- Page 1 and 2:

Hindustan Petroleum Corporation Ltd

- Page 3 and 4:

CHAPTER 1REQUEST FOR QUOTATION (RFQ

- Page 5 and 6:

Local ConditionsIt will be imperati

- Page 7:

The tender details including EMD, B

- Page 10 and 11:

his bid shall not be considered for

- Page 12 and 13:

5) This prime member shall be solel

- Page 14 and 15:

Note:1. All the information require

- Page 16 and 17:

EMD submitted by the bidder for sub

- Page 18 and 19:

however, bids in hard copies shall

- Page 20 and 21:

7.0 A firm which is not a PSU or an

- Page 22 and 23:

We are unable to bid for the reason

- Page 24 and 25:

CUT-OUT SLIPDO NOT OPEN- THIS IS A

- Page 26 and 27:

CUT-OUT SLIPDO NOT OPEN- THIS IS A

- Page 28 and 29:

QUOTATION AGAINST TENDERENQUIRY (En

- Page 30 and 31:

INDEXSR. NO.ARTICLE DESCRIPTION1.0

- Page 32 and 33:

modify the Bid Document. The amendm

- Page 34 and 35:

sealed and pasted with the enclosed

- Page 36 and 37:

l. Declaration with the bid qualifi

- Page 38 and 39:

Fax:91-22-67818080 in the presence

- Page 40 and 41:

for Part-II. In case such bidder is

- Page 42 and 43:

In case if the bidder quotes the ra

- Page 44 and 45:

xv)xvi)xvii)Non Submission of decla

- Page 46 and 47:

(c)When it is not possible to ascer

- Page 48 and 49:

14.7.2 To offset Central Sales Tax

- Page 50 and 51:

Where based on workability assessme

- Page 52 and 53:

tender terms not in deviation sheet

- Page 54 and 55:

INDEXSr. No. Article Description1.

- Page 56 and 57:

GENERAL TERMS & CONDITIONS OF CONTR

- Page 58 and 59:

2. 8 The "Drawings" shall include m

- Page 60 and 61:

3.6 The quantities indicated in the

- Page 62 and 63:

wherever required in the tender pap

- Page 64 and 65:

For working on Sundays/Holidays, th

- Page 66 and 67:

5.b COMMENCEMENT OF WORKThe contrac

- Page 68 and 69:

Contractor or the BG (if LD is full

- Page 70 and 71:

manufacture or fabrication or on th

- Page 72 and 73:

a. defects, if any, to be rectified

- Page 74 and 75:

payment of wages, salaries or other

- Page 76 and 77:

6.e.INSURANCE AND LABOURContractor

- Page 78 and 79:

iv. The contractor shall ensure tha

- Page 80 and 81:

7. PAYMENT OF CONTRACTOR'S BILLS7.

- Page 82 and 83:

shall be final and binding on the C

- Page 84 and 85:

7.e.4.Manufacturer's certificate sh

- Page 86 and 87:

accordance with the contract, the C

- Page 88 and 89:

12.0 TERMINATION OF CONTRACT12.1 Th

- Page 90 and 91:

Contractor to complete the job with

- Page 92 and 93:

shall be entitled at any time to in

- Page 94 and 95:

INDEX1. DEFINITION2. REFERENCE FOR

- Page 96 and 97:

and scope of work (technical), GPC

- Page 98 and 99:

In order to facilitate over-all exe

- Page 100 and 101:

Dimensions :For every order and eve

- Page 102 and 103:

26. CHANGESThe Owner has the option

- Page 104 and 105:

34. TECHNICAL INFORMATIONDrawings,

- Page 106 and 107:

Chapter: 4SPECIAL CONDITIONSOFCONTR

- Page 108 and 109:

44.0 DRAWINGS AND DOCUMENTS45.0 HOU

- Page 110 and 111:

viii) General Terms & Conditions of

- Page 112 and 113:

duties levied by statutory authorit

- Page 114 and 115:

stipulations including obtaining re

- Page 116 and 117:

4.1.3 Unless otherwise stated the t

- Page 118 and 119:

4.2.6 No Interest charges for delay

- Page 120 and 121:

9.0 PROVIDENT FUND, LABOUR, LABOUR

- Page 122 and 123:

not carried out work according to g

- Page 124 and 125:

16.a7 The Arbitrator may give a com

- Page 126 and 127:

19.0 Mobilization Advance19.1 Contr

- Page 128 and 129:

persons/persons or bodies/companies

- Page 130 and 131:

CONTRACTOR shall take all precautio

- Page 132 and 133:

Employer/Consultant shall not provi

- Page 134 and 135:

and return to the Contractor the st

- Page 136 and 137:

the work as per standards and all c

- Page 138 and 139:

