- Page 1 and 2: VMXl2N, NC~K, KC

- Page 3 and 4: FOREWORD This Supplementary Service

- Page 5 and 6: HOW TO USE THIS MANUAL CONSTRUCTION

- Page 7 and 8: .-. CONTENTS GENERAL INFORMATION ..

- Page 9 and 10: SPECIAL TOOLS The proper special to

- Page 11 and 12: ELECTRICAL Model Rectifier: Model/

- Page 13 and 14: I 30 40 50 60"F 0 5 10 15°C ENGINE

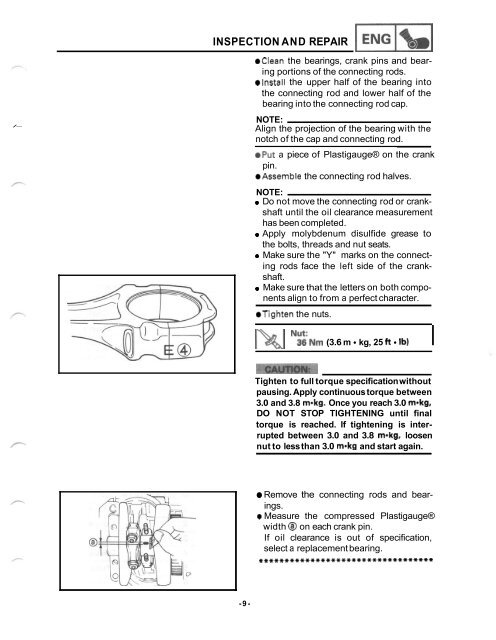

- Page 15: INSPECTION AND REPAIR a piece of Pl

- Page 19 and 20: I J5 J6 I INSPECTION AND REPAIR - 1

- Page 21 and 22: SHAFT DRIVE Dust cover Bearing hous

- Page 23 and 24: LIT-1161 6-08-77 E

- Page 25 and 26: -- NOTICE This manual was written b

- Page 27 and 28: ILLUSTRATED SYMBOLS (Refer to the i

- Page 29 and 30: MOTORCYCLE IDENTIFICATION -1- GENER

- Page 31 and 32: --- GENERAL SPECIFICATIONS SPECIFIC

- Page 33 and 34: -- LECTRICAL Model T.C.I.: Pickup c

- Page 35 and 36: FRONT FORK Front fork assembly Inne

- Page 37 and 38: ' I 342-024 -9- FRONT FORK 9.Loosen

- Page 39 and 40: -11- FRONTFORK 3.Inspect: Damper ro

- Page 41 and 42: -- -13- FRONT FORK 6.Install: Retai

- Page 43 and 44: -15- FRONT FORK 6.Install: Caliper

- Page 45 and 46: CIRCUIT DIAGRAM A.C. Magneto genera

- Page 47 and 48: 7 VMX12E/EC WIRING DIAGRAM COLOR CO

- Page 49 and 50: LIT-I1616-06-08 I

- Page 51 and 52: -- NOTICE This manual was written b

- Page 53 and 54: - MOTORCYCLE IDENTIFICATION -1- GEN

- Page 55 and 56: Exhaust "A" < Limit > Exhaust < Lim

- Page 57 and 58: LIT-1

- Page 59 and 60: NOTICE This manual was written by t

- Page 61 and 62: MOTORCYCLE I GENERAL INFORMATION RC

- Page 63 and 64: Spark Plug: Ty anufacturer Type: Mo

- Page 65 and 66: L 1616-04-67 Serr-ice I --

- Page 67 and 68:

NOTICE This manual was written by t

- Page 69 and 70:

Being a Yamaha owner, you obviously

- Page 71 and 72:

CHAPTER 1. GENERAL INFORMATION MOTO

- Page 73 and 74:

\ IMPORTANT INFORMATION IMPORTANT I

- Page 75 and 76:

- 4. Fuel Level Gauge P/N YM-01312-

- Page 77 and 78:

SPECIAL TOOLS 8. Flywheel Puller P/

- Page 79 and 80:

SPECIAL TOOLS 18. Sealant (Quick Ga

- Page 81 and 82:

-- SPECIAL TOOLS Final Drive Shaft

- Page 83 and 84:

ELECTRICAL. . . . . . . . . . . . .

