intervention strategies for renovation of social housing estates

intervention strategies for renovation of social housing estates

intervention strategies for renovation of social housing estates

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

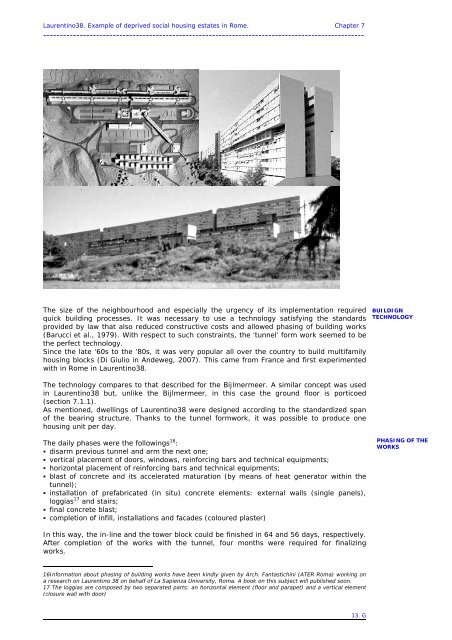

Laurentino38. Example <strong>of</strong> deprived <strong>social</strong> <strong>housing</strong> <strong>estates</strong> in Rome. Chapter 7<br />

-------------------------------------------------------------------------------------------------<br />

The size <strong>of</strong> the neighbourhood and especially the urgency <strong>of</strong> its implementation required<br />

quick building processes. It was necessary to use a technology satisfying the standards<br />

provided by law that also reduced constructive costs and allowed phasing <strong>of</strong> building works<br />

(Barucci et al., 1979). With respect to such constraints, the ‘tunnel’ <strong>for</strong>m work seemed to be<br />

the perfect technology.<br />

Since the late ‘60s to the ‘80s, it was very popular all over the country to build multifamily<br />

<strong>housing</strong> blocks (Di Giulio in Andeweg, 2007). This came from France and first experimented<br />

with in Rome in Laurentino38.<br />

The technology compares to that described <strong>for</strong> the Bijlmermeer. A similar concept was used<br />

in Laurentino38 but, unlike the Bijlmermeer, in this case the ground floor is porticoed<br />

(section 7.1.1).<br />

As mentioned, dwellings <strong>of</strong> Laurentino38 were designed according to the standardized span<br />

<strong>of</strong> the bearing structure. Thanks to the tunnel <strong>for</strong>mwork, it was possible to produce one<br />

<strong>housing</strong> unit per day.<br />

The daily phases were the followings 16 :<br />

disarm previous tunnel and arm the next one;<br />

vertical placement <strong>of</strong> doors, windows, rein<strong>for</strong>cing bars and technical equipments;<br />

horizontal placement <strong>of</strong> rein<strong>for</strong>cing bars and technical equipments;<br />

blast <strong>of</strong> concrete and its accelerated maturation (by means <strong>of</strong> heat generator within the<br />

tunnel);<br />

installation <strong>of</strong> prefabricated (in situ) concrete elements: external walls (single panels),<br />

loggias 17 and stairs;<br />

final concrete blast;<br />

completion <strong>of</strong> infill, installations and facades (coloured plaster)<br />

In this way, the in-line and the tower block could be finished in 64 and 56 days, respectively.<br />

After completion <strong>of</strong> the works with the tunnel, four months were required <strong>for</strong> finalizing<br />

works.<br />

16In<strong>for</strong>mation about phasing <strong>of</strong> building works have been kindly given by Arch. Fantastichini (ATER Roma) working on<br />

a research on Laurentino 38 on behalf <strong>of</strong> La Sapienza University, Roma. A book on this subject will published soon.<br />

17 The loggias are composed by two separated parts: an horizontal element (floor and parapet) and a vertical element<br />

(closure wall with door)<br />

13. G<br />

BUILDIGN<br />

TECHNOLOGY<br />

PHASING OF THE<br />

WORKS