42.0 COORDINATION WITH OTHER AGENCI

- Page 140 and 141:

pipelines, cables etc., during cons

- Page 142 and 143: Engineer-in-charge during execution

- Page 144 and 145: 56.2 All the tests either on the fi

- Page 146 and 147: The information to possible extent

- Page 148 and 149: in part or in full.e) Functional Sc

- Page 150 and 151: OWNER.66.4.4 Progress reports shall

- Page 152 and 153: Order, or material of sub-standard

- Page 154 and 155: 75.11 Co-ordination with appropriat

- Page 156 and 157: 81.2 Contractor shall develop and s

- Page 158 and 159: y them / Vendors shall be provided

- Page 160 and 161: Contractor to note that it is their

- Page 162 and 163: 3.0 APPENDICES TO SCCMH2145-C000-PS

- Page 164 and 165: SCOPE OF WORK & SUPPLY(APPENDIX-I t

- Page 166 and 167: MATHURARKPL Project OfficeHPCL Depo

- Page 168 and 169: 12. Compensatory Afforestation as p

- Page 170 and 171: TIME SCHEDULESr No Description Comp

- Page 172 and 173: MEASUREMENT OF WORK(APPENDIX-III to

- Page 174 and 175: The contractor shall submit the bil

- Page 176 and 177: 5.0 ELECTRICAL WORKS5.1 Cables5.1.1

- Page 178 and 179: TERMS OF PAYMENT(APPENDIX-IV to SCC

- Page 180 and 181: B) 5% on completion of all works in

- Page 182 and 183: 6.2.2 85% against completion of fou

- Page 184 and 185: GENERAL NOTEBefore start of work, t

- Page 186 and 187: 3.1.4 The bidder shall submit, alon

- Page 188 and 189: methodologies which he is going to

- Page 190 and 191: Bidder’s Quality PlanPO/ Contact

- Page 194 and 195: LT MOTORSSlNo. ACTIVITY CONTRACTOR

- Page 196 and 197: MLDB, LP AND PDBsSlNo. ACTIVITY CON

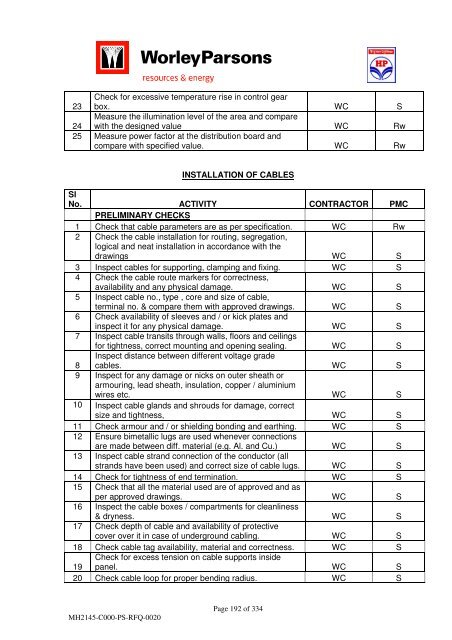

- Page 198 and 199: PRELIMINARY CHECKS1 Check that cabl

- Page 200 and 201: 1.0 INTRODUCTION2.0 SCOPEThis docum

- Page 202 and 203: 4.4 TESTINGPrior to shop prefabrica

- Page 204 and 205: 6.0 ATTACHMENT (WAIVER/DEVIATION PE

- Page 206 and 207: TO BE COMPLETED BY CUSTOMER ‘TECH

- Page 208 and 209: APPENDIX -VI TO SCCHSE MANAGEMENT P

- Page 210 and 211: INDEX1. CONDITIONS FOR ISSUE OF MAT

- Page 212 and 213: NOTE :1)Landed Rate shall be arrive

- Page 214 and 215: own cost to Owner's stores. In case

- Page 216 and 217: MINIMUM NO. OF SKILLED MANPOWER (AT

- Page 218 and 219: NOTE :-(1) The details of estimated

- Page 220 and 221: MINIMUM EQUIPMENT DEPLOYMENT PART W

- Page 222 and 223: 22 Sand/Grit Blasting Cleaning M/c.

- Page 224 and 225: 45 GPS /GIS M/c for taking the co-o

- Page 226 and 227: 8 Excavator / Back Hoe (Ex 280/ 300

- Page 228 and 229: 31 Dead Weight Tester(Ravika 0-400k

- Page 230 and 231: (2) Meeting the requirement of depl

- Page 232 and 233: EXPERIENCE CRITERIA FOR KEY PERSONN

- Page 234 and 235: 1011LEAD WELDING /NDTENGINEERWAREHO

- Page 236 and 237: 1. The Labour rates are "all inclus

- Page 238 and 239: EQUIPMENT HIRING/RECOVERY RATES(APP

- Page 240 and 241: 31. Pipe Trailers (FB / Semi Low Be

- Page 242 and 243:

INSTRUMENTS1. ELECTRONICS TRANSMITT

- Page 244 and 245:

16. SOLENOID VALVESA. AVCON CONTROL

- Page 246 and 247:

1. CENTRIFUGAL PUMPS VERTICAL - GEN

- Page 248 and 249:

G. UNIQUE INDUSTRIAL PACKINGSH. VIR

- Page 250 and 251:

K. TORMENE GAS TECHNOLOGY SPA, ITAL

- Page 252 and 253:

21. VALVE GLOBE FORGEDA. ASSOCIATED

- Page 254 and 255:

2. CABLES-CONTROL - PVCA. CCIB. FIN

- Page 256 and 257:

E. BHARTIA CUTLER HAMMER.F. CONTROL

- Page 258 and 259:

33. PERMANENT REFERENCE ELECTRODESA

- Page 260 and 261:

B. H & R JOHNSONC. BELL CERAMICSD.

- Page 262 and 263:

HINDUSTAN PETROLEUM CORPORATION LIM

- Page 264 and 265:

SR.No.A1234567BParticularsF13707 /C

- Page 266 and 267:

1 RJ/15/568 (P5322) - 24/12/2012234

- Page 268 and 269:

3NCR/GAS-O&M/DM(O&M)-152/2012/216 -

- Page 270 and 271:

2 34091/05/12-IA/728 - 3/5/2012G12H

- Page 272 and 273:

18192021222324252627282930313233342

- Page 274 and 275:

CHAPTER-5BRIEF SUMMARY OFAGREED TER

- Page 276 and 277:

(ix) Confirm acceptance of Liquidat

- Page 278 and 279:

1. Annexure-A Bid Security FormCHAP

- Page 280 and 281:

ANNEXURE-ABID SECURITY FORMBANK GUA

- Page 282 and 283:

COMPOSITE BANK GUARANTEE FOR SECURI

- Page 284 and 285:

writing.8. We, ....................

- Page 286 and 287:

ANNEXURE--DDECLARATION (NOT BANNED)

- Page 288 and 289:

ANNEXURE-FQUALIFICATION FORMAT - FO

- Page 290 and 291:

ANNEXURE-GIntegrity Pact[KK1]MH2145

- Page 292 and 293:

form part of this contract / supply

- Page 294 and 295:

INTEGRITY PACTBetweenHindustan Petr

- Page 296 and 297:

caused by him and has installed a s

- Page 298 and 299:

Section 9 — Pact DurationThis Pac

- Page 300 and 301:

MH2145-C000-PS-RFQ-0020Page 300 of

- Page 302 and 303:

MH2145-C000-PS-RFQ-0020Page 302 of

- Page 304 and 305:

Note:1. The message should be in Co

- Page 306 and 307:

3 . We ............................

- Page 308 and 309:

ANNEXURE-JBANK GUARANTEE FOR MOBILI

- Page 310 and 311:

10. "The Bank" has power to issue t

- Page 312 and 313:

servants and/or agents whatsoever t

- Page 314 and 315:

UNDERTAKING (CORPORATE/ NON-CORPORA

- Page 316 and 317:

ANNEXURE-NUNDERTAKING OF ADEQUATE C

- Page 318 and 319:

2 This Guarantee/Undertaking shall

- Page 320 and 321:

Annexure-PNAME OF SUPPLY : ……

- Page 322 and 323:

ANNEXURE - Q.1Business Rules for fi

- Page 324 and 325:

v. After the completion of English

- Page 326 and 327:

Annexure - Q.IIN.B.Terms & Conditio

- Page 328 and 329:

Annexure- Q.IIIProcess Compliance F

- Page 330 and 331:

Annexure Q.VCONTACT INFORMATION....

- Page 332 and 333:

Annexure -SCERTIFICATE OF NON-INVOL

- Page 334 and 335:

CHAPTER NO.8PRICE BID FORMATMH2145-

- Page 336 and 337:

PRICE SCHEDULE (INDIAN BIDDERS)Sche

- Page 338 and 339:

PRICE SCHEDULE (INDIAN BIDDERS)Sche

- Page 340 and 341:

PRICE SCHEDULE (INDIAN BIDDERS)Sche

- Page 342 and 343:

Item No. Item Description Unit Quan

- Page 344 and 345:

PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 346 and 347:

PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 348 and 349:

PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 350 and 351:

PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 352 and 353:

PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 354 and 355:

PRICE SCHEDULE (INDIAN BIDDERS)Sche

- Page 356 and 357:

m No. Short description Item Descri

- Page 358 and 359:

m No. Short description Item Descri

- Page 360 and 361:

m No. Short description Item Descri

- Page 362 and 363:

m No. Short description Item Descri

- Page 364 and 365:

Item No. Item Description Unit Quan

- Page 366 and 367:

UN PRICE SCHEDULE (INDIAN BIDDERS)S

- Page 368 and 369:

UN PRICE SCHEDULE (INDIAN BIDDERS)S

- Page 370 and 371:

UN PRICE SCHEDULE (INDIAN BIDDERS)S

- Page 372 and 373:

Item No.PRICE SCHEDULE (FOREIGN BID

- Page 374 and 375:

PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 376 and 377:

PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 378 and 379:

PRICE SCHEDULE (FOREIGN BIDDERS)Sch

- Page 380 and 381:

UN PRICE SCHEDULE (FOREIGN BIDDERS)