- Page 85 and 86:

-- GENERAL stand pivots MAINTENANCE

- Page 87 and 88:

,-- - m VALVE CLEARANCE ADJUSTMENT

- Page 89 and 90:

TDC VALVE CLEARANCE ADJUSTMENT 360'

- Page 91 and 92:

-- INTAKE MEASURED 0.00-0.05 0.11 0

- Page 93 and 94:

FUEL FILTER REPLACEMENT/ INTAKE MAN

- Page 95 and 96:

CARBURETOR SYNCHRONIZATION NOTE: Va

- Page 97 and 98:

30 40 50 60° F ENGINE OIL LEVEL IN

- Page 99 and 100:

COOLANT LEVEL SYSTEM INSPECTION 7.

- Page 101 and 102:

FINAL GEAR OIL LEVEL INSPECTION OIL

- Page 103 and 104:

-- BRAKE FLUID LEVEL INSPECTION 3.

- Page 105 and 106:

FRONT BRAKE ADJUSTMENT/REAR BRAKE A

- Page 107 and 108:

- /-- FRONT FORK ADJUSTMENT FRONT F

- Page 109 and 110:

REAR SHOCK ABSORBER ADJUSTMENT By t

- Page 111 and 112:

RECOMMENDED COMBINATIONS OF THE FRO

- Page 113 and 114:

STEERING HEAD ADJUSTMENT 9. Remove:

- Page 115 and 116:

TIRES CHECK Be sure to install the

- Page 117 and 118:

WHEELS CHECK/IGNITION TIMING CHECK

- Page 119 and 120:

BATTERY INSPECTION 2. Remove: 3. In

- Page 121 and 122:

-- HEADLIGHT BULD REPLACEMENT NOTE:

- Page 123 and 124:

. . . CHAPTER 3. ENGINE OVERHAUL EN

- Page 125 and 126:

1 ENGINE REMOVAL ENGINE OVERHAUL EN

- Page 127 and 128:

3-3 ENGINE REMOVAL Electrical compo

- Page 129 and 130:

3-5 lead 3. Remove: Rear brake swit

- Page 131 and 132:

3-7 ENGINE REMOVAL SERVO MOTOR 1. R

- Page 133 and 134:

3-9 ENGINE DISASSEMBLY 6. Remove: (

- Page 135 and 136:

3-11 1. Remove: *Crankcase cover (l

- Page 137 and 138:

3-13 3. Straighten the lock washer

- Page 139 and 140:

3-15 ENGINE DISASSEMBLY 4. Straight

- Page 141 and 142:

3-17 ENGINE DISASSEMBLY 2. Remove:

- Page 143 and 144:

3-19 I 2 3 4 I 2 3 4 n INSPECTION A

- Page 145 and 146:

3-21 INSPECTION AND REPAIR 3. Inspe

- Page 147 and 148:

3-23 I I I I INSPECTION AND REPAIR

- Page 149 and 150:

3-25 INSPECTION AND REPAIR 10. Appl

- Page 151 and 152:

3-27 INSPECTION AND REPAIR CAMSHAFT

- Page 153 and 154:

mm INSPECTION AND REPAIR Cam Chain

- Page 155 and 156:

3-31 INSPECTION AND REPAIR 2. Posit

- Page 157 and 158:

INSPECTION AND REPAIR I I 3-33 Star

- Page 159 and 160:

3-35 INSPECTION AND REPAIR I Clutch

- Page 161 and 162:

3-37 INSPECTION AND REPAIR 4. Attac

- Page 163 and 164:

3-39 INSPECTION AND REPAIR J2 J3 J4

- Page 165 and 166:

3-41 INSPECTION AND REPAIR 3. Insta

- Page 167 and 168:

3-43 INSPECTION AND REPAIR Shift Ca

- Page 169 and 170:

3-45 MIDDLE GEAR SERVICE Drive axle

- Page 171 and 172:

MIDDLE GEAR SERVICE Exam ple: Selec

- Page 173 and 174:

3-49 U MIDDLE GEAR SERVICE 6. Tight

- Page 175 and 176:

3-51 MIDDLE GEAR SERVICE 6. Remove:

- Page 177 and 178:

3-53 MIDDLE GEAR SERVICE 3. Remove:

- Page 179 and 180:

3-55 ENGINE ASSEMBLY AND ADJUSTMENT

- Page 181 and 182:

TRANSMISSION 3-57 Bearing 1st wheel

- Page 183 and 184:

3-59 ENGINE ASSEMBLY AND ADJUSTMENT

- Page 185 and 186:

3-61 I CRANKCASE ASSEMBLY 1. Apply:

- Page 187 and 188:

3-63 Crankshaft on Unsmooth operati

- Page 189 and 190:

