeneration and its status in asia - Fire

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Summary <strong>of</strong> country study – Viet Nam<br />

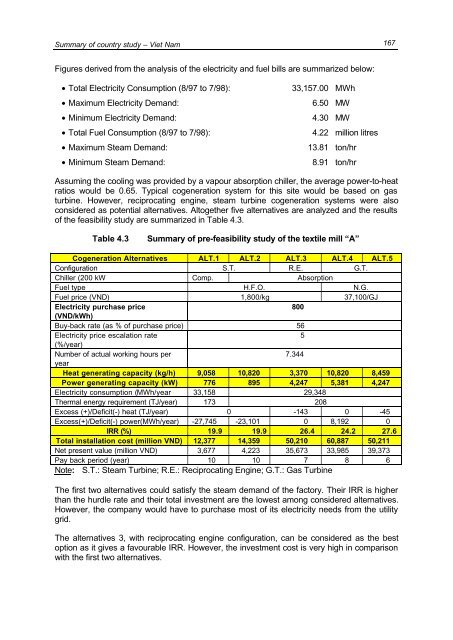

Figures derived from the analysis <strong>of</strong> the electricity <strong>and</strong> fuel bills are summarized below:<br />

• Total Electricity Consumption (8/97 to 7/98): 33,157.00 MWh<br />

• Maximum Electricity Dem<strong>and</strong>: 6.50 MW<br />

• M<strong>in</strong>imum Electricity Dem<strong>and</strong>: 4.30 MW<br />

• Total Fuel Consumption (8/97 to 7/98): 4.22 million litres<br />

• Maximum Steam Dem<strong>and</strong>: 13.81 ton/hr<br />

• M<strong>in</strong>imum Steam Dem<strong>and</strong>: 8.91 ton/hr<br />

Assum<strong>in</strong>g the cool<strong>in</strong>g was provided by a vapour absorption chiller, the average power-to-heat<br />

ratios would be 0.65. Typical <strong>cogeneration</strong> system for this site would be based on gas<br />

turb<strong>in</strong>e. However, reciprocat<strong>in</strong>g eng<strong>in</strong>e, steam turb<strong>in</strong>e <strong>cogeneration</strong> systems were also<br />

considered as potential alternatives. Altogether five alternatives are analyzed <strong>and</strong> the results<br />

<strong>of</strong> the feasibility study are summarized <strong>in</strong> Table 4.3.<br />

Table 4.3 Summary <strong>of</strong> pre-feasibility study <strong>of</strong> the textile mill “A”<br />

Cogeneration Alternatives ALT.1 ALT.2 ALT.3 ALT.4 ALT.5<br />

Configuration S.T. R.E. G.T.<br />

Chiller (200 kW Comp. Absorption<br />

Fuel type H.F.O. N.G.<br />

Fuel price (VND) 1,800/kg 37,100/GJ<br />

Electricity purchase price<br />

(VND/kWh)<br />

800<br />

Buy-back rate (as % <strong>of</strong> purchase price) 56<br />

Electricity price escalation rate<br />

(%/year)<br />

5<br />

Number <strong>of</strong> actual work<strong>in</strong>g hours per<br />

year<br />

7.344<br />

Heat generat<strong>in</strong>g capacity (kg/h) 9,058 10,820 3,370 10,820 8,459<br />

Power generat<strong>in</strong>g capacity (kW) 776 895 4,247 5,381 4,247<br />

Electricity consumption (MWh/year 33,158 29,348<br />

Thermal energy requirement (TJ/year) 173 208<br />

Excess (+)/Deficit(-) heat (TJ/year) 0 -143 0 -45<br />

Excess(+)/Deficit(-) power(MWh/year) -27,745 -23,101 0 8,192 0<br />

IRR (%) 19.9 19.9 26.4 24.2 27.6<br />

Total <strong>in</strong>stallation cost (million VND) 12,377 14,359 50,210 60,887 50,211<br />

Net present value (million VND) 3,677 4,223 35,673 33,985 39,373<br />

Pay back period (year) 10 10 7 8 6<br />

Note: S.T.: Steam Turb<strong>in</strong>e; R.E.: Reciprocat<strong>in</strong>g Eng<strong>in</strong>e; G.T.: Gas Turb<strong>in</strong>e<br />

The first two alternatives could satisfy the steam dem<strong>and</strong> <strong>of</strong> the factory. Their IRR is higher<br />

than the hurdle rate <strong>and</strong> their total <strong>in</strong>vestment are the lowest among considered alternatives.<br />

However, the company would have to purchase most <strong>of</strong> <strong>its</strong> electricity needs from the utility<br />

grid.<br />

The alternatives 3, with reciprocat<strong>in</strong>g eng<strong>in</strong>e configuration, can be considered as the best<br />

option as it gives a favourable IRR. However, the <strong>in</strong>vestment cost is very high <strong>in</strong> comparison<br />

with the first two alternatives.<br />

167