3-65 ENGINE ASSEMBLY AND ADJUSTMENT

- Page 191 and 192:

ENGINE ASSEMBLY AND ADJUSTMENT CLUT

- Page 193 and 194:

3-69 ENGINE ASSEMBLY AND ADJUSTMENT

- Page 195 and 196:

3-71 ENGINE ASSEMBLY AND ADJUSTMENT

- Page 197 and 198:

ENGINE ASSEMBLY AND ADJUSTMENT 4. I

- Page 199 and 200:

3-75 ENGINE ASSEMBLY AND ADJUSTMENT

- Page 201 and 202:

3-77 ENGI NE ASSEMBLY AND ADJUSTMEN

- Page 203 and 204:

3-79 ENGINE ASSEMBLY AND ADJUSTMENT

- Page 205 and 206:

3-81 ENGINE ASSEMBLY AND ADJUSTMENT

- Page 207 and 208:

-- I' CHAPTER 4. COOLING SYSTEM COO

- Page 209 and 210:

COOLANT COOLANT REPLACEMENT Do not

- Page 211 and 212:

Reservoir Tank Capacity: 0.30 L (0.

- Page 213 and 214:

-- I WATER PUMP 3. Install: pump Us

- Page 215 and 216:

A 80 (176- B I 95°C THERMOSTATIC V

- Page 217 and 218:

CYLINDER HEAD WATER JACKET RADIATOR

- Page 219 and 220:

RADIATOR AND CONDUIT 2. Inspect: *V

- Page 221 and 222:

CHAPTER 5. CARBURETION CARBURETOR .

- Page 223 and 224:

,,--- SECTION VIEW Pilot air jet No

- Page 225 and 226:

, CARBURETOR 5. Remove: brackets 6.

- Page 227 and 228:

CARBURETOR 15. Remove: Rubber caps

- Page 229 and 230:

CARBURETOR 2. Install: block NOTE:

- Page 231 and 232:

THROTTLE CABLE CYLINDER THROTTLE CA

- Page 233 and 234:

THROTTLE CABLE CYLINDER Second step

- Page 235 and 236:

-- 2. Measure: V-BOOST Betweenthe p

- Page 237 and 238:

AIR CLEANER AND CRANKCASE VENTILATI

- Page 239 and 240:

...................................

- Page 241 and 242:

REMOVAL Securely support the motorc

- Page 243 and 244:

-- FRONT WHEEL Eye protection is re

- Page 245 and 246:

REAR WHEEL seat Cylinder bearing se

- Page 247 and 248:

INSTALLATION When installing the re

- Page 249 and 250:

FRONT AND REAR BRAKE Air bleed scre

- Page 251 and 252:

FRONT AND REAR BRAKE BRAKE ONLY: Be

- Page 253 and 254:

Reservoir tank Band C opper w asher

- Page 255 and 256:

FRONT AND REAR BRAKE Rear Brake Mas

- Page 257 and 258:

FRONT AND REAR BRAKE Caliper Reasse

- Page 259 and 260:

FRONT AND REAR BRAKE NOTE: If bleed

- Page 261 and 262:

HYDRAULIC CLUTCH CLUTCH RELEASE DIS

- Page 263 and 264:

HYDRAULIC CLUTCH 3. Inspect: seal W

- Page 265 and 266:

HYDRAULIC CLUTCH i.R epeat steps (e

- Page 267 and 268:

REMOVAL FRONT FORK Securely support

- Page 269 and 270:

FRO NT FO RK NOTE: Excessive force

- Page 271 and 272:

FRONT FORK 3. Tighten: Bolt (cylind

- Page 273 and 274:

FRONT FORK 5. Adjust: Front fork ai

- Page 275 and 276:

-- REMOVAL Securely support the mot

- Page 277 and 278:

INSPECTION 1. Wash the bearing in a

- Page 279 and 280:

REAR SHOCK ABSORBER shock absorber

- Page 281 and 282:

REAR SHOCK ABSORBER 2. Install: Rea

- Page 283 and 284:

SWINGARM FREE PLAY INSPECTION 1. Re

- Page 285 and 286:

INSTALLATION When installing the sw

- Page 287 and 288:

- SHAFT DRIVE TROUBLESHOOTING The f

- Page 289 and 290:

3. Inspect: leakage By the followin

- Page 291 and 292:

1.5 mm (0.06 in) mm (3.94 in) 14 (0

- Page 293 and 294:

SHAFT DRIVE 2. Measure: Ring gear s

- Page 295 and 296:

Bearing Removal and Reassembly 1. R

- Page 297 and 298:

SHAFT DRIVE Where: a = a num eral (

- Page 299 and 300:

SHAFT DRIVE Hundredths Round I I 0

- Page 301 and 302:

SHAFT DRIVE DRIVE SHAFT Removal 1.

- Page 303 and 304:

COOLING SYSTEM ....................

- Page 305 and 306:

CIRCUIT DIAGRAM Ignition coil Cance

- Page 307 and 308:

ELECTRICAL COMPONENTS (2) Starter r

- Page 309 and 310:

ELECTRIC STARTING SYSTEM I Aforemen

- Page 311 and 312:

Troubleshooting Chart (2) THE START

- Page 313 and 314:

STARTER MOTOR TEST O-ring Brush hol

- Page 315 and 316:

,/- ELECTRIC STARTING SYSTEM 5. Ins

- Page 317 and 318:

I 22552 I I I I I ELECTRIC STARTING

- Page 319 and 320:

ELECTRIC STARTING SYSTEM NEUTRAL SW

- Page 321 and 322:

CHARGING SYSTEM Afcrementioned circ

- Page 323 and 324:

CHARGING SYSTEM CHARGINGVOLTAGE TES

- Page 325 and 326:

- MEMO- ...........................

- Page 327 and 328:

,- IGNITION SYSTEM Aforementioned c

- Page 329 and 330:

Troubleshooting Chart IGNITION SYST

- Page 331 and 332:

A 13.2 SO 1000 IGNITION SYSTEM IGNI

- Page 333 and 334:

IGNITION SYSTEM Removal 1. Remove:

- Page 335 and 336:

Aforementioned circuit diagram show

- Page 337 and 338:

H eadlight Troubleshooting Poor gro

- Page 339 and 340:

, MEMO- ...........................

- Page 341 and 342:

,--- SIGNAL SYSTEM Aforementioned c

- Page 343 and 344:

SIGNAL SYSTEM "01L LEVEL" Warning I

- Page 345 and 346:

Troubleshooting Flasher light and i

- Page 347 and 348:

-- SIGNAL SYSTEM I Switch Position

- Page 349 and 350:

COOLING SYSTEM Aforementioned circu

- Page 351 and 352:

(221 COOLING SYSTEM ELECTRIC SW ITC

- Page 353 and 354:

A COOLING SYSTEM Thermo-unit.Inspec

- Page 355 and 356:

-- /-- Aforementioned circuit diagr

- Page 357 and 358:

TROUBLESHOOTING TroubleshootingChar

- Page 359 and 360:

-- Troubleshooting Chart (3) pump i

- Page 361 and 362:

- FUEL PUMP SYSTEM Cut-out switch D

- Page 363 and 364:

Aforementioned circuit diagram show

- Page 365 and 366:

V-BOOST SYSTEM O peration There is

- Page 367 and 368:

TROUBLESHOOTING TroubleshootingChar

- Page 369 and 370:

SERVO MOTOR TEST 1. Disconnect: mot

- Page 371 and 372:

SPECIFICATIONS GENERAL SPECIFICATIO

- Page 373 and 374:

Model Shock Absorber: Front Shock A

- Page 375 and 376:

Model Valve Spring: Inner Spring: F

- Page 377 and 378:

Model Shifter: Shifter Type Guide B

- Page 379 and 380:

SPECIFICATIONS Model Cooling System

- Page 381 and 382:

1 I Part to be Tightened Crankcase

- Page 383 and 384:

Model Master Cylinder Inside Diamet

- Page 385 and 386:

Electrical Model Voltage: Ignition

- Page 387 and 388:

SPECIFICATIONS ModeI Starting Circu

- Page 389 and 390:

CONVERSION TABLES km m m cm mm CONV

- Page 391 and 392:

LUBRICATION DIAGRAM (2) 8-21 LUBRIC

- Page 393 and 394:

LUBRICATION DIAGRAM (4) LUBRICATION

- Page 395 and 396:

Fuel pump control unit Relay unit V

- Page 397 and 398:

Handlebar switch lead Diode Ignitor

- Page 399 and 400:

CABLE ROUTING Fuel filter bracket B

- Page 401 and 402:

CANISTER PIPE ROUTING To carburetor

- Page 403 and 404:

. . . . . . . . . . . . . . . . . .

- Page 405:

PROTECT YOUR INVESTMENT Use Genuine